Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Hosiery Mater position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

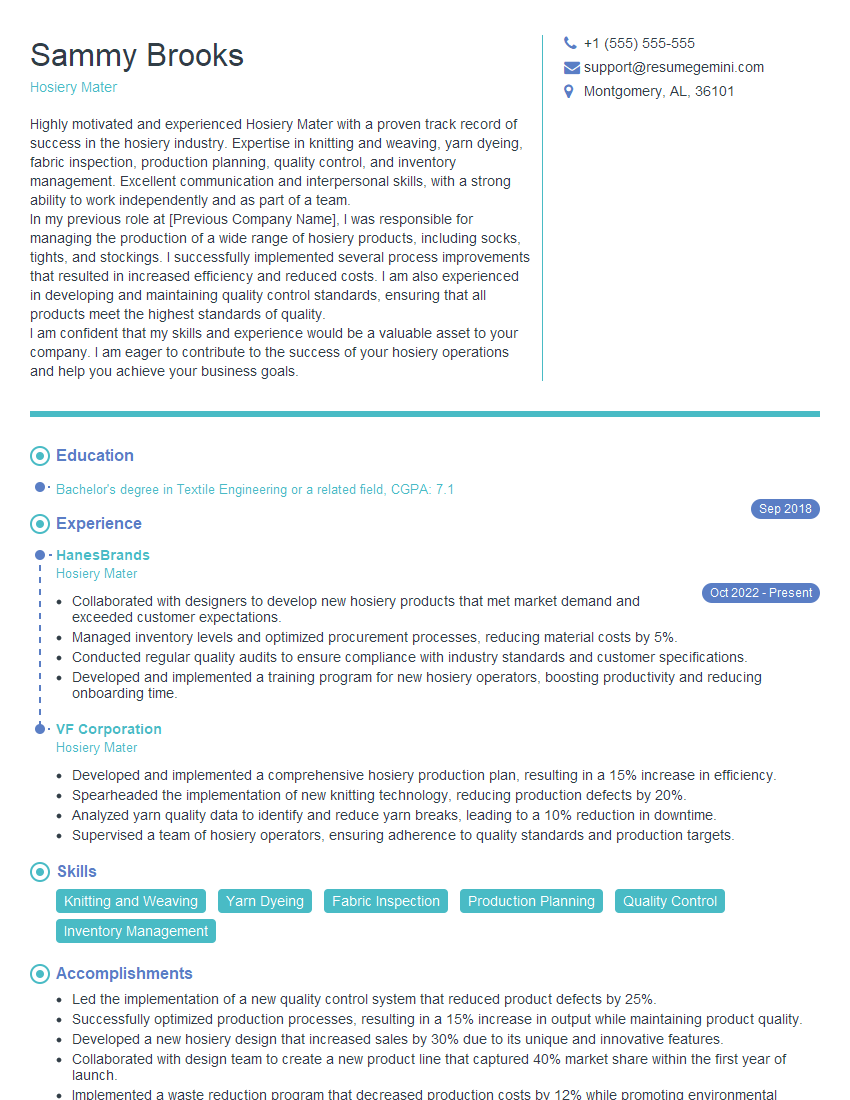

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hosiery Mater

1. What are the different types of knitting machines used in hosiery manufacturing?

In hosiery manufacturing, there are various types of knitting machines employed, each with its unique characteristics and applications. Some common types include:

- Circular knitting machines: Used to produce tubular fabrics in a continuous loop, such as socks, leggings, and pantyhose.

- Flat knitting machines: Create flat fabric panels that can be sewn together to form garments like sweaters, scarves, and hats.

- Warp knitting machines: Produce fabrics by interlocking vertical yarns (warps) and horizontal yarns (wefts), resulting in stable and durable textiles.

- Double-knitting machines: Create fabrics with two layers simultaneously, providing a thicker and more opaque result suitable for garments like sweatshirts and hoodies.

- Jacquard knitting machines: Allow for intricate patterns and designs to be integrated into fabrics through the selective activation of needles.

