Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Hot Roller interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Hot Roller so you can tailor your answers to impress potential employers.

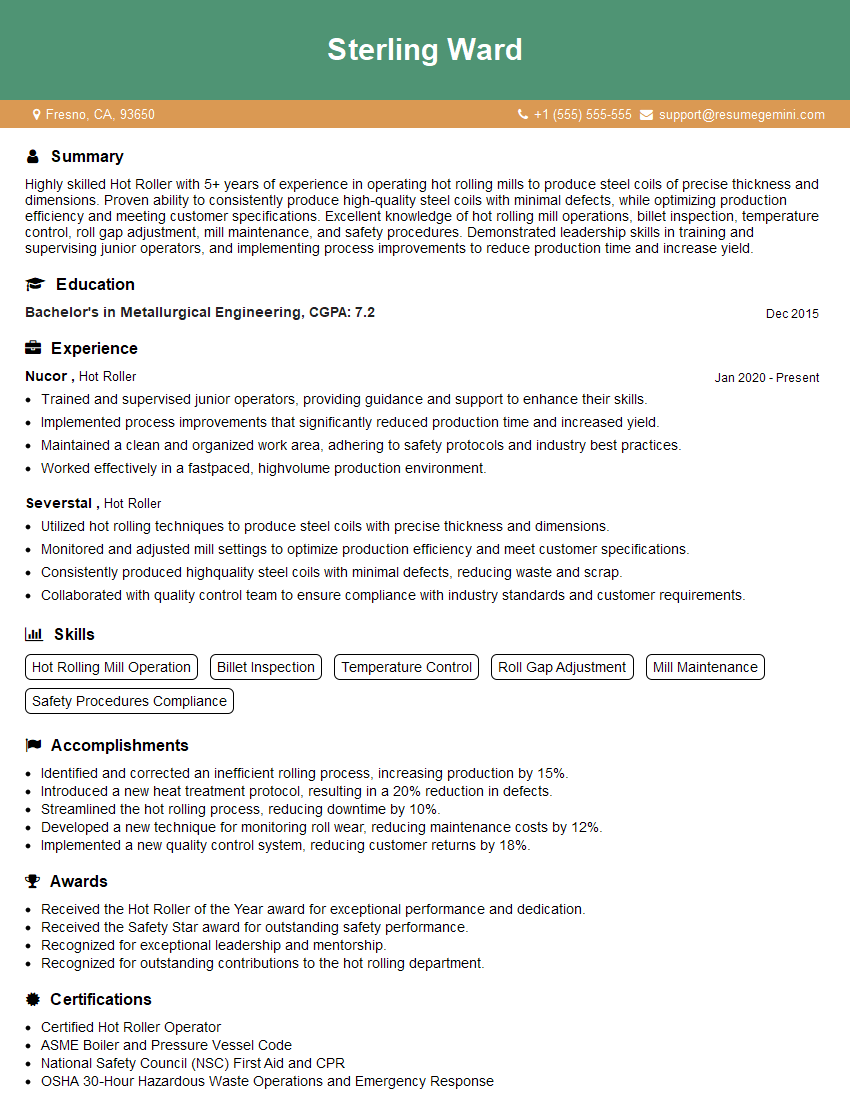

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hot Roller

1. Explain the process of hot rolling?

Hot rolling is a metalworking process where metal is passed through a series of rollers at high temperatures. This process reduces the thickness of the metal and increases its strength.

- The metal is heated to a temperature above its recrystallization temperature.

- The metal is passed through a series of rollers, which reduce its thickness and increase its length.

- The metal is cooled and coiled.

2. What are the different types of hot rolling mills?

There are two main types of hot rolling mills: reversing mills and continuous mills.

Reversing mills

- The metal is passed through the rollers in one direction, then reversed and passed through the rollers in the opposite direction.

- This process is repeated until the desired thickness is achieved.

Continuous mills

- The metal is passed through the rollers in a continuous process.

- This process is more efficient than reversing mills, but it requires more sophisticated equipment.

3. What are the advantages of hot rolling?

- Hot rolling can produce metal with a higher strength-to-weight ratio than cold rolling.

- Hot rolling can produce metal with a more uniform thickness than cold rolling.

- Hot rolling is a more efficient process than cold rolling.

4. What are the disadvantages of hot rolling?

- Hot rolling can produce metal with a rougher surface than cold rolling.

- Hot rolling can produce metal with a lower dimensional accuracy than cold rolling.

- Hot rolling can produce metal with a higher residual stress than cold rolling.

5. What are the applications of hot rolled metal?

- Hot rolled metal is used in a wide variety of applications, including:

- Construction

- Automotive

- Shipbuilding

- Railroad

6. What are the safety considerations for hot rolling?

- Hot rolling is a hazardous process, and it is important to take the following safety precautions:

- Wear appropriate personal protective equipment, including gloves, safety glasses, and a hard hat.

