Are you gearing up for a career in Hot Mill Tin Roller? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Hot Mill Tin Roller and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

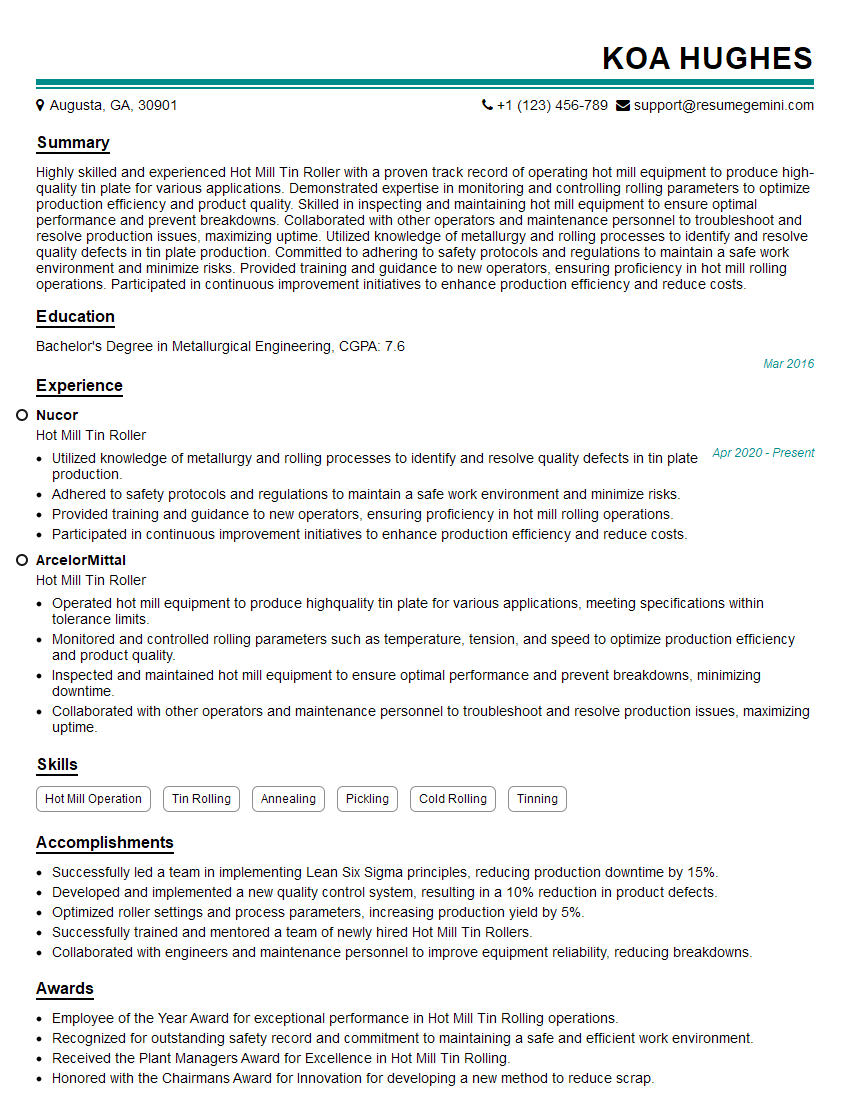

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hot Mill Tin Roller

1. What are the key variables that you control to produce tin plate with the desired properties?

The key variables that I control to produce tin plate with the desired properties are:

- Rolling temperature: The temperature of the steel as it is rolled affects the grain structure and hardness of the final product.

- Rolling speed: The speed at which the steel is rolled affects the thickness and width of the final product.

- Annealing temperature: The temperature at which the steel is annealed affects the hardness and ductility of the final product.

- Tin coating thickness: The thickness of the tin coating affects the corrosion resistance and solderability of the final product.

2. Describe the different types of defects that can occur during tin plate production and the corrective actions that can be taken.

Types of Defects

- Scratches

- Dents

- Corrosion

- Pin holes

Corrective Actions

- Scratches: Inspect the rolls and mill equipment for damage and replace or repair as necessary.

- Dents: Adjust the roll gap or use a different roll profile to reduce or eliminate dents.

- Corrosion: Use a corrosion-resistant coating or increase the tin coating thickness.

- Pin holes: Improve the steelmaking process to reduce the number of inclusions in the steel.

3. What are the different types of tin plate finishes and how are they achieved?

The different types of tin plate finishes and how they are achieved are:

- Bright finish: This finish is achieved by cold rolling the steel to a high degree of brightness.

