Feeling lost in a sea of interview questions? Landed that dream interview for Hot Stamp Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Hot Stamp Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

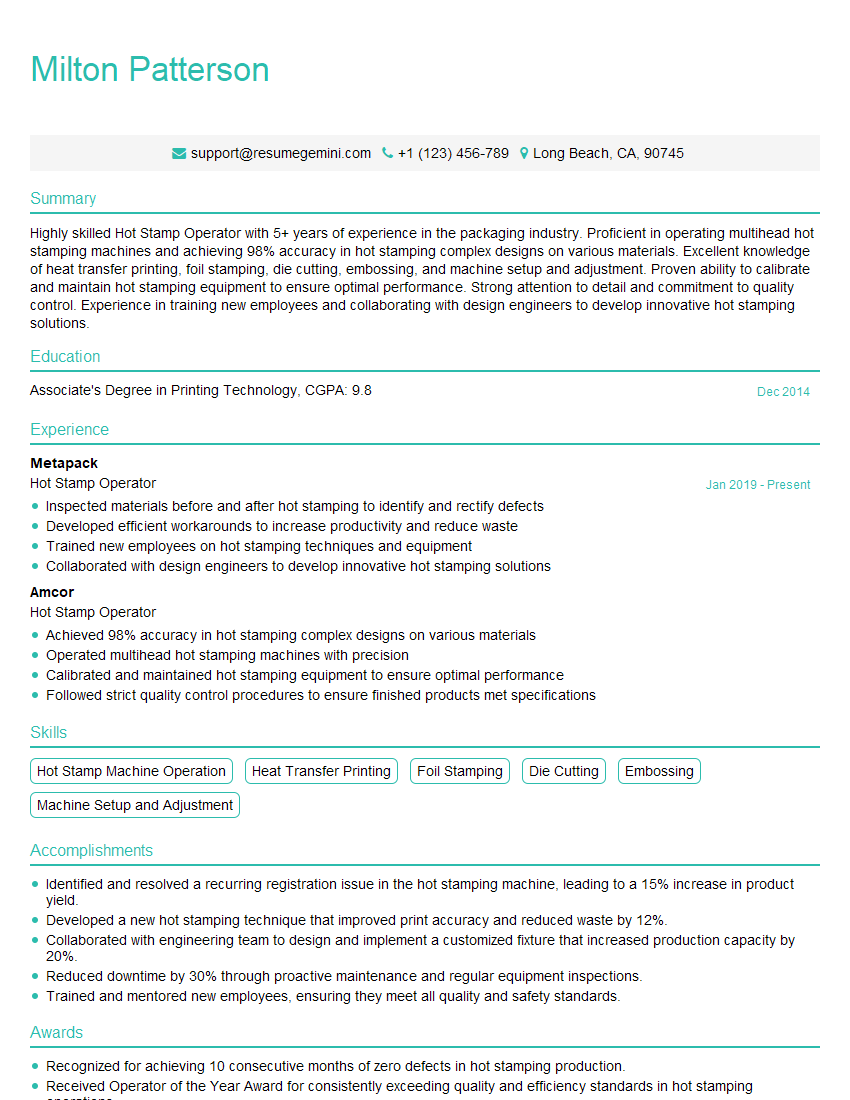

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hot Stamp Operator

1. Explain the process of hot stamping?

Hot stamping is a process of transferring a metallic or pigmented foil onto a surface using heat and pressure. The foil is heated to a high temperature and then pressed onto the surface, causing it to adhere to the substrate. The foil can be any color or design, and it can be used to create a variety of effects, such as lettering, logos, or decorative patterns.

- The process begins with preparing the surface by cleaning and removing any oils or contaminants.

- The foil is then placed on the surface and a heated die is pressed onto it.

- The heat and pressure cause the foil to melt and adhere to the surface.

- The die is then removed and the foil is allowed to cool.

2. What are the different types of hot stamping machines?

Manual

- Manually operated hot stamping machines are the most basic type of machine.

- They are typically used for small production runs or for applications where precision is not critical.

Semi-automatic

- Semi-automatic hot stamping machines are more advanced than manual machines.

- They are capable of feeding the foil and applying the heat and pressure automatically.

- This makes them more efficient and productive than manual machines.

Automatic

- Automatic hot stamping machines are the most advanced type of machine,

- They are capable of performing the entire hot stamping process automatically,

- Including feeding the foil, applying the heat and pressure, and removing the die.