- Be aware of the location of all hot surfaces and avoid contact with them.

- Do not enter the rolling area without authorization.

- Follow all safety procedures and instructions.

7. What are the maintenance requirements for hot rolling mills?

- Hot rolling mills require regular maintenance to ensure safe and efficient operation.

- Some of the most common maintenance tasks include:

- Lubricating the bearings

- Inspecting the rollers for wear and tear

- Replacing worn or damaged parts

8. What are the troubleshooting procedures for hot rolling mills?

- If a hot rolling mill is not operating properly, it is important to follow the following troubleshooting procedures:

- Check the power supply to the mill.

- Inspect the rollers for wear and tear.

- Check the lubrication system.

- Contact the manufacturer for assistance.

9. What are the future trends in hot rolling?

- The future of hot rolling is bright, with a number of new technologies and innovations emerging.

- Some of the most promising trends include:

- The use of advanced materials, such as high-strength steels and aluminum alloys.

- The development of new rolling processes, such as tandem rolling and cross-rolling.

- The use of computer-aided design (CAD) and computer-aided manufacturing (CAM) to improve the efficiency and accuracy of the rolling process.

10. What are the challenges facing the hot rolling industry?

- The hot rolling industry is facing a number of challenges, including:

- The increasing cost of raw materials.

- The growing demand for high-quality steel products.

- The need to reduce energy consumption.

- The need to meet environmental regulations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hot Roller.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hot Roller‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Hot Rollers are responsible for operating hot rolling mills to shape and form metal. They play a crucial role in manufacturing various metal products, including steel sheets, rods, and plates. Key responsibilities of a Hot Roller include:

1. Operating and Monitoring Hot Rolling Mills

Hot Rollers operate and monitor hot rolling mills, ensuring they run smoothly and efficiently. They adjust mill settings, such as temperature, speed, and pressure, to produce metal products with desired dimensions and specifications.

- Adjusting mill settings to control temperature, speed, and pressure

- Monitoring mill performance and making necessary adjustments

- Ensuring the safe and efficient operation of the hot rolling mill

2. Shaping and Forming Metal

Hot Rollers use hot rolling mills to shape and form metal into various products. They manipulate the metal using rollers to achieve the desired thickness, width, and shape.

- Passing metal through rollers to reduce its thickness

- Adjusting roller positions to control the width and shape of the metal

- Inspecting the shaped metal for defects and imperfections

3. Maintaining Equipment and Tools

Hot Rollers are responsible for maintaining the hot rolling mills and associated equipment. They perform regular inspections, lubricate components, and replace worn-out parts to ensure optimal performance.

- Inspecting and lubricating mill components

- Replacing worn-out parts and performing repairs

- Keeping tools and equipment clean and organized

4. Complying with Safety Protocols

Hot Rollers must adhere to strict safety protocols to minimize risks associated with working with heavy machinery and hot metal. They wear protective gear, follow established procedures, and report any hazards or potential issues.

- Wearing appropriate safety gear, such as hard hats and safety glasses

- Following established operating procedures and safety guidelines

- Reporting any potential hazards or unsafe conditions

Interview Tips

To ace your interview for a Hot Roller position, consider the following tips:

1. Research the Company and Industry

Familiarize yourself with the company’s history, products, and industry trends. This demonstrates your interest and enthusiasm for the role.

- Visit the company’s website and social media pages

- Read industry publications and articles

- Learn about the company’s competitors and market position

2. Highlight Relevant Experience and Skills

Emphasize your experience in operating hot rolling mills or similar machinery. Quantify your accomplishments whenever possible, using specific numbers and metrics to demonstrate your impact.

- Describe your previous responsibilities in detail

- Quantify your accomplishments, such as the number of tons of metal produced or the percentage of production increase

- Showcase your technical habilidades, such as your understanding of metallurgy and mechanical principles

3. Showcase Safety and Quality Consciousness

Hot Rollers must prioritize safety and quality. Highlight your commitment to following safety protocols and maintaining high standards in your work.

- Describe your experience with safety procedures and equipment inspections

- Explain how you ensure the quality of the metal products produced

- Discuss your attention to detail and commitment to accuracy

4. Prepare for Common Interview Questions

Research common interview questions for hot rolling positions and practice your answers. This will help you feel confident and articulate during the interview.

- Tell me about your experience operating hot rolling mills

- How do you ensure the quality of the metal products produced?

- Describe your safety procedures and how you prioritize safety in the workplace

5. Ask Thoughtful Questions

At the end of the interview, ask thoughtful questions that demonstrate your interest in the role and the company. This shows that you’re engaged and eager to learn more.

- What are the company’s growth plans and industry outlook?

- Can you describe the opportunities for career advancement within the organization?

- What makes this company a great place to work?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Hot Roller interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!