Feeling lost in a sea of interview questions? Landed that dream interview for Hot Saw Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Hot Saw Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

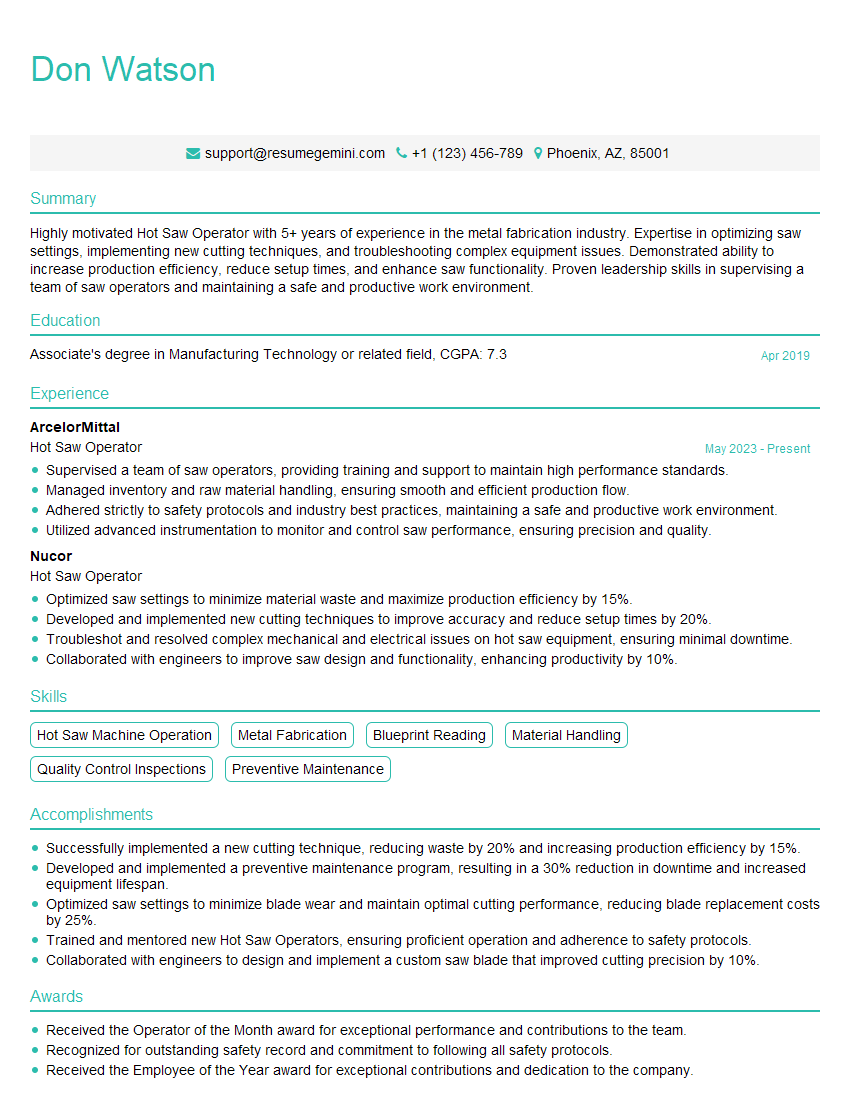

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hot Saw Operator

1. What are the key responsibilities of a Hot Saw Operator?

The key responsibilities of a Hot Saw Operator include:

- Operating and maintaining hot saw equipment to cut metal to specified lengths and dimensions

- Inspecting raw materials and finished products to ensure quality standards are met

- Monitoring production processes and making necessary adjustments to optimize efficiency

- Troubleshooting and resolving equipment malfunctions to minimize downtime

- Adhering to safety protocols and maintaining a clean and organized work environment

2. Describe the different types of hot saws and their applications?

There are several types of hot saws, each with its own specific applications:

Circular Hot Saws

- Used for cutting a wide range of metal shapes and sizes

- Versatile and can be used for both straight and angled cuts

Band Hot Saws

- Designed for cutting thick and heavy metal sections

- Produce a clean and precise cut with minimal burrs

Friction Hot Saws

- Use friction to generate heat and cut through metal

- Suitable for cutting thin and delicate materials

3. What factors should be considered when selecting the appropriate hot saw blade?

When selecting a hot saw blade, the following factors should be considered:

- Material being cut: Different materials require specific blade tooth geometry and sharpness

- Blade diameter and thickness: Larger blades can cut through thicker materials, while thinner blades are more precise

- Tooth count: More teeth result in a finer cut, but a slower cutting speed

- Blade material: Blades can be made from various materials, such as high-speed steel (HSS) or carbide, depending on the application

- Cooling method: Some blades require lubrication or cooling to prevent overheating

4. How do you ensure the accuracy and precision of hot saw cuts?

To ensure the accuracy and precision of hot saw cuts, the following steps should be taken:

- Proper saw maintenance: Regularly inspect and calibrate the saw to maintain its accuracy

- Blade selection: Choose the correct blade based on the material and cutting requirements

- Workpiece preparation: Secure the workpiece firmly to prevent movement during cutting

- Cutting technique: Use a steady and controlled motion when cutting to avoid отклонения

- Measurement and verification: Use measuring tools to verify the accuracy of the cut before moving on

