Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Hot Oiler position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

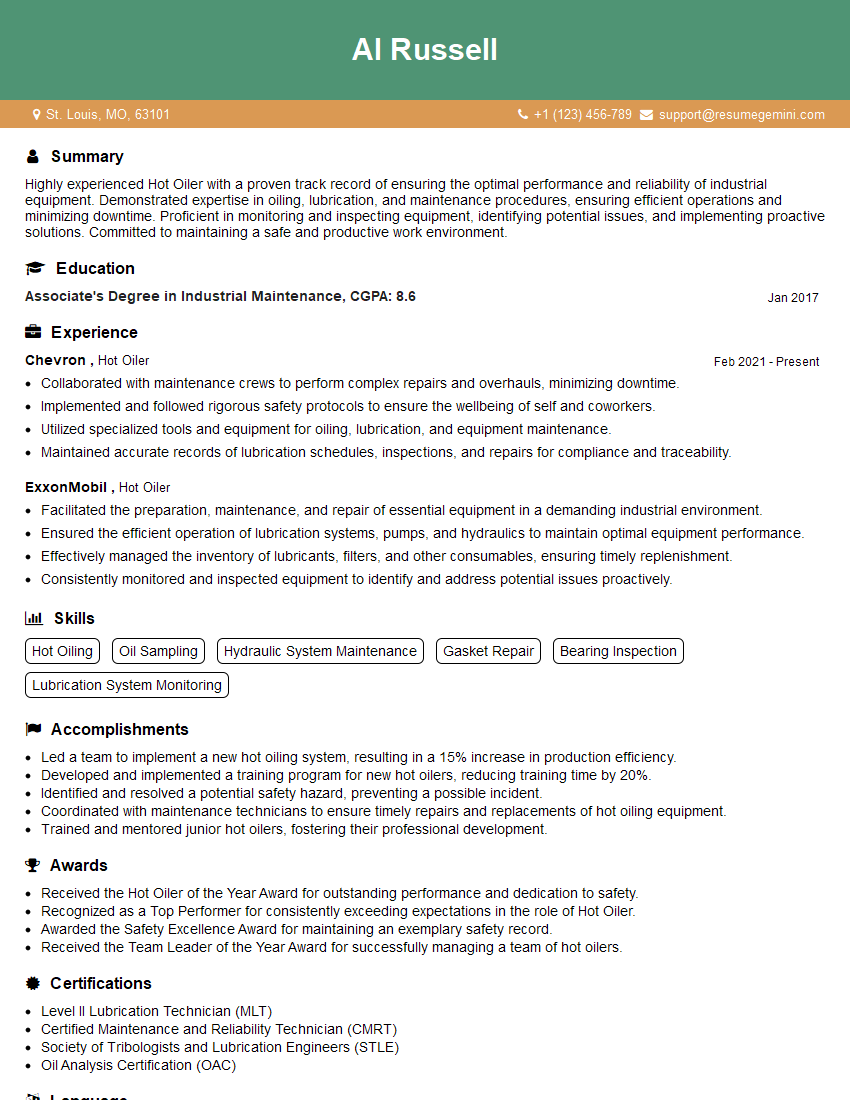

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hot Oiler

1. What are the primary responsibilities of a Hot Oiler?

Answer: As a Hot Oiler, my key responsibilities include:

- Monitor and maintain fluid levels in engines, gearboxes, and other critical components, ensuring optimal performance and preventing overheating

- Lubricate moving parts using oil cups, grease guns, or other lubrication devices to minimize friction and wear

- Inspect and clean oil filters, strainers, and lubrication systems to remove impurities and ensure proper flow rate

- Troubleshoot and resolve lubrication-related issues, identifying and repairing leaks, clogs, or other malfunctions

- Maintain a clean and organized work area, following industry safety protocols

- Assist with other maintenance and repair tasks as required

2. Describe the different types of lubricants and their applications.

Mineral Oils

- Derived from crude oil, mineral oils are commonly used in engines, gearboxes, and hydraulic systems

- They offer good lubrication properties, viscosity stability, and resistance to oxidation

Synthetic Oils

- Engineered from chemical compounds, synthetic oils provide superior performance in high-temperature or high-pressure environments

- They have excellent viscosity stability, low volatility, and extended service intervals

Greases

- Semi-solid lubricants made from a base oil thickened with a gelling agent

- Greases are used in bearings, gears, and other components that require long-term lubrication and protection

3. What is the importance of proper lubrication in machinery maintenance?

Answer: Proper lubrication is crucial for machinery maintenance as it:

- Reduces friction and wear, extending the life of components

- Prevents overheating and seizure, ensuring smooth operation

- Protects against corrosion and premature failure

- Improves energy efficiency by reducing power consumption

- Minimizes downtime and costly repairs

4. How do you assess the condition of used oil and determine if it needs to be replaced?

Answer: I assess the condition of used oil based on several factors:

- Visual Inspection: Checking for discoloration, cloudiness, or the presence of metal shavings or other contaminants

- Oil Analysis: Using laboratory tests to determine the oil’s viscosity, acidity, and contamination levels

- Mileage or Operating Hours: Monitoring the oil’s usage and comparing it to manufacturer recommendations

- Specific Equipment Needs: Considering the type of equipment and its operating conditions

5. What safety precautions should be taken when handling lubricants?

Answer: When handling lubricants, I adhere to the following safety precautions:

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and coveralls

- Handle lubricants in well-ventilated areas to avoid inhalation of fumes

- Store lubricants in designated, labeled containers away from ignition sources

- Dispose of used lubricants properly according to environmental regulations

- Seek medical attention immediately if there is any accidental contact with lubricants

6. Explain the role of viscosity in lubricant selection and its impact on machinery performance.

Answer: Viscosity is a measure of a lubricant’s resistance to flow. It plays a crucial role in lubricant selection as it affects:

