Feeling lost in a sea of interview questions? Landed that dream interview for Hot Metal Car Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Hot Metal Car Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

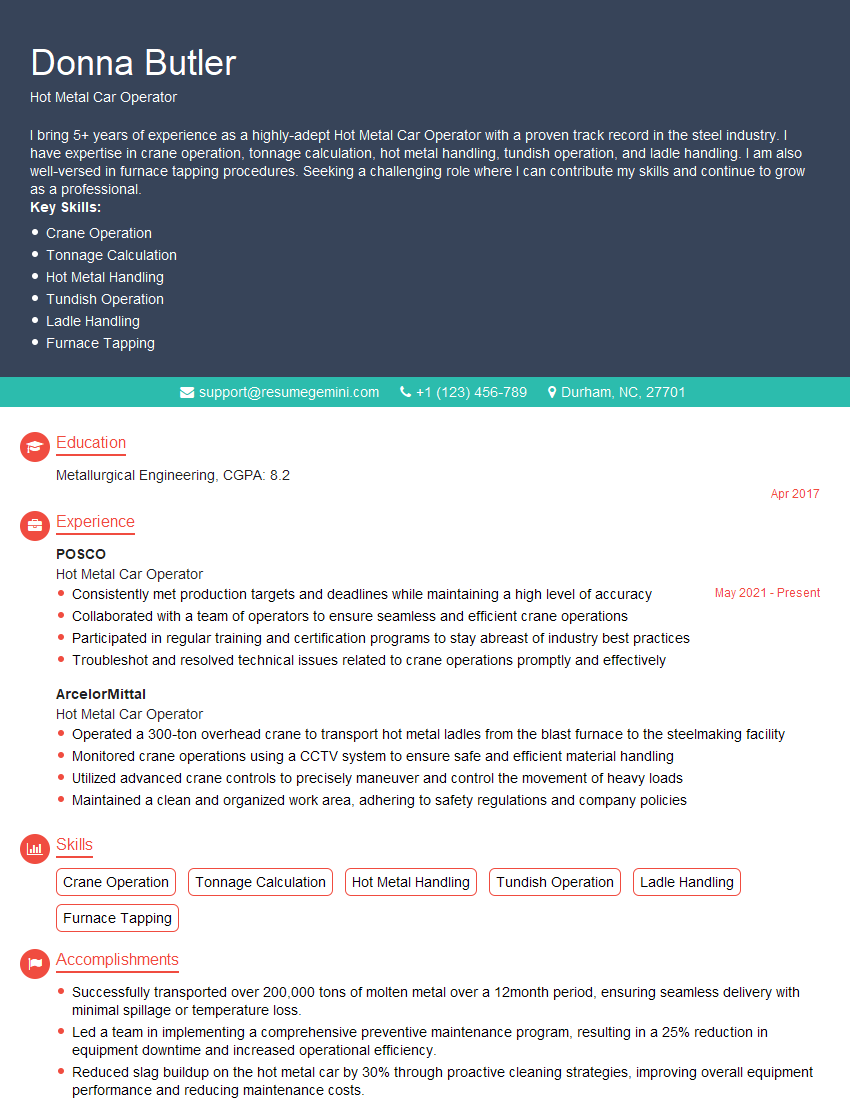

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hot Metal Car Operator

1. Describe the key responsibilities of a Hot Metal Car Operator.

As an experienced Hot Metal Car Operator, I am responsible for:

- Operating hot metal cars to transport molten iron from the blast furnace to various steelmaking facilities.

- Controlling the temperature and flow of molten iron to ensure it is delivered in the desired condition.

- Adhering to safety protocols to prevent accidents and protect workers.

- Inspecting and maintaining hot metal cars to ensure they are in good working order.

- Troubleshooting and resolving operational issues to maintain efficient production.

2. Explain the factors that affect the temperature of molten iron during transportation.

Heat Loss

- Exposure to ambient air

- Thermal conductivity of the hot metal car

- Insulation efficiency

Heat Generation

- Exothermic reactions in the molten iron

- Friction between the molten iron and the hot metal car

3. Discuss the importance of accurate temperature control in hot metal transportation.

Accurate temperature control is critical for several reasons:

- Quality of Steel: The temperature of molten iron influences the metallurgical properties of the steel produced.

- Refractory Health: Excessive temperatures can damage refractory linings in furnaces and ladles.

- Safety: Overheating can lead to explosions or uncontrolled spills.

- Efficiency: Maintaining optimal temperatures reduces energy consumption and improves productivity.

4. Describe the safety precautions that must be taken when operating hot metal cars.

Safety is paramount when operating hot metal cars. I strictly adhere to the following precautions:

- Wearing appropriate personal protective equipment (PPE) including heat-resistant clothing, gloves, and mask.

- Maintaining a safe distance from molten iron.

- Using designated walkways and avoiding hazardous areas.

- Following established emergency procedures.