- This makes them the most efficient and productive type of machine.

3. What are the different types of foils used in hot stamping?

- Metallic foils

- Pigmented foils

- Clear foils

- Holographic foils

- Specialty foils

4. What are the factors that affect the quality of a hot stamped image?

- The type of foil

- The temperature of the die

- The pressure applied

- The dwell time

- The surface of the substrate

5. What are some of the common problems that can occur during hot stamping?

- Foil tearing

- Foil blistering

- Foil smudging

- Die sticking

- Poor adhesion

6. How do you troubleshoot hot stamping problems?

- If the foil is tearing, it may be necessary to increase the temperature of the die or decrease the pressure.

- If the foil is blistering, it may be necessary to decrease the temperature of the die or increase the dwell time.

- If the foil is smudging, it may be necessary to clean the die or the surface of the substrate.

- If the die is sticking, it may be necessary to lubricate the die.

- If the adhesion is poor, it may be necessary to use a different type of foil or to increase the pressure.

7. What are the safety precautions that must be taken when operating a hot stamping machine?

- Wear appropriate safety gear, including gloves, safety glasses, and a lab coat.

- Keep the work area clean and free of debris.

- Do not operate the machine if it is damaged or malfunctioning.

- Allow the machine to cool down before performing any maintenance or repairs.

8. What are the maintenance requirements for a hot stamping machine?

- Regularly clean the machine to remove any foil residue or other debris.

- Lubricate the machine according to the manufacturer’s instructions.

- Inspect the machine regularly for any damage or wear and tear.

- Have the machine serviced by a qualified technician on a regular basis.

9. What are the skills and experience required to be a successful hot stamping operator?

- Attention to detail

- Dexterity

- Mechanical aptitude

- Ability to work in a fast-paced environment

- Experience operating hot stamping machines

10. What are the career opportunities for hot stamping operators?

- Hot stamping operators can work in a variety of industries, including manufacturing, packaging, and printing.

- They can advance to positions such as lead operator, supervisor, or manager.

- With additional training, they can also become hot stamping engineers or technicians.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hot Stamp Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hot Stamp Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Hot Stamp Operators play a crucial role in the manufacturing process, ensuring the precise and efficient application of heat stamps to various materials. Their responsibilities encompass a wide range of tasks, including:

1. Machine Setup and Operation

Hot Stamp Operators are responsible for setting up and operating hot stamping machines. This involves preparing equipment, loading and unloading materials, and adjusting machine settings to achieve optimal results.

- Calibrating machines for different materials and stamp designs

- Ensuring proper temperature and pressure settings for accurate stamping

2. Quality Control and Inspection

Hot Stamp Operators are responsible for maintaining the quality of stamped products. They inspect stamped items for defects, ensuring that they meet specifications and customer requirements.

- Identifying and correcting any deviations from quality standards

- Documenting inspection results and maintaining quality records

3. Material Handling

Hot Stamp Operators are involved in handling various materials throughout the stamping process. This includes loading and unloading raw materials, handling stamped products, and maintaining a clean and organized work area.

- Ensuring proper material flow to and from the stamping machine

- Monitoring material inventory and replenishing supplies as needed

4. Equipment Maintenance

Hot Stamp Operators are expected to maintain the stamping equipment in good working condition. This includes performing routine maintenance, troubleshooting problems, and reporting any equipment issues.

- Conducting daily inspections and cleaning of equipment

- Replacing worn or damaged parts and ensuring proper machine operation

Interview Tips

To help you ace your interview for a Hot Stamp Operator position, consider the following tips:

1. Research the Company and Industry

Familiarize yourself with the company’s products, services, and industry trends. This will demonstrate your interest in the role and the organization.

2. Highlight Your Technical Skills

Emphasize your experience with hot stamping machines, material handling, and quality control techniques. Quantify your achievements with specific examples and metrics.

3. Demonstrate Attention to Detail

Hot Stamp Operators must possess a high level of attention to detail. Provide examples that showcase your ability to identify and correct errors, ensuring the accuracy and quality of stamped products.

4. Discuss Problem-Solving Abilities

Interviewers want to know how you handle challenges. Describe situations where you identified and resolved equipment issues, improved processes, or contributed to quality enhancements.

5. Prepare Questions

Asking thoughtful questions at the end of the interview shows your engagement and interest. Prepare questions that seek additional information about the role, company culture, or industry.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Hot Stamp Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!