Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Hot Mill Worker interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Hot Mill Worker so you can tailor your answers to impress potential employers.

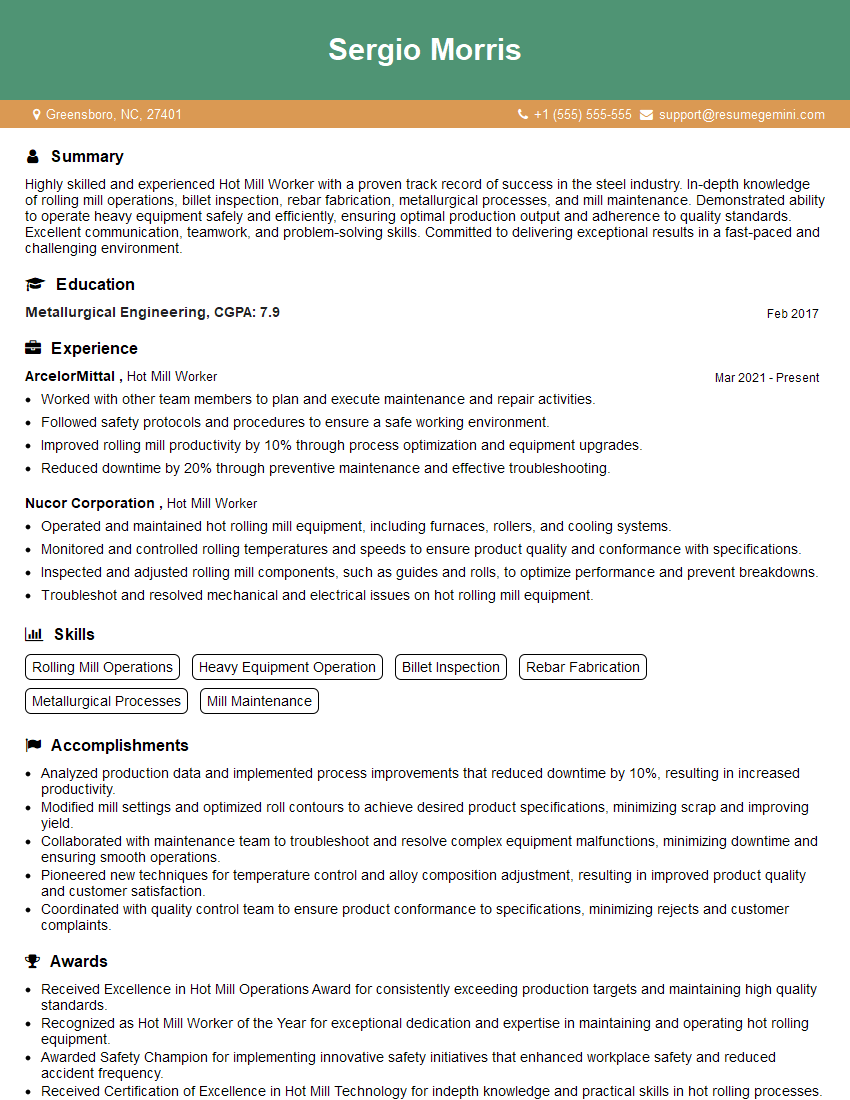

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hot Mill Worker

1. Explain the process of hot rolling?

Hot rolling is a metalworking process that involves passing a metal billet or slab through a series of heated rollers to reduce its thickness and increase its length. The process is carried out at high temperatures, typically above the recrystallization temperature of the metal, which allows the metal to deform plastically without cracking.

- The billet or slab is first heated in a furnace to a temperature that is above its recrystallization temperature.

- The heated billet or slab is then passed through a series of rollers that are arranged in a sequence of decreasing diameters.

- As the billet or slab passes through the rollers, it is reduced in thickness and increased in length.

- The final thickness of the rolled product is controlled by the distance between the rollers.

- The rolled product is then cooled to room temperature.

2. What are the different types of hot rolling mills?

Reversing mills

- Reversing mills are used to roll heavy plates and sections.

- They have two sets of rollers that rotate in opposite directions.

- The billet or slab is passed back and forth between the rollers until it reaches the desired thickness.

Continuous mills

- Continuous mills are used to roll sheet and strip products.

- They have a series of rollers that are arranged in a straight line.

- The billet or slab is passed through the rollers in a continuous process.

Combination mills

- Combination mills are a hybrid of reversing and continuous mills.

- They have two sets of rollers that are arranged in a line, but the rollers can be reversed.

- Combination mills are used to roll a wide range of products.

