Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Hot End Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

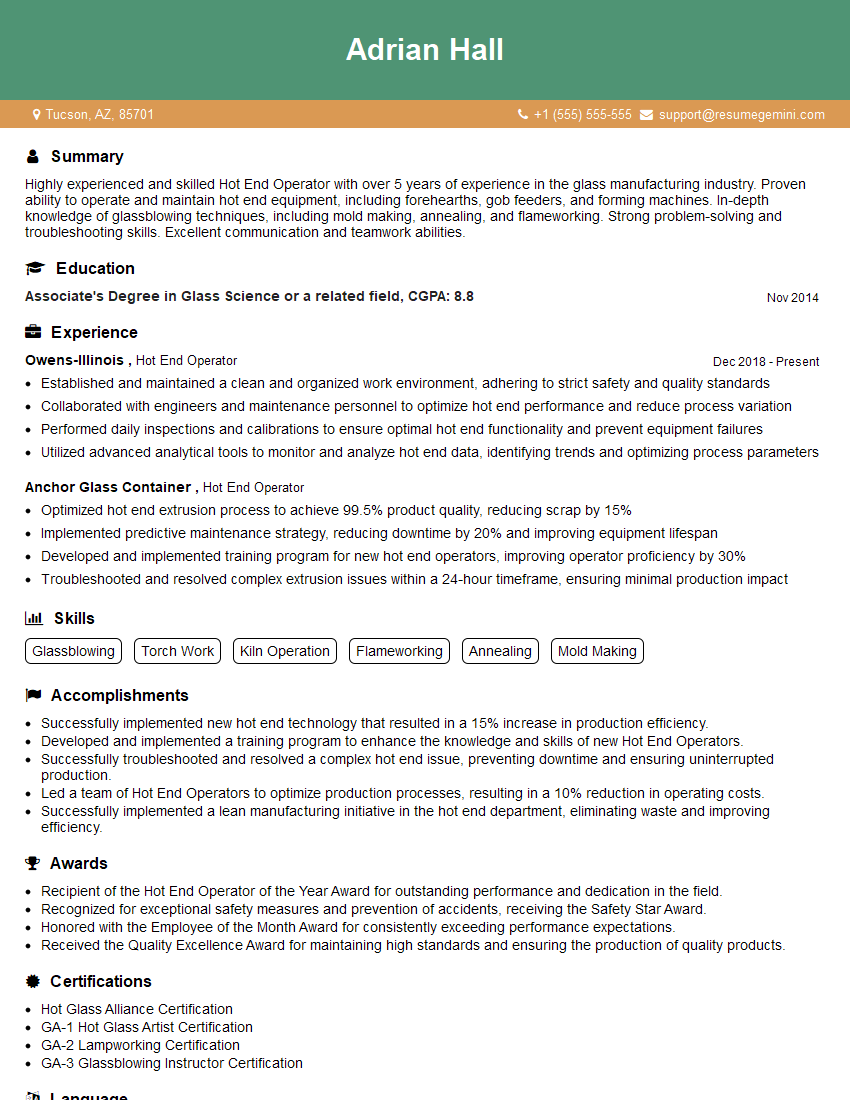

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hot End Operator

1. What are the primary responsibilities of a Hot End Operator?

- Monitor and control the temperature of the hot end of the extrusion line, ensuring it remains within specified limits.

- Inspect and maintain hot end components, including die heads, nozzles, and filters, to ensure optimal performance.

- Troubleshoot and resolve any issues related to the hot end, including blockages, temperature fluctuations, and material defects.

- Collaborate with other team members to optimize production processes and enhance product quality.

- Adhere to safety protocols and maintain a clean and organized work area.

2. How do you ensure the hot end is producing materials with the desired properties?

Monitoring and Control

- Utilize sensors and gauges to continuously monitor temperature, pressure, and flow rate.

- Make adjustments to control parameters, such as heater settings and coolant flow, based on data analysis.

Inspection and Maintenance

- Regularly inspect hot end components for wear, damage, or contamination.

- Clean filters to prevent blockages and ensure smooth material flow.

- Replace or repair damaged components promptly to maintain optimal performance.

3. How do you troubleshoot and resolve common hot end issues?

- Identify the symptoms and potential causes of the issue based on experience and technical knowledge.

- Perform diagnostic tests, such as pressure checks or flow rate analysis, to pinpoint the root cause.

- Implement appropriate corrective actions, such as clearing blockages, adjusting settings, or replacing faulty components.

- Monitor the issue closely after resolution to ensure it has been effectively addressed.

4. What are the key safety considerations when operating a hot end?

- Wear appropriate personal protective equipment, including heat-resistant gloves, apron, and safety glasses.

- Follow established safety protocols for handling hot materials and hazardous substances.

- Maintain a clean and organized work area to prevent tripping or slipping hazards.

- Be aware of potential fire hazards and have firefighting equipment readily available.

- Report any safety concerns or incidents promptly to supervisors.

5. How do you ensure that your maintenance and troubleshooting efforts are effective and do not disrupt production?

- Plan maintenance activities during scheduled downtime or low-production periods.

- Coordinate with other team members to minimize the impact on production.

