Are you gearing up for a career in Hose Seamer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Hose Seamer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

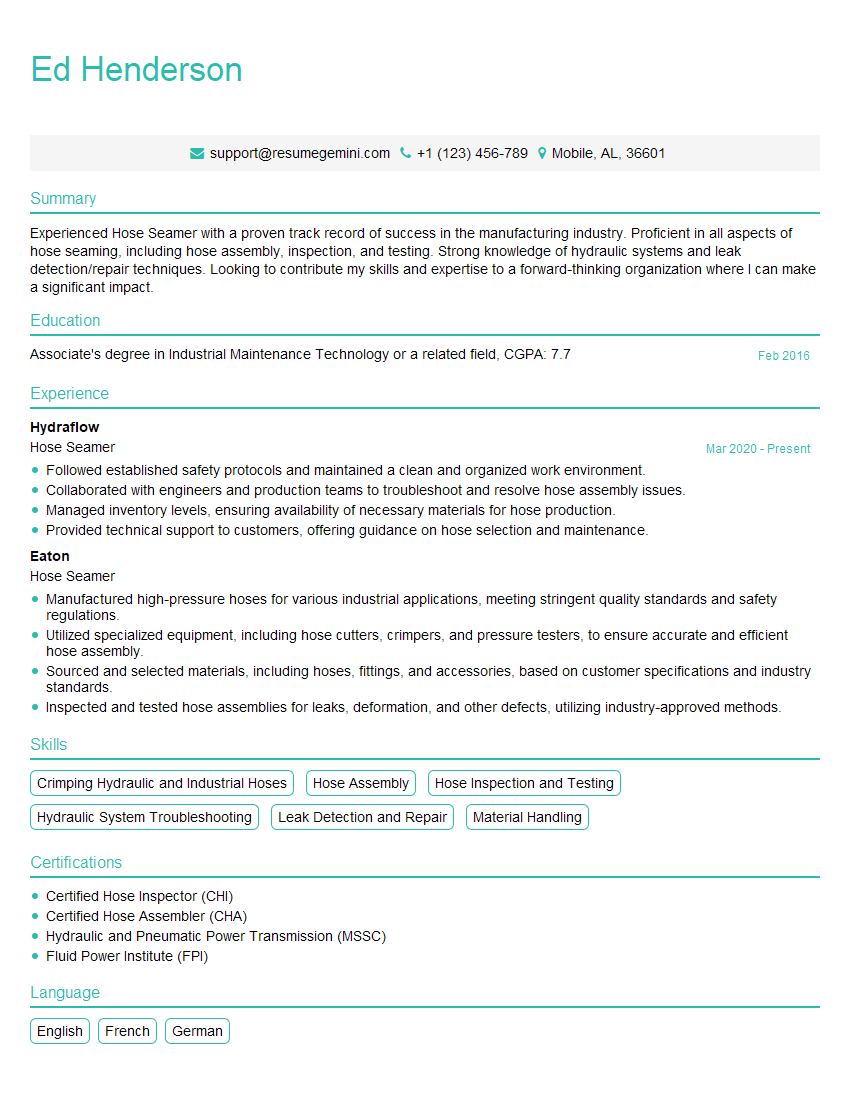

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hose Seamer

1. What are the key considerations when designing a hose seamer?

- Hose diameter and material

- Seam strength and integrity

- Production efficiency and cost

- Safety and ergonomic design

- Compatibility with existing equipment

2. Describe the different types of hose seaming methods.

- Hand seaming: Manual process using needle and thread

- Solvent seaming: Bonding materials with chemical solvents

- Impulse seaming: Using heat and pressure to fuse materials

- Ultrasonic seaming: Generating high-frequency waves to create welds

- Laser seaming: Using a focused laser beam to melt and fuse materials

3. What are the key parameters to optimize seam quality in hose seaming?

- Temperature and pressure settings

- Material overlap and alignment

- Seam speed and tension control

- Surface preparation and cleaning

- Equipment maintenance and calibration

4. How do you troubleshoot common defects in hose seams?

- Weak or brittle seams: Insufficient heat or pressure, misalignment

- Leaks or porosity: Holes or gaps in the seam, improper overlap

- Seam pull-out: Poor material adhesion, excessive tension

- Buckling or distortion: Excessive heat or tension, improper seam geometry

- Dimensional inaccuracies: Incorrect seam width or length, mismatched materials

5. What are the latest advancements and trends in hose seaming technology?

- Automated seam inspection and monitoring systems

- High-power laser seaming for increased speed and strength

- Data analytics for process optimization and defect reduction

- Development of new materials and seam designs for improved performance

- Sustainability initiatives to reduce energy consumption and waste

6. How do you ensure quality control and compliance in hose seaming operations?

- Established quality standards and procedures

- Regular equipment calibration and maintenance

- Operator training and certification

- In-process and post-process inspection

- Data traceability and documentation

7. How do you handle safety and ergonomics in hose seaming operations?

- Proper machine guarding and safety protocols

- PPE and protective equipment for operators

- Regular ergonomic assessments to prevent musculoskeletal disorders

- Training on proper lifting techniques and safe work practices

- Emergency response plans and hazard mitigation measures

8. What is your experience with implementing lean manufacturing principles in hose seaming operations?

- Value stream mapping and waste elimination

- Continuous improvement and process optimization

- Inventory reduction and just-in-time production

- Employee involvement and team-based problem-solving

- Metrics tracking and data-driven decision-making

9. How do you stay up-to-date with the latest developments in the hose seaming industry?

- Attending industry conferences and trade shows

- Reading technical journals and publications

- Networking with peers and experts

- Online research and continuing education

- Collaboration with equipment manufacturers and materials suppliers

10. What are your strengths and weaknesses as a hose seamer?

Strengths:

- Strong technical knowledge and expertise in hose seaming

- Proficient in troubleshooting and resolving production issues