2. What factors influence the quality of hosiery products?

Raw materials:

The quality of the yarn used, including its fiber content, twist, and tension, significantly impacts the final product’s durability, softness, and appearance.Knitting process:

Proper machine calibration, tension control, and stitch formation are crucial for producing garments with the desired fit, shape, and texture.Dyeing and finishing:

The dyeing process can affect colorfastness, vibrancy, and the overall aesthetics of the product. Finishing treatments, such as softening and anti-pilling, enhance the comfort and durability of hosiery.Quality control:

Regular inspections and testing throughout the manufacturing process ensure that products meet the required standards for size, fit, and performance.

3. What are the key physical and mechanical properties of hosiery fabrics?

Tensile strength:

The ability of the fabric to withstand stretching without breaking, important for durability and wear resistance.Elongation at break:

The amount of stretch a fabric can undergo before rupturing, indicating its flexibility and comfort.Burst strength:

The resistance of the fabric to tearing or bursting under pressure, essential for garments subjected to high stress.Abrasion resistance:

The ability of the fabric to withstand wear and tear, affecting its longevity and appearance.Pilling resistance:

The resistance of the fabric to the formation of small, unwanted balls of fibers on the surface, maintaining its aesthetic appeal.

4. How do you troubleshoot common defects in hosiery products?

Dropped stitches:

Identifying the location of the dropped stitch and using a crochet hook or needle to manually repair it.Runs or ladders:

Using a ladder stop device or carefully sewing across the run to prevent it from spreading.Holes or tears:

Assessing the extent of the damage and using appropriate repair techniques, such as patching or darning.Dyeing issues:

Analyzing the cause of the defect, such as uneven dyeing or color bleeding, and implementing corrective measures in the dyeing process.Finishing defects:

Inspecting the product for imperfections in texture, shrinking, or pilling and addressing them through appropriate finishing treatments or adjustments.

5. What are the latest trends and innovations in hosiery manufacturing?

Sustainable materials:

Increasing use of eco-friendly fibers, such as organic cotton, recycled materials, and biodegradable yarns.Smart textiles:

Integration of sensors and conductive fibers into hosiery to enhance functionality, such as monitoring vital signs or providing warmth.3D knitting:

Advanced knitting techniques that allow for the creation of complex and seamless garments with enhanced comfort and fit.Customizable hosiery:

Personalized products tailored to individual preferences, offering a wider range of choices and improved customer satisfaction.Automated manufacturing:

Implementation of automation and robotics to streamline production processes, reduce labor costs, and improve efficiency.

6. What software and tools are commonly used in the hosiery industry?

Computer-aided design (CAD):

For designing and creating patterns, simulating knitting processes, and generating production instructions.Knitting machine programming software:

To create and optimize knitting programs that control machine settings and stitch patterns.Quality control software:

For automating inspections, tracking production data, and ensuring product consistency.Inventory management systems:

To manage raw materials, track production status, and optimize supply chain efficiency.Customer relationship management (CRM) systems:

For managing customer orders, tracking preferences, and providing personalized service.

7. What are the challenges faced by the hosiery industry?

Intense competition:

Global competition from low-cost manufacturers and the proliferation of fast fashion brands.Rising raw material costs:

Fluctuations in the prices of cotton, yarn, and other materials can impact production costs and profit margins.Technological advancements:

The need to invest in new technologies and automation to remain competitive and meet changing consumer demands.Sustainability concerns:

Consumers’ increasing awareness of environmental issues and demand for sustainable products.Supply chain disruptions:

Global supply chain disruptions can affect the availability of raw materials and finished products.

8. What strategies can hosiery manufacturers adopt to overcome these challenges?

Focus on innovation:

Investing in research and development to create new products, improve efficiency, and reduce costs.Enhance quality control:

Implementing robust quality standards and inspection processes to ensure product excellence.Optimize supply chain:

Building strong relationships with suppliers and implementing efficient inventory management practices.Embrace sustainability:

Adopting environmentally friendly practices, using recycled materials, and reducing waste.Target niche markets:

Identifying and focusing on specific customer segments with unique needs and preferences.