- Prioritize critical maintenance tasks to ensure uninterrupted operation.

- Document all maintenance and troubleshooting activities for future reference and analysis.

- Collaborate with engineers to implement preventative measures and reduce the frequency of breakdowns.

6. What techniques do you use to optimize hot end performance and minimize material waste?

- Fine-tune temperature profiles to reduce thermal degradation and improve product quality.

- Calibrate sensors and gauges regularly to ensure accurate monitoring and control.

- Implement preventive maintenance schedules to identify and address potential issues early on.

- Monitor material flow rates and adjust settings to minimize scrap and optimize production yield.

- Collaborate with suppliers to select the most suitable materials for the process.

7. How do you handle situations where the hot end experiences unexpected fluctuations in temperature or pressure?

- Remain calm and assess the situation quickly to determine the potential cause.

- Initiate immediate corrective actions, such as adjusting settings or clearing blockages.

- Communicate the issue to supervisors and seek assistance if necessary.

- Monitor the situation closely and make further adjustments as required.

- Document the incident and any actions taken for future reference and analysis.

8. Describe your experience with different types of hot end systems.

- List the specific types of hot end systems you have worked with.

- Highlight the key differences between these systems and their applications.

- Explain how your experience with each system has equipped you for this role.

9. Explain your understanding of the principles of polymer extrusion and how it applies to hot end operation.

- Describe the basic principles of polymer extrusion, including melting, shearing, and cooling.

- Explain how these principles influence the temperature and pressure requirements of the hot end.

- Discuss the impact of material properties, such as viscosity and elasticity, on hot end operation.

10. What is your approach to continuous improvement and staying up-to-date with advancements in hot end technology?

- Attend industry conferences and workshops to learn about new technologies and best practices.

- Read technical articles and publications to stay informed about advancements in the field.

- Collaborate with colleagues to share knowledge and identify areas for improvement.

- Actively seek feedback from supervisors and peers to enhance my skills and performance.

- Contribute to continuous improvement initiatives within the organization.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hot End Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hot End Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Hot End Operator is responsible for controlling and monitoring the hot end of a glass manufacturing furnace. This involves operating and maintaining the furnace, as well as monitoring the quality of the glass being produced. Key job responsibilities include:1. Operating the furnace

The Hot End Operator is responsible for operating the furnace, including starting it up, shutting it down, and maintaining the correct temperature and pressure. This involves monitoring the furnace’s controls, making adjustments as necessary, and troubleshooting any problems that may arise.

- Starts up and shuts down the furnace, ensuring the proper operating conditions.

- Monitors furnace temperatures and pressures to maintain optimal glass quality.

- Adjusts burner settings and controls fuel flow to ensure proper combustion and heat distribution.

2. Maintaining the furnace

In addition to operating the furnace, the Hot End Operator is also responsible for maintaining it. This involves cleaning and inspecting the furnace and its components, as well as replacing parts as necessary. The Hot End Operator must also follow safety procedures and be aware of potential hazards in the workplace.

- Inspects furnace components for wear and tear, including burners, electrodes, and belts.

- Performs routine maintenance tasks, such as cleaning, lubricating, and replacing worn-out parts.

- Conducts regular safety inspections and follows established safety protocols to minimize risks.

3. Monitoring the quality of the glass

The Hot End Operator is also responsible for monitoring the quality of the glass being produced. This involves inspecting the glass for defects, and taking corrective action if necessary. The Hot End Operator should be familiar with the different types of glass defects, and know how to prevent them from occurring.

- Inspects glass products for defects, such as bubbles, cracks, and inconsistencies.

- Adjusts furnace settings or parameters to correct glass quality issues and maintain product specifications.

- Collaborates with Quality Control team to identify and resolve quality problems.

4. Keeping records

The Hot End Operator is responsible for keeping records of the furnace’s operation and maintenance. These records can be used to track the furnace’s performance, and to identify any problems that may need to be addressed.

- Records furnace operating parameters, such as temperature, pressure, and fuel consumption.

- Documents maintenance activities, including parts replaced, repairs performed, and any adjustments made.

- Maintains accurate records for future reference and audits.

Interview Tips

Preparing for an interview for a Hot End Operator position can be daunting, but by following a few simple tips, you can increase your chances of success.

1. Research the company and the position

Before you go on an interview, it is important to research the company and the position you are applying for. This will help you understand the company’s culture, its products and services, and the specific requirements of the job. You can research the company’s website, read articles about the company, and talk to people who work there.

2. Practice answering common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is important to practice answering these questions in a clear and concise way. You can practice with a friend or family member, or you can use online resources.

3. Be prepared to talk about your experience and skills

The interviewer will want to know about your experience and skills, so be prepared to talk about them in detail. This is your chance to highlight your qualifications and show the interviewer why you are the best person for the job.

4. Dress professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing a suit or business casual attire. You should also make sure that your clothes are clean and pressed.

5. Be on time

Punctuality is important, so make sure that you arrive for your interview on time. This shows the interviewer that you are respectful of their time.

6. Be confident

Confidence is key in any interview. Believe in yourself and your abilities, and let the interviewer know that you are the best person for the job.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Hot End Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!