3. What are the factors that affect the quality of hot rolled products?

The quality of hot rolled products is affected by a number of factors, including:

- The temperature of the billet or slab

- The speed of the rolling process

- The pressure applied to the rollers

- The type of lubricant used

- The cooling rate of the rolled product

4. What are the safety hazards associated with hot rolling?

Hot rolling is a hazardous process, and there are a number of safety hazards that must be considered, including:

- Exposure to high temperatures

- Exposure to molten metal

- Exposure to noise

- Exposure to dust

- Risk of being caught in machinery

5. What are the precautions that must be taken to prevent accidents in a hot rolling mill?

There are a number of precautions that must be taken to prevent accidents in a hot rolling mill, including:

- Wearing appropriate personal protective equipment

- Following proper operating procedures

- Keeping the mill clean and free of debris

- Inspecting equipment regularly

- Training employees on safety procedures

6. What are the maintenance procedures that must be followed to keep a hot rolling mill in good working order?

There are a number of maintenance procedures that must be followed to keep a hot rolling mill in good working order, including:

- Inspecting equipment regularly

- Lubricating moving parts

- Replacing worn or damaged parts

- Calibrating equipment

- Performing preventive maintenance tasks

7. What are the troubleshooting procedures that must be followed when problems occur in a hot rolling mill?

There are a number of troubleshooting procedures that must be followed when problems occur in a hot rolling mill, including:

- Identifying the problem

- Determining the cause of the problem

- Taking corrective action

- Verifying that the problem has been solved

- Documenting the problem and the solution

8. What are the quality control procedures that must be followed to ensure that hot rolled products meet customer specifications?

There are a number of quality control procedures that must be followed to ensure that hot rolled products meet customer specifications, including:

- Inspecting raw materials

- Inspecting in-process products

- Inspecting finished products

- Testing products

- Calibrating equipment

9. What are the environmental regulations that must be followed by hot rolling mills?

There are a number of environmental regulations that must be followed by hot rolling mills, including:

- Regulations on air pollution

- Regulations on water pollution

- Regulations on solid waste disposal

- Regulations on noise pollution

- Regulations on energy consumption

10. What are the future trends in hot rolling technology?

There are a number of future trends in hot rolling technology, including:

- The use of new materials

- The development of new processes

- The use of new technologies

- The increasing use of automation

- The increasing focus on sustainability

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hot Mill Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hot Mill Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Hot Mill Workers play a crucial role in the production of steel, operating specialized equipment to shape and process red-hot metal into desired forms.

1. Furnace Operations:

Operate furnaces that heat steel slabs or billets to the required temperatures for rolling operations.

- Monitor and control furnace temperatures, gas flow, and energy consumption

- Ensure efficient furnace operations, minimizing downtime and maximizing productivity

2. Rolling Operations:

Operate rolling mills that reduce the thickness and shape of steel slabs or billets into desired dimensions.

- Set up and adjust rolling mill equipment based on product specifications

- Monitor rolling operations, adjusting parameters to achieve desired quality and tolerances

3. Quality Assurance:

Monitor and inspect the quality of steel products during the rolling process.

- Detect and identify defects or non-conformities in the steel material

- Report any quality issues to supervisors and implement corrective measures

4. Equipment Maintenance:

Perform routine maintenance and repairs on rolling mills and related equipment to ensure smooth operations.

- Inspect, clean, and lubricate equipment as required

- Identify and report any equipment problems or malfunctions

Interview Tips

Preparing for a Hot Mill Worker interview requires thorough knowledge of the job responsibilities and industry practices. Here are some tips to help you ace the interview:

1. Research the Company and Industry:

Understand the company’s operations, products, and industry trends. Research the specific mill or plant you’re applying to, learning about its production processes and equipment.

2. Highlight Relevant Skills and Experience:

Emphasize your experience in furnace operations, rolling mill processes, and quality control. If you have any prior knowledge or training in metallurgy, metalworking, or industrial engineering, mention it prominently.

3. Prepare for Technical Questions:

Anticipate technical questions about rolling mill equipment, furnace operations, and quality assurance procedures. Be ready to discuss your understanding of these concepts and how you’ve applied them in previous roles.

4. Practice Common Interview Questions:

Prepare for common interview questions such as “Tell me about yourself,” “Why are you interested in this position,” and “What are your strengths and weaknesses.” Practice answering these questions concisely and professionally.

5. Show Enthusiasm and Passion:

Convey your passion for the steel industry and your eagerness to learn and contribute to the team. Highlight your interest in the specific role of Hot Mill Worker and explain why you believe you’re a suitable fit.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Hot Mill Worker role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.