Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Hot Plate Plywood Press Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

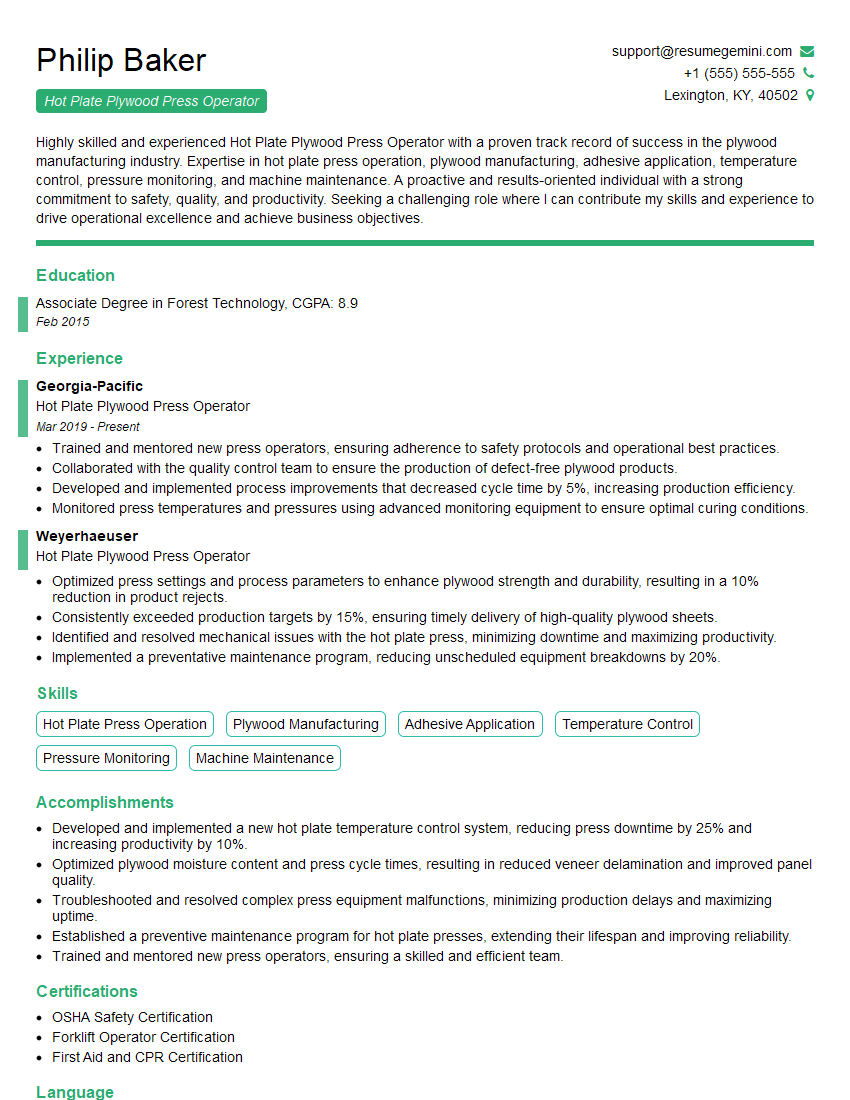

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hot Plate Plywood Press Operator

1. What is the purpose of a hot plate plywood press?

The purpose of a hot plate plywood press is to bond layers of veneer together under heat and pressure to form plywood. The press applies pressure to the veneers, which causes the glue between them to bond. The heat helps to cure the glue and create a strong bond between the layers.

2. What are the main components of a hot plate plywood press?

The main components of a hot plate plywood press are:

- The frame

- The platens

- The hydraulic system

- The control system

The Frame

- The frame is the main structural component of the press. It supports the platens and the hydraulic system.

The Platens

- The platens are the heated plates that apply pressure to the veneers.

The Hydraulic system

- The hydraulic system provides the pressure to the platens.

The control system

- The control system monitors the press and ensures that it operates safely and efficiently.

3. What are the different types of hot plate plywood presses?

There are two main types of hot plate plywood presses:

- Single-opening presses

- Multi-opening presses

Single-opening presses

- Single-opening presses have one platen that opens and closes to load and unload the veneers.

Multi-opening presses

- Multi-opening presses have multiple platens that open and close independently. This allows for faster loading and unloading of the veneers.