- Undergoing regular training and refresher courses.

5. How do you ensure that hot metal cars are properly maintained and inspected?

Regular maintenance and inspection are crucial to ensure safe and efficient operation. I follow a comprehensive program that includes:

- Daily Inspections: Visual checks for any damage, leaks, or loose connections.

- Weekly Inspections: Detailed inspections of hydraulic systems, brakes, and electrical components.

- Monthly Inspections: Thorough inspections of the car’s body, refractory lining, and temperature sensors.

- Scheduled Overhauls: Periodic inspections and repairs to address any major issues.

- Maintenance Records: Maintaining detailed logs of all inspections and repairs performed.

6. Can you explain the process of troubleshooting and resolving operational issues with hot metal cars?

To troubleshoot and resolve operational issues, I follow a systematic approach:

- Identify the Problem: Observe and analyze the symptoms to determine the cause of the issue.

- Isolate the Cause: Conduct tests and inspections to narrow down the source of the problem.

- Develop a Solution: Determine the necessary repairs or adjustments to resolve the issue.

- Implement the Solution: Safely and effectively carry out the required repairs or adjustments.

- Verify the Fix: Test the hot metal car to ensure the issue has been resolved.

7. How do you prioritize tasks and manage workload when operating several hot metal cars simultaneously?

To effectively manage multiple hot metal cars, I prioritize tasks based on:

- Criticality: Urgent tasks or issues that require immediate attention.

- Time Sensitivity: Jobs with strict deadlines or schedules.

- Safety: Maintenance or repairs that could impact safety or production.

- Efficiency: Optimizing the utilization of hot metal cars and minimizing downtime.

8. Describe how you communicate and collaborate with other team members in a fast-paced steelmaking environment.

Effective communication and collaboration are essential in our team:

- Clear Communication: Using precise language and active listening to ensure understanding.

- Regular Meetings: Participating in shift handover meetings and daily briefings.

- Information Sharing: Exchanging knowledge, ideas, and observations to improve teamwork.

- Problem Solving: Working together to resolve operational issues and implement solutions.

- Support and Assistance: Providing and receiving support to colleagues in times of need.

9. How do you stay abreast of new technologies and best practices in the hot metal transportation industry?

To stay updated, I engage in the following activities:

- Industry Publications: Reading trade journals and attending conferences.

- Manufacturer Updates: Consulting with equipment manufacturers for product advancements and maintenance recommendations.

- Training and Development: Participating in workshops and seminars to enhance skills.

- Knowledge Sharing: Discussing best practices with colleagues and industry professionals.

- Continuous Improvement: Seeking opportunities to improve processes and safety measures.

10. In your previous role as a Hot Metal Car Operator, what was your most significant achievement?

One of my most notable achievements was implementing a new temperature monitoring system in collaboration with the maintenance team. This system provided real-time data on molten iron temperatures during transportation, allowing us to:

- Improve Temperature Control: Enhance the accuracy and reliability of temperature readings.

- Reduce Rejections: Minimize the risk of quality issues due to temperature variations.

- Optimize Energy Efficiency: Identify areas where temperature could be reduced without compromising steel quality.

- Increase Safety: Provide early warnings of potential overheating situations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hot Metal Car Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hot Metal Car Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Hot Metal Car Operators are responsible for operating and maintaining hot metal cars, which are used to transport molten metal from blast furnaces to steelmaking facilities.

1. Operate Hot Metal Cars

Hot Metal Car Operators are responsible for the safe and efficient operation of hot metal cars. This includes:

- Starting and stopping the hot metal car

- Controlling the speed and direction of the hot metal car

- Positioning the hot metal car for loading and unloading

2. Maintain Hot Metal Cars

Hot Metal Car Operators are also responsible for the maintenance of hot metal cars. This includes:

- Inspecting hot metal cars for damage

- Making minor repairs to hot metal cars

- Lubricating and greasing hot metal cars

3. Train New Employees

Hot Metal Car Operators may be responsible for training new employees. This includes:

- Providing new employees with instruction on the safe and efficient operation of hot metal cars

- Answering questions from new employees

- Supervising new employees

4. Follow Safety Procedures

Hot Metal Car Operators are responsible for following all safety procedures. This includes:

- Wearing appropriate personal protective equipment

- Following all lockout/tagout procedures

- Reporting any unsafe conditions

Interview Tips

Preparing for an interview can be daunting, but there are a few things you can do to increase your chances of success.

1. Research the Company and the Position

Before you go on an interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture, values, and goals. You should also be able to articulate why you are interested in the position and how your skills and experience match the job requirements.

2. Practice Answering Common Interview Questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice answering these questions in advance so that you can deliver your answers confidently and clearly.

3. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for a business setting.

4. Be on Time

Punctuality is important, so make sure to arrive for your interview on time. If you are running late, be sure to call or email the interviewer to let them know.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Hot Metal Car Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!