9. How do you stay up-to-date with the latest developments in the hosiery industry?

Industry events and trade shows:

Attending industry events to network, learn about new technologies, and gain insights from experts.Trade publications and online resources:

Subscribing to magazines, websites, and newsletters to stay informed about market trends, innovative products, and best practices.Networking with industry professionals:

Connecting with other hosiery manufacturers, suppliers, and industry experts to exchange ideas and learn from their experiences.Research and development:

Conducting ongoing research to explore new materials, production techniques, and consumer preferences.Customer feedback:

Gathering feedback from customers and conducting market research to identify areas for improvement and new product opportunities.

10. Why are you interested in this Hosiery Mater position at our company?

Your company’s reputation:

Expressing admiration for the company’s reputation for producing high-quality hosiery products and its commitment to innovation.Job responsibilities:

Showing enthusiasm for the specific responsibilities of the role, such as managing production, ensuring quality standards, and exploring new technologies.Growth opportunities:

Highlighting your interest in the company’s growth trajectory and the opportunities for professional development and career advancement.Your skills and experience:

Demonstrating how your technical expertise, industry knowledge, and leadership qualities align with the requirements of the position.Company culture:

Expressing your alignment with the company’s values, work environment, and commitment to sustainability.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hosiery Mater.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hosiery Mater‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of a Hosiery Mater

A Hosiery Mater plays a crucial role in the textile industry, overseeing the production and quality control of hosiery products such as socks, stockings, and tights. The key responsibilities of a Hosiery Mater include:

1. Production Management

The Hosiery Mater plans and manages the production process, ensuring that products are manufactured according to specifications and deadlines. Responsibilities include:

- Scheduling production runs and assigning production resources

- Monitoring production processes to identify and resolve any bottlenecks or issues

- Ensuring adherence to quality standards and production targets

2. Quality Control

The Hosiery Mater is responsible for maintaining the quality of hosiery products throughout the production process. Duties involve:

- Establishing and implementing quality control measures

- Inspecting raw materials and finished products to ensure they meet specifications

- Identifying and troubleshooting any quality issues during production

3. Product Development

The Hosiery Mater may also be involved in product development, working with designers to create new hosiery products or improve existing ones.

- Collaborating with designers to develop new product concepts

- Assessing the feasibility and marketability of new products

- Conducting trials and testing to ensure new products meet quality standards

4. Supplier Management

The Hosiery Mater is responsible for managing relationships with suppliers of raw materials and components used in hosiery production.

- Negotiating contracts and managing supplier relationships

- Ensuring that suppliers meet quality standards and delivery timelines

- Exploring and sourcing new suppliers for cost-effective and reliable materials

Interview Preparation Tips for Hosiery Mater

To ace an interview for a Hosiery Mater position, candidates should prepare thoroughly and showcase their knowledge, skills, and experience in the field. Here are some tips and hacks to help candidates prepare effectively:

1. Research the Company and Position

Gather information about the company, its products, and the specific responsibilities of the Hosiery Mater position. This will help you understand the company’s expectations and tailor your answers accordingly.

2. Practice Common Interview Questions

Prepare for common interview questions related to your experience, skills, and qualifications. Consider the following questions and prepare thoughtful responses:

- Tell us about your experience in the hosiery industry.

- Describe your role in managing production processes and ensuring quality standards.

- Share an example of a time you successfully resolved a quality issue.

- How do you stay updated with the latest trends and technologies in hosiery production?

- What are your strengths and weaknesses as a Hosiery Mater?

3. Highlight Your Relevant Skills

Emphasize your skills and experiences that are directly relevant to the Hosiery Mater role. These include:

- Production management

- Quality control

- Product development

- Supplier management

- Strong technical knowledge of hosiery production processes

4. Dress Professionally and Arrive Punctually

First impressions matter. Dress professionally for the interview and arrive punctually to demonstrate your respect for the interviewer’s time.

5. Ask Thoughtful Questions

Prepare thoughtful questions to ask the interviewer about the company, the position, and the industry. This shows your genuine interest and eagerness to learn more.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Hosiery Mater interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!