Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Hot-Wire Glass Tube Cutter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

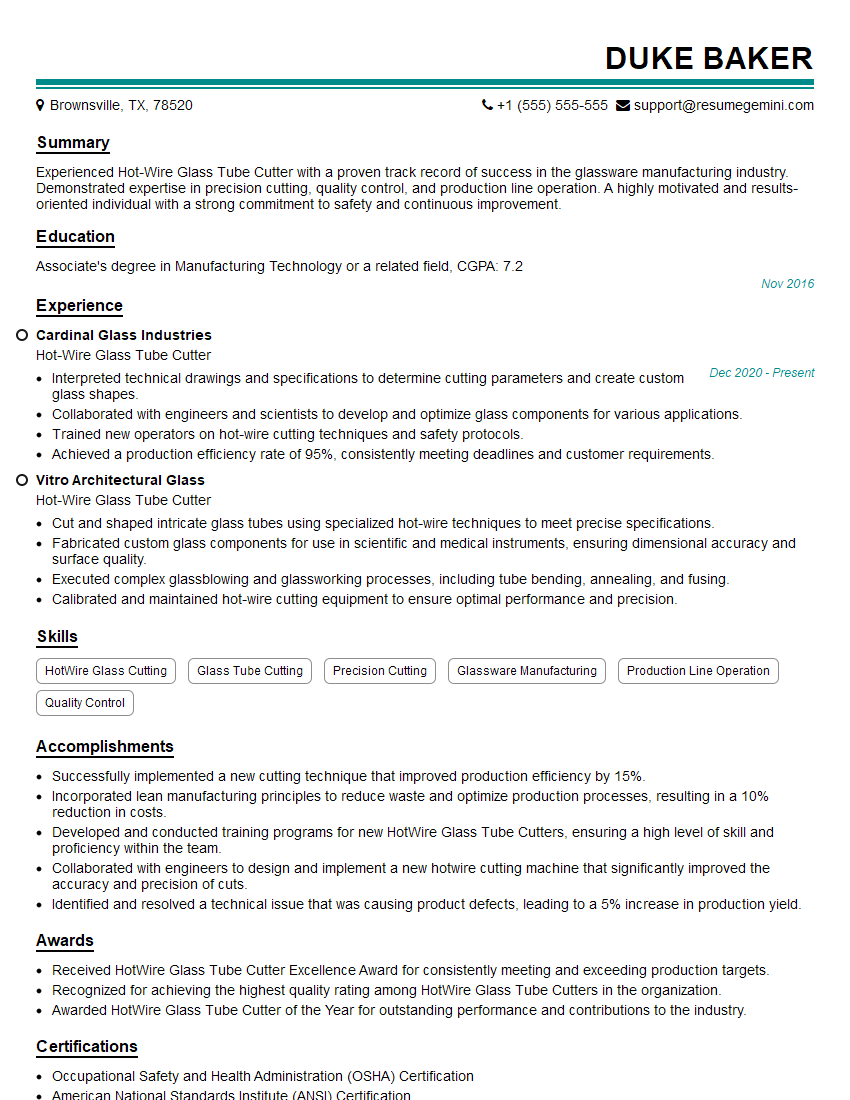

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hot-Wire Glass Tube Cutter

1. Describe the working principle of a hot-wire glass tube cutter.

- The hot-wire glass tube cutter uses a thin, electrically heated wire to cut glass.

- When the wire is brought into contact with the glass, it heats the glass locally, causing it to fracture.

- The wire is typically made of nichrome or platinum, which have high electrical resistance and can withstand high temperatures.

2. What are the key factors that affect the quality of the cut made by a hot-wire glass tube cutter?

- Temperature of the wire: The wire must be hot enough to melt the glass, but not so hot that it vaporizes the glass or causes it to shatter.

- Speed of the wire: The wire must move quickly enough to prevent the glass from cooling and solidifying before it is cut.

- Angle of the wire: The wire must be held at a slight angle to the glass to create a clean, straight cut.

3. What are the different types of glass that can be cut with a hot-wire glass tube cutter?

- Soda-lime glass (the most common type of glass)

- Borosilicate glass (also known as Pyrex)

- Quartz glass

- Sapphire glass

4. What are the safety precautions that must be taken when using a hot-wire glass tube cutter?

- Wear gloves: The wire and the glass can be very hot and can cause burns.

- Wear safety glasses: Glass fragments can fly off during cutting.

- Ventilate the area: Fumes from the glass can be harmful if inhaled.