- Excellent problem-solving and analytical abilities

- Committed to quality and meeting customer requirements

- Team player with effective communication and interpersonal skills

Weaknesses:

- Limited experience with certain specialized hose seaming techniques

- Not yet fluent in Spanish, but actively working on improving language skills

- Prefer to work in a structured and organized environment

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hose Seamer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hose Seamer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Hose Seamer, you will be involved in the manufacturing and assembly of flexible hoses. Your key responsibilities will include:

1. Cutting and Preparing Hoses

Carefully cut and prepare rubber or plastic hoses according to specifications.

- Use measuring tapes, rulers, and cutting tools to ensure accuracy.

- Debur and clean hose ends to prepare for assembly.

2. Assembling Hoses

Assemble hoses using various fittings, such as ferrules, couplings, and clamps.

- Apply adhesives, sealants, or gaskets to ensure a secure and leak-proof assembly.

- Follow specific torque and pressure specifications to ensure proper connections.

3. Testing and Inspecting Hoses

Conduct thorough testing and inspections to ensure the integrity of the assembled hoses.

- Perform pressure tests to verify hose strength and leak tightness.

- Inspect hoses for any defects or damage before packaging and shipment.

4. Maintenance and Repair

Perform regular maintenance and repairs on hose seaming equipment.

- Maintain a clean and organized work area to minimize downtime.

- Troubleshoot and resolve any issues with equipment to ensure optimal performance.

Interview Tips and Hacks

To ace your interview for a Hose Seamer position, consider the following tips and hacks:

1. Research the Company and Industry

Familiarize yourself with the company’s products, services, and industry trends. This will demonstrate your interest and enthusiasm for the role.

- Visit the company’s website, read industry news, and prepare specific questions about their operations.

2. Highlight Your Skills and Experience

Emphasize your relevant skills and experience, such as precision cutting, hose assembly, and quality control.

- Quantify your accomplishments and provide specific examples of your work.

- Use action verbs and avoid generic statements.

3. Prepare for Technical Questions

Expect technical questions about hose seaming processes, equipment, and troubleshooting. Be prepared to discuss your understanding of these topics.

- Review common hose seaming techniques and the types of fittings used.

4. Show Your Attention to Detail

Hose seaming requires meticulous attention to detail. Throughout the interview, demonstrate your ability to focus and follow instructions precisely.

- Dress professionally and arrive on time for your interview.

- Listen attentively to the interviewer’s questions and ask clarifying questions when needed.

5. Be Enthusiastic and Positive

Show your enthusiasm for the role and the industry. A positive attitude and a willingness to learn will make a lasting impression.

- Express your interest in the company and the opportunity to contribute to their success.

- Highlight your willingness to work hard and take on new challenges.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Hose Seamer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Hose Seamer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.