Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Hot Strip Finisher position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

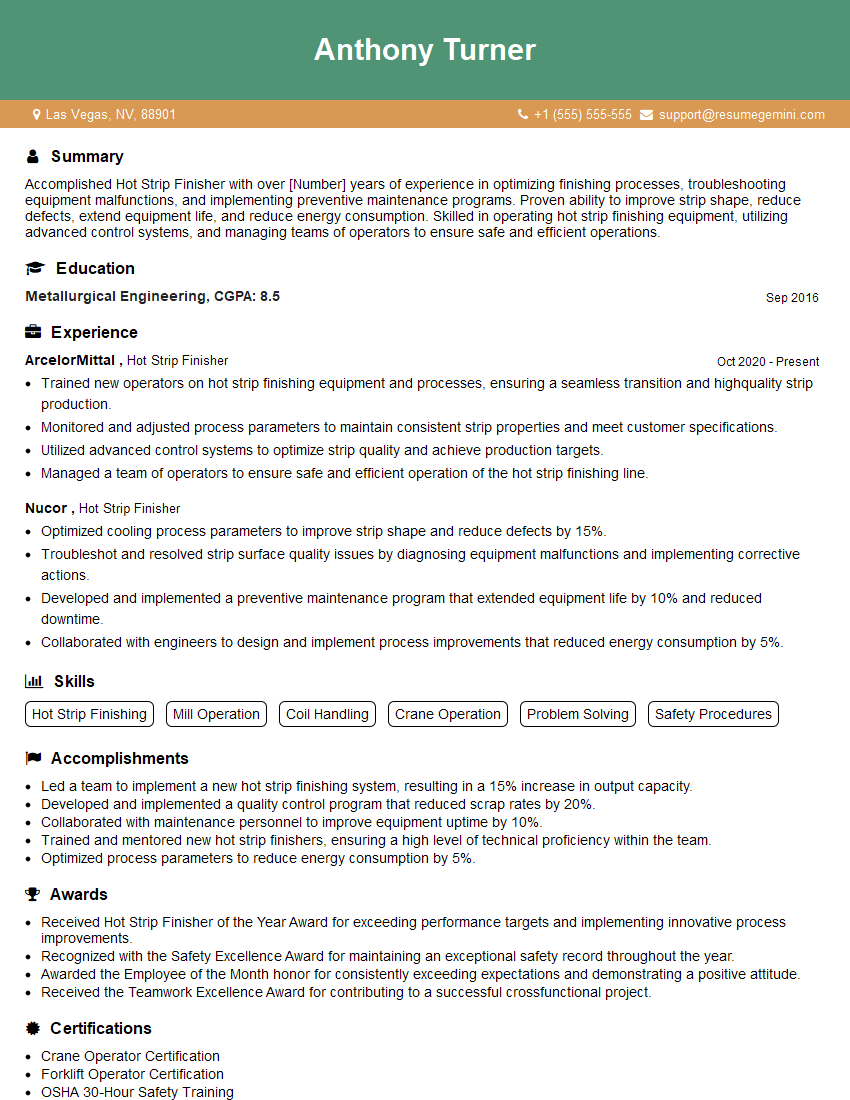

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hot Strip Finisher

1. How do you ensure that the hot strip is flat and has the desired thickness?

- Monitor and adjust the roll gap settings to maintain consistent strip thickness.

- Inspect the strip for flatness using laser leveling systems.

- Utilize crown control to correct for any unevenness in the strip.

2. What are the common defects that can occur during hot strip finishing?

Surface Defects

- Edge cracks

- Centerline cracks

- Scale

Dimensional Defects

- Thickness variation

- Width variation

- Length variation

3. How do you diagnose and resolve electrical faults in the hot strip finishing line?

- Identify the fault using electrical test equipment.

- Trace the circuit to locate the faulty component.

- Repair or replace the faulty component.

- Test the system to ensure the fault has been resolved.

4. Describe the role of cooling and coiling in the hot strip finishing process.

- Control the strip temperature to obtain desired mechanical properties.