- Keep the wire away from flammable materials: The wire can ignite flammable materials.

5. What maintenance tasks are required for a hot-wire glass tube cutter?

- Clean the wire: The wire can become coated with glass residue, which can affect its performance.

- Check the electrical connections: Loose connections can cause the wire to overheat.

- Calibrate the machine: The machine must be calibrated regularly to ensure that it is cutting accurately.

6. What are the advantages of using a hot-wire glass tube cutter over other methods of glass cutting?

- Clean, precise cuts: The hot-wire glass tube cutter produces clean, precise cuts with minimal chipping or cracking.

- Fast cutting: The hot-wire glass tube cutter can cut glass quickly and efficiently.

- Versatile: The hot-wire glass tube cutter can be used to cut a variety of glass types and thicknesses.

7. What are the disadvantages of using a hot-wire glass tube cutter?

- Expensive: Hot-wire glass tube cutters can be expensive to purchase and maintain.

- Requires training: Hot-wire glass tube cutters require training to use safely and effectively.

- Not suitable for all types of glass: Hot-wire glass tube cutters cannot be used to cut tempered glass or laminated glass.

8. What is the difference between a hot-wire glass tube cutter and a cold-wire glass tube cutter?

- Hot-wire glass tube cutters: Use a heated wire to cut glass.

- Cold-wire glass tube cutters: Use a cold, diamond-tipped wire to cut glass.

- Hot-wire glass tube cutters are faster and more versatile than cold-wire glass tube cutters, but they can only be used to cut certain types of glass.

9. What are the different applications for a hot-wire glass tube cutter?

- Cutting glass tubes for scientific research

- Cutting glass tubes for medical applications

- Cutting glass tubes for lighting

- Cutting glass tubes for decorative purposes

10. What are the future trends in hot-wire glass tube cutting technology?

- Laser-assisted hot-wire glass tube cutting: Lasers can be used to assist in the cutting process, resulting in faster, more precise cuts.

- Automated hot-wire glass tube cutting: Automated systems can be used to load, cut, and unload glass tubes, increasing efficiency and reducing labor costs.

- Ultrasonic hot-wire glass tube cutting: Ultrasonic vibrations can be used to assist in the cutting process, resulting in cleaner, smoother cuts.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hot-Wire Glass Tube Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hot-Wire Glass Tube Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Hot-Wire Glass Tube Cutters operate specialized machinery in order to cut and shape glass tubes for use in scientific and laboratory applications. The key job responsibilities of a Hot-Wire Glass Tube Cutter include:

1. Operating machinery

Hot-Wire Glass Tube Cutters operate a variety of machinery, including hot-wire saws, flame-working torches, and glass lathes. They use these machines to cut, shape, and finish glass tubes to meet specific requirements.

2. Setting up and calibrating equipment

Hot-Wire Glass Tube Cutters must set up and calibrate the machinery they use in order to ensure that it is operating correctly and producing accurate results. They must also maintain and repair the equipment as needed.

3. Reading and interpreting blueprints and specifications

Hot-Wire Glass Tube Cutters must be able to read and interpret blueprints and specifications in order to understand the requirements of the job. They must also be able to communicate with engineers and other professionals to clarify any questions they may have about the job.

4. Inspecting finished products

Hot-Wire Glass Tube Cutters must inspect the finished products they produce to ensure that they meet the required specifications. They must also be able to identify and correct any defects in the products before they are shipped out to customers.

Interview Tips

Preparing for an interview for a Hot-Wire Glass Tube Cutter position can be daunting, but by following these tips, you can increase your chances of success:

1. Research the company and the position

Before going to an interview, it is important to research the company and the position you are applying for. This will help you to understand the company’s culture and values, as well as the specific requirements of the job. You can find this information on the company’s website, in industry publications, or by talking to people who work for the company.

2. Practice answering common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is helpful to practice answering these questions in advance so that you can deliver your answers confidently and concisely.

3. Be prepared to talk about your experience and skills

The interviewer will want to know about your experience and skills as a Hot-Wire Glass Tube Cutter. Be prepared to talk about your experience operating machinery, setting up and calibrating equipment, reading and interpreting blueprints and specifications, and inspecting finished products.

4. Be enthusiastic and professional

First impressions matter, so it is important to be enthusiastic and professional during your interview. Dress appropriately, arrive on time, and be polite and respectful to the interviewer. By showing that you are interested in the position and that you are a hard worker, you can increase your chances of making a positive impression on the interviewer.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Hot-Wire Glass Tube Cutter interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.