5. What safety precautions should be taken when operating a hot saw?

When operating a hot saw, it is crucial to adhere to the following safety precautions:

- Wear appropriate PPE: Always wear safety glasses, gloves, and ear protection

- Maintain a clean work area: Clear away any debris or flammable materials to prevent accidents

- Secure the workpiece: Ensure that the workpiece is firmly clamped or held to prevent it from moving during cutting

- Inspect the blade: Before each use, inspect the blade for any damage or wear

- Use caution when handling hot metal: Wear heat-resistant gloves and use tongs to handle hot metal pieces

- Follow proper operating procedures: Always follow the manufacturer’s instructions and established safety protocols

6. How do you troubleshoot common hot saw problems?

Common hot saw problems and their troubleshooting steps include:

Blade Breakage

- Check for improper blade selection or excessive cutting force

- Inspect the saw for misalignment or vibration

Poor Cut Quality

- Examine the blade for dullness or damage

- Adjust the cutting speed or feed rate

- Verify that the workpiece is securely held

Equipment Malfunctions

- Check for electrical or mechanical issues

- Consult the manufacturer’s manual for specific troubleshooting steps

7. What techniques can be used to optimize hot saw performance?

To optimize hot saw performance, the following techniques can be employed:

- Blade maintenance: Regularly sharpen or replace blades to maintain optimal cutting efficiency

- Proper lubrication: Ensure that the saw is properly lubricated to reduce friction and wear

- Optimized cutting parameters: Adjust cutting speed and feed rate based on the material and blade specifications

- Workpiece preparation: Clean and deburr the workpiece to improve cut quality

- Preventive maintenance: Regularly inspect and service the saw to prevent breakdowns

8. How do you handle scrap metal generated during hot sawing?

Scrap metal generated during hot sawing should be handled responsibly and in accordance with environmental regulations:

- Segregate scrap metal: Separate ferrous and non-ferrous scrap for recycling purposes

- Store scrap safely: Keep scrap metal in designated containers to prevent accidents

- Recycle scrap metal: Partner with recycling companies to ensure proper disposal and environmental sustainability

9. What is the importance of preventive maintenance for hot saws?

Preventive maintenance for hot saws is crucial for the following reasons:

- Increased uptime: Regular maintenance helps prevent breakdowns and keeps the saw running smoothly

- Improved safety: A well-maintained saw reduces the risk of accidents and injuries

- Extended equipment life: Proper maintenance prolongs the lifespan of the saw and its components

- Optimized performance: Preventive maintenance ensures that the saw operates at its optimal efficiency

- Reduced operating costs: Regular maintenance can help identify and address potential issues early on, preventing costly repairs

10. How would you contribute to a team in a hot saw operating environment?

In a team environment, I would contribute in the following ways:

- Collaboration: I am a team player and enjoy working with others to achieve common goals

- Communication: I am an effective communicator and can clearly convey information to team members

- Problem-solving: I am a quick learner and can work independently or as part of a team to resolve issues

- Safety: I am committed to maintaining a safe work environment and adhering to all safety protocols

- Continuous improvement: I am eager to learn and grow, and I am always looking for ways to improve my skills and contribute to the team’s success

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hot Saw Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hot Saw Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Hot Saw Operators play a crucial role in the manufacturing process by operating hot saws to cut and shape metal bars, rods, and other materials.

1. Saw Operation and Maintenance

The primary responsibility of a Hot Saw Operator is to operate and maintain the hot saw machine. This involves:

- Loading, positioning, and securing materials onto the saw

- Adjusting and operating saw settings to achieve desired cuts and dimensions

- Monitoring saw operations and making necessary adjustments for optimal performance

- Performing routine maintenance, lubrication, and repairs on the saw

2. Quality Control

Hot Saw Operators are also responsible for ensuring the quality of the cut materials. They:

- Inspect cut materials for defects and adherence to specifications

- Make necessary adjustments to the saw to correct any quality issues

- Maintain quality records and report any deviations or defects

3. Material Handling

Hot Saw Operators handle and transport materials of varying weights and dimensions. Their responsibilities include:

- Unloading and loading materials from conveyors or forklifts

- Positioning materials on the saw table and securing them safely

- Moving cut materials from the saw to designated areas

4. Safety and Compliance

Hot Saw Operators prioritize safety and compliance in their work. They:

- Follow established safety procedures when operating the saw

- Wear appropriate personal protective equipment (PPE)

- Maintain a clean and organized work area

Interview Tips

To ace an interview for a Hot Saw Operator position, candidates should:

1. Research the Company and Role

– Learn about the company’s industry, products, and culture.

– Thoroughly review the job description and identify the key skills and responsibilities.

2. Highlight Relevant Experience

– Quantify your experience in operating hot saw machines and handling metal materials.

– Emphasize your ability to achieve quality cuts and maintain high production standards.

3. Demonstrate Safety Awareness

– Discuss your understanding of safety protocols in a manufacturing environment.

– Highlight your experience in working with PPE and maintaining a safe work area.

4. Prepare for Technical Questions

– Study basic saw operation principles, such as blade selection, feed rates, and cutting angles.

– Be prepared to discuss saw maintenance and troubleshooting procedures.

5. Ask Relevant Questions

– Inquire about the company’s production processes, quality control measures, and safety initiatives.

– Ask about opportunities for professional development and career growth.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Hot Saw Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!