Feeling lost in a sea of interview questions? Landed that dream interview for Huller but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Huller interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

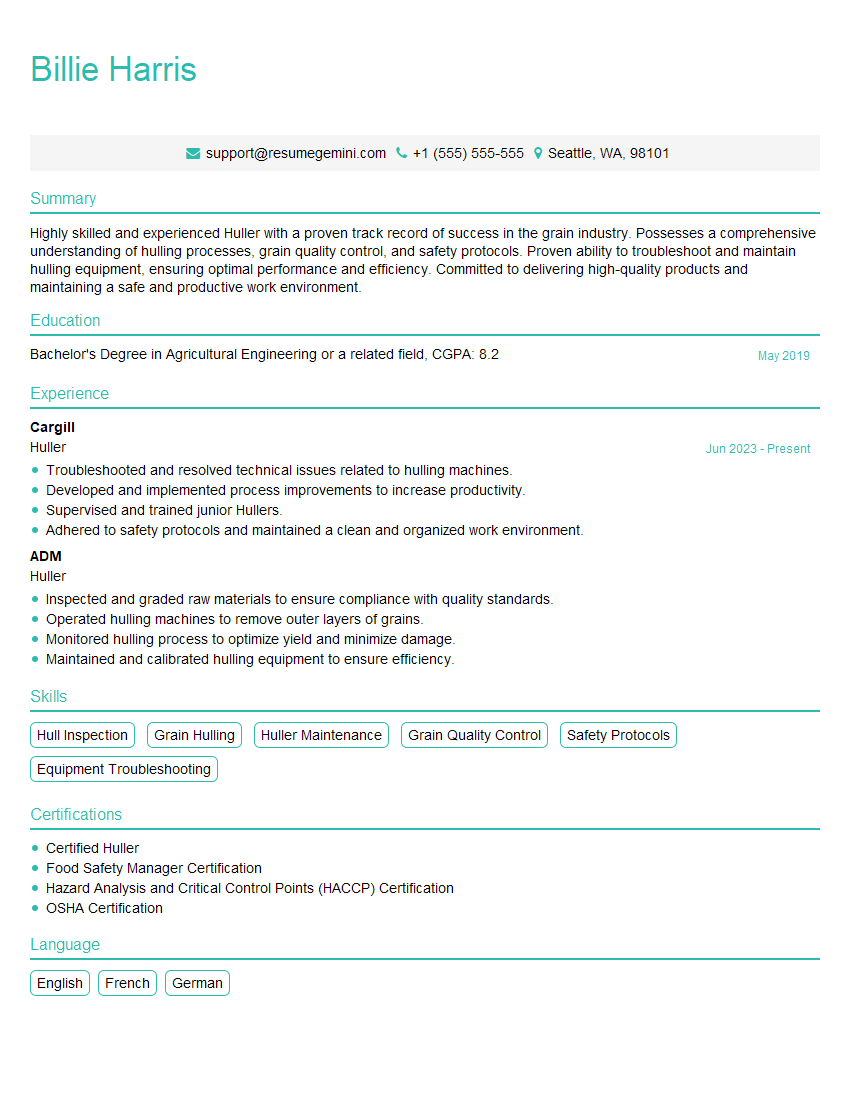

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Huller

1. What are the key responsibilities of a Huller operator?

As a Huller operator, I would be responsible for:

- Operating the hulling machine to remove the hulls from grains and seeds

- Maintaining the machine and ensuring it is in good working condition

- Monitoring the hulling process to ensure the quality of the final product

- Cleaning and sanitizing the machine and work area

2. What experience do you have in operating a hulling machine?

Knowledge of different types of hulling machines

- I have extensive experience in operating a variety of hulling machines, including centrifugal hullers, impact hullers, and abrasive hullers.

- I am familiar with the different types of grains and seeds that can be hulled, and I know how to adjust the machine settings to achieve the desired results.

Experience in troubleshooting and maintaining hulling machines

- I am also experienced in troubleshooting and maintaining hulling machines.

- I can quickly identify and fix common problems, and I am able to perform routine maintenance tasks to keep the machine running smoothly.

3. What are the safety precautions that need to be taken when operating a hulling machine?

When operating a hulling machine, it is important to take the following safety precautions:

- Wear appropriate personal protective equipment, such as safety glasses, gloves, and earplugs.

- Inspect the machine before each use to ensure that it is in good working condition.

- Keep the work area clean and free of debris.