- Matte finish: This finish is achieved by annealing the steel in a reducing atmosphere, which creates a thin oxide layer on the surface of the steel.

- Spangle finish: This finish is achieved by annealing the steel in an oxidizing atmosphere, which creates a spangled appearance on the surface of the steel.

4. What are the different grades of tin plate and what are their applications?

The different grades of tin plate and their applications are:

- Grade A: This is the highest grade of tin plate and is used for applications where corrosion resistance and solderability are important, such as food packaging.

- Grade B: This is a medium grade of tin plate and is used for applications where corrosion resistance is not as important, such as general packaging.

- Grade C: This is the lowest grade of tin plate and is used for applications where corrosion resistance is not important, such as construction.

5. What are the safety precautions that must be followed when working with tin plate?

The safety precautions that must be followed when working with tin plate are:

- Wear gloves to protect hands from sharp edges.

- Wear safety glasses to protect eyes from flying debris.

- Do not operate machinery without proper training.

- Keep work area clean and free of debris.

- Follow all company safety procedures.

6. What is your experience with the operation and maintenance of tin plate production equipment?

I have over 10 years of experience with the operation and maintenance of tin plate production equipment. I am proficient in all aspects of tin plate production, from raw material preparation to finished product packaging. I am also familiar with the maintenance and repair of all types of tin plate production equipment.

7. What are your strengths and weaknesses as a Hot Mill Tin Roller?

Strengths

- I am a highly skilled and experienced Hot Mill Tin Roller with over 10 years of experience.

- I have a strong understanding of the tin plate production process and the equipment used.

- I am a team player and I am always willing to help others.

- I am a problem solver and I am always looking for ways to improve the production process.

Weaknesses

- I am sometimes too detail-oriented and I can get bogged down in the small details.

- I am not always the best at communicating with others.

8. What are your career goals?

My career goal is to become a Production Manager at a tin plate mill. I believe that my skills and experience would make me a valuable asset to any team.

9. Why are you interested in working at our company?

I am interested in working at your company because I am impressed with your commitment to quality and innovation. I believe that my skills and experience would be a valuable asset to your team.

10. Give me an example of a time when you had to overcome a challenge.

One time, I was working on a tin plate production line when the equipment malfunctioned. I quickly identified the problem and was able to fix it, preventing any downtime. My quick thinking and problem-solving skills saved the company a lot of money.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hot Mill Tin Roller.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hot Mill Tin Roller‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Hot Mill Tin Roller is responsible for operating and maintaining a hot mill that produces tinplate. The primary duties of this role involve:

1. Mill Operation

Operate the hot mill to produce tinplate according to specified quality standards.

- Set up and adjust mill equipment, including rollers, furnaces, and cooling systems.

- Monitor and control mill parameters, such as temperature, tension, and speed.

2. Quality Control

Inspect and test tinplate to ensure it meets quality specifications.

- Conduct physical and chemical tests on tinplate samples.

- Identify and correct any defects in the tinplate.

3. Equipment Maintenance

Perform preventive maintenance and repairs on hot mill equipment.

- Inspect and lubricate machinery.

- Troubleshoot and resolve equipment malfunctions.

4. Safety and Environmental Compliance

Ensure compliance with safety and environmental regulations related to mill operations.

- Follow safety protocols and use appropriate protective equipment.

- Monitor and control emissions and waste generated by the mill.

Interview Tips

Preparing thoroughly for the interview is crucial to making a positive impression and increasing your chances of success. Here are some tips to help you ace your interview:

1. Research the Company and Position

Take the time to learn about the company and the specific responsibilities of a Hot Mill Tin Roller. This will demonstrate your interest in the position and your understanding of the industry.

2. Practice Your Answers

Anticipate common interview questions and prepare your responses in advance. Practice answering questions out loud to improve your delivery and confidence.

3. Highlight Relevant Experience and Skills

Emphasize your experience in hot mill operations, quality control, and equipment maintenance. Showcase your knowledge of tinplate production and your ability to work in a fast-paced manufacturing environment.

4. Showcase Your Technical Abilities

Discuss your understanding of hot mill machinery, control systems, and quality testing techniques. Provide examples of how you have used your technical skills to solve problems and improve mill efficiency.

5. Prepare Questions for the Interviewers

Prepare thoughtful questions to ask the interviewers about the company, the position, and career advancement opportunities. This shows your engagement and interest in the organization.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Hot Mill Tin Roller interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.