Are you gearing up for a career in Hot Mill Roller? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Hot Mill Roller and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

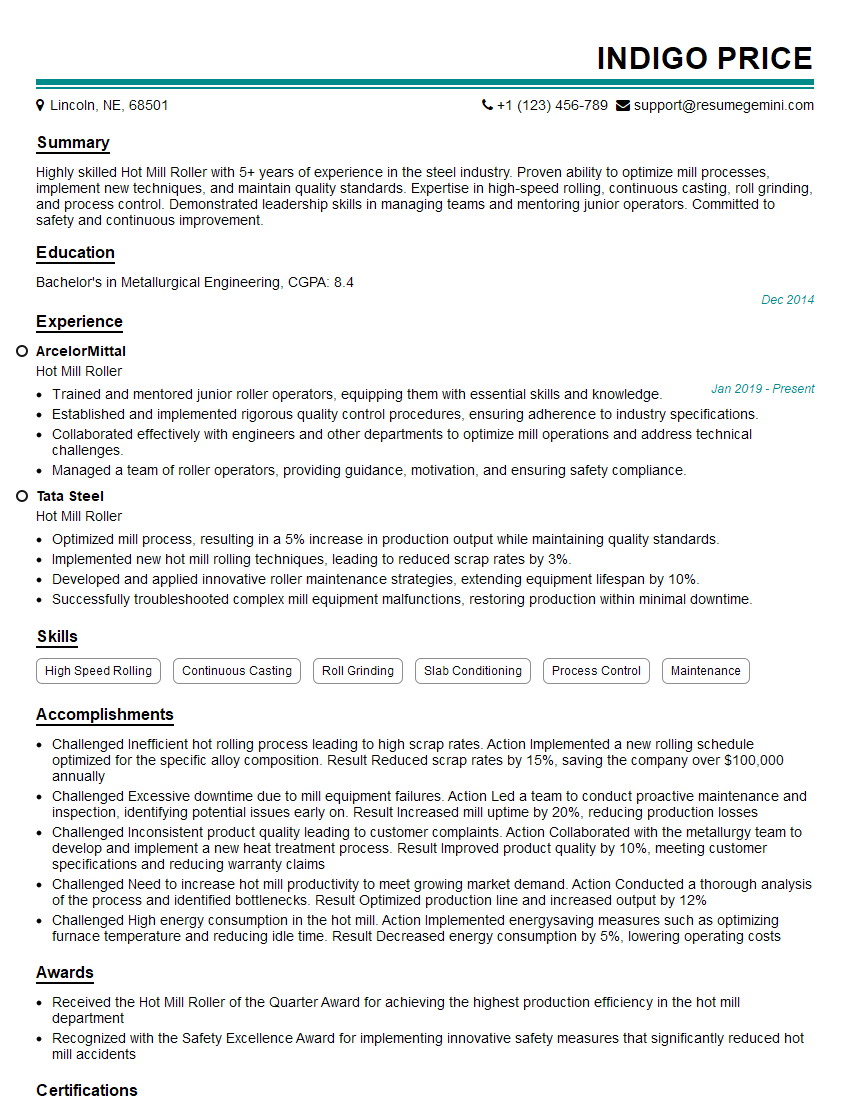

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hot Mill Roller

1. Explain the process of rolling steel in a hot mill?

The process of rolling steel in a hot mill involves several key steps:

- Slab Preparation: Slabs of steel are heated to a high temperature (approximately 1200-1300°C) and then descaled to remove any surface oxides.

- Roughing Mill: The heated slabs pass through a series of roughing mills, which gradually reduce the thickness of the slab and shape it into a bloom or billet.

- Finishing Mill: The bloom or billet is further reduced in thickness and shaped into the desired final product, such as a coil or plate, through a series of finishing mills.

- Cooling and Coiling: After rolling, the hot steel is cooled using water jets or air cooling and then coiled for storage or further processing.

2. What are the different types of hot rolling mills and their applications?

Reversing Mills

- Roll the slab back and forth multiple times

- Used for small orders or specialized products

Continuous Mills

- Roll the slab through a series of stands without reversing

- High production rates and consistent product quality

- Widely used for producing flat products like sheet and plate

Semi-Continuous Mills

- Combine features of reversing and continuous mills

- Provide flexibility and high productivity

3. Describe the role of scale breakers in a hot mill?

Scale breakers are crucial components in a hot mill that perform the following functions:

- Breaking Scale: As the hot steel passes through the rolling process, it forms oxide scales on its surface. Scale breakers use high-pressure water jets to break and remove these scales.

- Descaling: The water jets not only break the scales but also remove them from the steel surface, ensuring a clean and scale-free product.

- Cooling: The water used in scale breakers also helps cool the steel between rolling passes, preventing overheating.