- Never reach into the machine while it is running.

- Shut off the machine and disconnect the power before performing any maintenance or repairs.

4. What are the quality control procedures that need to be followed when hulling grains and seeds?

In order to ensure the quality of the final product, it is important to follow the following quality control procedures when hulling grains and seeds:

- Inspect the grains and seeds before hulling to remove any foreign objects or damaged kernels.

- Set the machine settings to the correct specifications for the type of grain or seed being hulled.

- Monitor the hulling process to ensure that the hulls are being removed evenly and completely.

- Inspect the hulled grains and seeds to remove any remaining hulls or debris.

5. What is the difference between a huller and a dehuller?

- A huller is used to remove the outer shell or hull from grains and seeds, while a dehuller is used to remove the inner bran layer.

- Hullers are typically used for grains such as rice, barley, and oats, while dehullers are used for legumes such as beans, lentils, and peas.

- The process of hulling is typically more aggressive than dehullering, and can result in some loss of the grain or seed’s nutrients.

6. What are the different types of hulling machines?

- Centrifugal hullers use centrifugal force to remove the hulls from grains and seeds.

- Impact hullers use impact force to remove the hulls from grains and seeds.

- Abrasive hullers use abrasive materials to remove the hulls from grains and seeds.

7. What are the factors that affect the efficiency of a hulling machine?

- The type of grain or seed being hulled

- The moisture content of the grain or seed

- The size and shape of the grain or seed

- The speed of the hulling machine

- The settings of the hulling machine

8. What are the common problems that can occur with hulling machines?

- The machine may not be able to remove the hulls from the grains or seeds.

- The machine may damage the grains or seeds.

- The machine may be too noisy.

- The machine may be too slow.

- The machine may be too expensive.

9. What are the maintenance requirements for a hulling machine?

- The machine should be cleaned regularly.

- The machine should be lubricated regularly.

- The machine should be inspected regularly for wear and tear.

- The machine should be repaired or replaced as needed.

10. What are the safety precautions that should be taken when operating a hulling machine?

- The machine should be operated in a safe location.

- The machine should be operated by trained personnel.

- The machine should be equipped with safety guards.

- The machine should be operated in accordance with the manufacturer’s instructions.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Huller.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Huller‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Huller is responsible for operating and maintaining hulling machines or lines to remove the outer hulls from grains, seeds or nuts. Some of the key job responsibilities of a Huller include:

1. Operating and Maintaining Hulling Machines

Hullers are responsible for operating and maintaining hulling machines or lines. This may involve:

- Setting up and adjusting machines to ensure proper operation

- Monitoring machines during operation and making adjustments as necessary

- Performing routine maintenance on machines, such as cleaning and lubricating

- Troubleshooting and repairing machines when problems occur

2. Inspecting and Grading Products

Hullers are also responsible for inspecting and grading products. This may involve:

- Inspecting products for defects, such as broken hulls or foreign objects

- Grading products according to quality standards

- Rejecting products that do not meet quality standards

3. Maintaining a Safe Work Environment

Hullers must also maintain a safe work environment. This may involve:

- Following safety procedures

- Wearing appropriate safety gear

- Keeping work areas clean and organized

- Reporting any hazards to supervisors

4. Other Duties

Hullers may also be required to perform other duties, such as:

- Assisting with the loading and unloading of products

- Cleaning and sanitizing equipment

- Maintaining records of production

Interview Tips

Preparing for an interview can be stressful, but there are a few things you can do to increase your chances of success.

1. Research the company and the position

Take some time to learn about the company you’re applying to and the position you’re interviewing for. This will help you answer questions intelligently and show the interviewer that you’re genuinely interested in the opportunity.

2. Practice your answers to common interview questions

There are a few common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Practice your answers to these questions in advance so that you can deliver them confidently and concisely.

3. Dress appropriately

First impressions matter, so make sure you dress appropriately for your interview. This doesn’t mean you have to wear a suit and tie, but you should dress in clean, pressed clothes that are appropriate for the workplace.

4. Be on time

Punctuality is important for any job interview. Arrive on time for your interview, or even a few minutes early if possible. This shows the interviewer that you’re respectful of their time and that you’re serious about the opportunity.

5. Be confident and enthusiastic

Confidence is key in any interview. Be confident in your abilities and in your qualifications for the position. Show the interviewer that you’re enthusiastic about the opportunity and that you’re eager to learn and grow.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Huller interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!