- Laminar cooling to ensure uniform cooling and prevent surface defects.

- Coil the strip to prevent damage and facilitate handling and storage.

5. What are the safety protocols that you follow during hot strip finishing operations?

- Wear appropriate protective gear, including heat-resistant clothing and gloves.

- Follow lockout/tagout procedures when performing maintenance.

- Maintain a clean and organized work area.

- Be aware of potential hazards, such as moving machinery and hot surfaces.

6. Discuss the maintenance procedures you perform to ensure the efficiency and reliability of the hot strip finishing line.

- Regular inspection and lubrication of equipment.

- Replacement of worn or damaged components.

- Calibration of sensors and instrumentation.

- Troubleshooting and resolution of mechanical and electrical issues.

7. How do you optimize the hot strip finishing process to improve product quality and reduce production costs?

- Fine-tune process parameters to minimize defects and maximize yield.

- Implement lean manufacturing techniques to reduce waste and improve efficiency.

- Utilize data analysis to identify and address process bottlenecks.

8. Describe the environmental regulations that apply to hot strip finishing operations and how you ensure compliance.

- Air pollution control regulations, such as those related to fugitive dust emissions.

- Water pollution control regulations, such as those governing wastewater discharge.

- Monitor emissions and wastewater discharge to ensure compliance with regulations.

- Implement pollution prevention measures, such as using low-VOC solvents.

9. How do you stay updated on the latest technologies and best practices in hot strip finishing?

- Attend industry conferences and exhibitions.

- Read trade publications and technical journals.

- Network with other professionals in the field.

- Participate in continuing education programs.

10. What are your career aspirations in the field of hot strip finishing?

- Advance my technical knowledge and expertise.

- Contribute to process improvements and innovations.

- Assume a leadership role in the hot strip finishing team.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hot Strip Finisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hot Strip Finisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Hot Strip Finisher is an essential part of the steel manufacturing process, responsible for ensuring the production of high-quality hot rolled steel strips.

1. Production Monitoring

Monitors and controls the hot rolling mill process, ensuring that the steel strips meet the required specifications.

- Adjusts mill settings to optimize production efficiency.

- Inspects the steel strips for defects and takes corrective actions as necessary.

2. Equipment Maintenance

Performs preventive and corrective maintenance on the hot rolling mill equipment, including lubrication, adjustments, and repairs.

- Troubleshoots and identifies equipment malfunctions.

- Recommends and implements improvements to enhance equipment performance.

3. Quality Control

Ensures the quality of the hot rolled steel strips by conducting inspections and testing.

- Performs non-destructive testing, such as ultrasonic and magnetic particle inspection.

- Interprets test results and takes appropriate actions to correct defects.

4. Safety Compliance

Adheres to safety protocols and regulations, ensuring a safe work environment.

- Operates the hot rolling mill equipment safely and efficiently.

- Identifies and mitigates potential hazards in the workplace.

Interview Tips

Preparing thoroughly for an interview as a Hot Strip Finisher can significantly increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and the Position

Familiarize yourself with the company’s website, industry reputation, and the specific requirements of the Hot Strip Finisher role.

- Demonstrate your understanding of the company’s products and processes.

- Tailor your answers to address the key responsibilities and qualifications outlined in the job description.

2. Highlight Your Technical Skills

Emphasize your expertise in hot rolling mill operations, equipment maintenance, and quality control.

- Quantify your accomplishments whenever possible, using specific metrics and results.

- Provide examples of your ability to troubleshoot and solve problems efficiently.

3. Soft Skills

Demonstrate your teamwork, communication, and problem-solving skills.

- Explain how you effectively collaborate with colleagues in a fast-paced environment.

- Describe your approach to resolving conflicts and managing stress under pressure.

4. Prepare Questions for the Interviewer

Asking thoughtful questions shows your interest and engagement.

- Inquire about the company’s growth plans and the challenges facing the industry.

- Ask about the specific responsibilities of the Hot Strip Finisher role within the team.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Hot Strip Finisher, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Hot Strip Finisher positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.