4. What are the factors that affect the quality of plywood produced by a hot plate plywood press?

The factors that affect the quality of plywood produced by a hot plate plywood press include:

- The quality of the veneers

- The temperature of the platens

- The pressure applied to the veneers

- The dwell time

- The moisture content of the veneers

5. What are the safety precautions that must be taken when operating a hot plate plywood press?

The safety precautions that must be taken when operating a hot plate plywood press include:

- Wearing appropriate personal protective equipment

- Keeping the press area clean and free of debris

- Never operating the press with the guards removed

- Following the manufacturer’s instructions for operating the press

6. What are the maintenance requirements for a hot plate plywood press?

The maintenance requirements for a hot plate plywood press include:

- Regularly cleaning the press

- Inspecting the press for wear and tear

- Lubricating the moving parts

- Calibrating the press

7. What are the troubleshooting tips for a hot plate plywood press?

The troubleshooting tips for a hot plate plywood press include:

- Checking the power supply

- Checking the hydraulic fluid level

- Checking the temperature of the platens

- Checking the pressure applied to the veneers

- Checking the dwell time

- Checking the moisture content of the veneers

8. What is the role of a hot plate plywood press operator?

The role of a hot plate plywood press operator is to operate and maintain the hot plate plywood press. The operator is responsible for:

- Loading and unloading the veneers

- Setting the temperature of the platens

- Applying pressure to the veneers

- Setting the dwell time

- Monitoring the press

- Performing maintenance on the press

- Troubleshooting problems with the press

9. What are the skills and qualifications required to be a hot plate plywood press operator?

The skills and qualifications required to be a hot plate plywood press operator include:

- Experience in operating a hot plate plywood press

- Knowledge of the principles of plywood manufacturing

- Ability to read and follow instructions

- Ability to work independently and as part of a team

- Physical strength and stamina

10. What is the career path for a hot plate plywood press operator?

The career path for a hot plate plywood press operator can include:

- Promotion to supervisor

- Promotion to production manager

- Promotion to plant manager

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hot Plate Plywood Press Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hot Plate Plywood Press Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Hot Plate Plywood Press Operators play a vital role in the production of plywood, a widely used material in construction and furniture making. They oversee the operation of hot plate presses, ensuring that the plywood meets quality standards and production targets.

1. Plywood Production

Operate hot plate plywood presses to bond layers of wood veneer together with adhesives, forming plywood panels.

- Monitor press temperature, pressure, and cycle time to ensure proper bonding.

- Unload pressed plywood panels and inspect for defects.

2. Machine Maintenance

Perform routine maintenance and troubleshooting on hot plate presses, including cleaning, lubrication, and minor repairs.

- Identify and resolve mechanical or electrical issues to minimize downtime.

- Keep a maintenance log to record inspections, repairs, and any abnormalities observed.

3. Quality Control

Inspect plywood panels for defects, such as voids, splits, and uneven thickness.

- Grade and sort plywood panels based on quality and specifications.

- Maintain accurate records of inspection results and any corrective actions taken.

4. Safety Compliance

Adhere to all safety regulations and guidelines related to the operation of hot plate presses and the handling of hazardous materials.

- Wear appropriate personal protective equipment (PPE) and follow safe work practices.

- Report any potential safety hazards or incidents promptly.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some essential tips to help you ace your interview for a Hot Plate Plywood Press Operator position:

1. Research the Company and Industry

Familiarize yourself with the company’s history, products, and industry trends. This knowledge will demonstrate your interest in the role and the company.

- Visit the company website and LinkedIn page.

- Read industry news and articles to stay informed about current developments.

2. Practice Answering Common Interview Questions

Anticipate potential interview questions and prepare concise, well-structured answers. Practice delivering your responses clearly and confidently.

- Review the key job responsibilities and develop examples of your relevant skills and experiences.

- Consider questions about safety procedures, troubleshooting techniques, and quality control measures.

3. Highlight Your Skills and Experience

Emphasize your technical abilities, such as press operation, maintenance, and quality inspection. Quantify your accomplishments with specific metrics whenever possible.

- Describe your experience with different types of hot plate presses and the production volumes you have achieved.

- Provide examples of how you have successfully resolved press malfunctions and maintained equipment.

4. Showcase Your Safety Mindset

Stress the importance you place on safety in the workplace. Discuss your understanding of safety protocols and your commitment to following them.

- Highlight your knowledge of industry safety standards and your experience in identifying and mitigating risks.

- Explain how you prioritize safety in your daily work and encourage others to do the same.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Hot Plate Plywood Press Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Hot Plate Plywood Press Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.