4. What are the common defects found in hot rolled steel and their causes?

Surface Defects

- Scale: Oxide layer formed on steel surface

- Scratches: Caused by mishandling or improper rolling

Internal Defects

- Laminations: Internal voids or cracks

- Inclusions: Non-metallic particles trapped in steel

5. How do you control the thickness and shape of the rolled steel?

Controlling the thickness and shape of rolled steel involves:

- Mill Settings: Adjusting the distance between the rolls

- Roll Profile: Using rolls with specific contours to shape the steel

- Tension Control: Maintaining proper tension on the steel as it passes through the mill

- Temperature Control: Ensuring the steel is at the optimal temperature for rolling

6. What are the safety protocols and procedures you follow in a hot mill environment?

- Wearing proper protective gear (e.g., heat-resistant clothing, gloves)

- Maintaining a safe work area (e.g., clear of obstacles, no loose cables)

- Following lockout/tagout procedures

- Being aware of potential hazards (e.g., high temperatures, moving machinery)

- Reporting any unsafe conditions or incidents

7. How do you troubleshoot and maintain hot mill equipment?

Troubleshooting and maintaining hot mill equipment involves:

- Identifying the problem: Observing symptoms and using diagnostic tools

- Analyzing the cause: Determining the root cause of the issue

- Repairing or replacing: Taking necessary actions to fix or replace faulty components

- Preventive maintenance: Regularly inspecting and servicing equipment to prevent breakdowns

8. Describe the quality control measures you implement in a hot mill?

- Visual Inspection: Examining the steel for surface defects

- Dimensional Checks: Measuring thickness, width, and length

- Mechanical Testing: Conducting tensile, yield, and hardness tests

- Ultrasonic Testing: Identifying internal defects

- Statistical Process Control: Monitoring and analyzing process data to ensure consistent quality

9. How do you optimize the rolling process to minimize defects and improve yield?

- Proper Mill Setup: Ensuring correct roll settings and profile

- Temperature Control: Maintaining optimal rolling temperature

- Tension Control: Optimizing tension throughout the rolling process

- Scale Control: Minimizing scale formation through proper descaling

- Continuous Improvement: Analyzing data and implementing process improvements

10. As a Hot Mill Roller, what are your key responsibilities and how do you contribute to the overall operation of the mill?

- Operating Rolling Mill: Controlling the rolling process and ensuring product quality

- Monitoring Equipment: Observing mill performance and identifying potential issues

- Troubleshooting and Maintenance: Resolving minor issues and coordinating repairs

- Quality Control: Conducting inspections and ensuring compliance with specifications

- Safety Compliance: Adhering to safety protocols and maintaining a safe work environment

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hot Mill Roller.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hot Mill Roller‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Hot Mill Roller plays a crucial role in the production of steel, operating and maintaining sophisticated equipment in the hot mill area of a steel mill. Their primary responsibilities encompass:

1. Operating Rolling Mills

Operate and control rolling mills to reduce the thickness of steel slabs or blooms into desired shapes and dimensions.

2. Monitoring Equipment

Monitor and adjust controls to ensure optimal equipment performance, including temperature, speed, and pressure settings.

3. Quality Control

Inspect and measure steel products to ensure they meet specifications and quality standards.

4. Maintenance and Repair

Perform routine maintenance and repairs on rolling mill equipment to minimize downtime and ensure efficient operations.

Interview Preparation Tips

To effectively prepare for a Hot Mill Roller interview and increase your chances of success, consider the following tips:

1. Research the Company and Role

- Thoroughly research the specific steel mill and industry to gain a comprehensive understanding of their operations and the position you are applying for.

2. Highlight Relevant Skills and Experience

- Emphasize your technical expertise in operating rolling mills and your understanding of steel production processes.

- Highlight your experience in monitoring equipment, performing maintenance, and ensuring quality.

3. Practice Common Interview Questions

- Prepare for common interview questions related to your skills, experience, and motivations for pursuing this role.

- Consider questions such as: “Describe your experience operating rolling mills?” or “How do you ensure the quality of steel products?”

4. Prepare Questions for the Interviewer

- At the end of the interview, be prepared to ask insightful questions that demonstrate your interest in the role and the company.

- For example, you can ask about the specific challenges and opportunities associated with the position or the company’s future plans for hot mill operations.

5. Dress Professionally and Arrive Punctually

- First impressions matter, so dress appropriately and arrive for the interview on time.

6. Be Confident and Enthusiastic

- Approach the interview with confidence and enthusiasm, expressing your passion for the role and the steel industry.

7. Follow Up After the Interview

- Send a thank-you note to the interviewer within 24 hours, expressing your appreciation and reiterating your interest in the position.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Hot Mill Roller, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Hot Mill Roller positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.