- Protection: Higher viscosity lubricants provide thicker films that protect components from wear

- Efficiency: Lower viscosity lubricants flow more easily, reducing friction and improving energy efficiency

- Extreme Temperatures: Viscosity changes with temperature. Selecting the right viscosity ensures optimal performance in different operating conditions

- Equipment Compatibility: Different machines may require different viscosity lubricants to match their design and operating requirements

7. Describe the steps involved in changing the oil and filters on a pump.

Steps:

- Prepare the equipment and gather necessary materials

- Locate the drain plug and place an oil drain pan beneath

- Drain the used oil into the pan, allowing it to cool

- Remove the old oil filter

- Apply a thin layer of clean oil to the gasket of the new oil filter

- Screw on the new oil filter by hand, then tighten it further with a filter wrench

- Replace the drain plug with a new washer, if necessary

- Add the specified amount and type of new oil to the pump

- Run the pump briefly to circulate the oil and check for leaks

- Dispose of the used oil and filter properly

8. How do you troubleshoot common lubrication system problems, such as oil leaks or insufficient pressure?

Troubleshooting Oil Leaks:

- Inspect the system for loose or damaged connections, gaskets, and seals

- Check for cracks or holes in hoses and pipes

- Tighten loose connections or replace damaged components

Troubleshooting Insufficient Pressure:

- Check the oil level and add oil if necessary

- Inspect the oil filter and replace it if clogged

- Examine the pump and ensure it is operating properly

- Check for restrictions in the lubrication system, such as clogged lines or blocked orifices

9. Discuss the importance of preventive maintenance in lubricant management.

Answer: Preventive maintenance is crucial in lubricant management as it:

- Reduces Downtime: Regular maintenance helps detect and address potential lubrication issues before they lead to breakdowns

- Extends Equipment Life: Proper lubrication practices extend the lifespan of machinery by minimizing wear and corrosion

- Improves Efficiency: Well-lubricated equipment operates more efficiently, saving energy and reducing operating costs

- Enhances Safety: Regular maintenance ensures that lubrication systems are in good condition, minimizing the risk of accidents

- Optimizes Lubrication Schedule: Preventive maintenance data helps establish optimal lubrication intervals and avoid over- or under-lubrication

10. Describe your experience with using lubrication equipment, such as grease guns and oil pumps.

Answer: Throughout my career, I have extensive experience in using various lubrication equipment:

- Grease Guns: I am proficient in operating manual and powered grease guns, ensuring accurate and efficient application of grease to bearings and other components

- Oil Pumps: I have used both electric and manual oil pumps to transfer oils to various equipment, including gearboxes, engines, and hydraulic systems

- Oil Dispensers: I am familiar with using oil dispensers to measure and dispense specific amounts of oil, ensuring precise lubrication

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hot Oiler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hot Oiler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Hot Oilers play a crucial role in maintaining the smooth operation of industrial machinery by performing routine maintenance and troubleshooting tasks.

1. Equipment Maintenance and Repairs

Conduct preventive maintenance on machinery, including lubrication, cleaning, and adjustments, to prevent breakdowns.

- Inspect and monitor equipment for signs of wear, damage, or leaks.

- Repair and replace damaged or worn parts.

2. Lubrication and Oil Handling

Ensure proper lubrication of machinery by monitoring oil levels, changing oil filters, and flushing hydraulic systems.

- Maintain and update oil inventory.

- Handle hazardous materials safely and dispose of used oil according to regulations.

3. Equipment Troubleshooting

Identify and resolve equipment malfunctions by conducting diagnostic tests, analyzing error codes, and consulting with mechanics.

- Use diagnostic tools to identify the root cause of equipment problems.

- Communicate findings and recommendations to mechanics.

4. Monitoring and Reporting

Monitor equipment performance and record maintenance activities, including oil changes, repairs, and inspections.

- Maintain detailed maintenance logs.

- Report any safety concerns or potential hazards.

Interview Tips

Preparing thoroughly for a Hot Oiler interview can significantly increase your chances of success. Here are some tips:

1. Research the Company and Position

Familiarize yourself with the company’s industry, products, and culture. Visit their website and read LinkedIn profiles of employees.

- Understand the specific responsibilities of the Hot Oiler position and how they align with your skills and experience.

- Prepare questions about the company and the role to demonstrate your interest and enthusiasm.

2. Highlight Maintenance Experience

Emphasize your experience in maintaining and repairing industrial equipment. Describe your abilities in lubrication, troubleshooting, and preventive maintenance.

- Provide specific examples of equipment you have worked on and the tasks you performed.

- Quantify your accomplishments by stating the number of machines you maintained, the reduction in downtime achieved, or the savings realized through proactive maintenance.

3. Technical Knowledge and Skills

Demonstrate your technical knowledge of machinery, lubrication systems, and diagnostic tools. Discuss your proficiency in using oil analysis, vibration monitoring, and other techniques.

- Mention any certifications or training programs you have completed to enhance your technical skills.

- Explain how you stay updated with the latest industry best practices.

4. Safety and Environmental Awareness

Emphasize your understanding of workplace safety regulations and environmental compliance related to oil handling and disposal.

- Describe your experience in following safety protocols, using personal protective equipment, and handling hazardous materials.

- Explain how you promote environmental sustainability by minimizing waste and adhering to proper oil disposal practices.

5. Communication and Teamwork

Hot Oilers often work in teams and must communicate effectively. Highlight your interpersonal skills and ability to collaborate with mechanics, operators, and other team members.

- Provide examples of times when you successfully resolved equipment issues through effective communication.

- Explain how you stay informed about maintenance schedules and share knowledge with colleagues.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Hot Oiler interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.