Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Hydraulic Chair Assembler position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

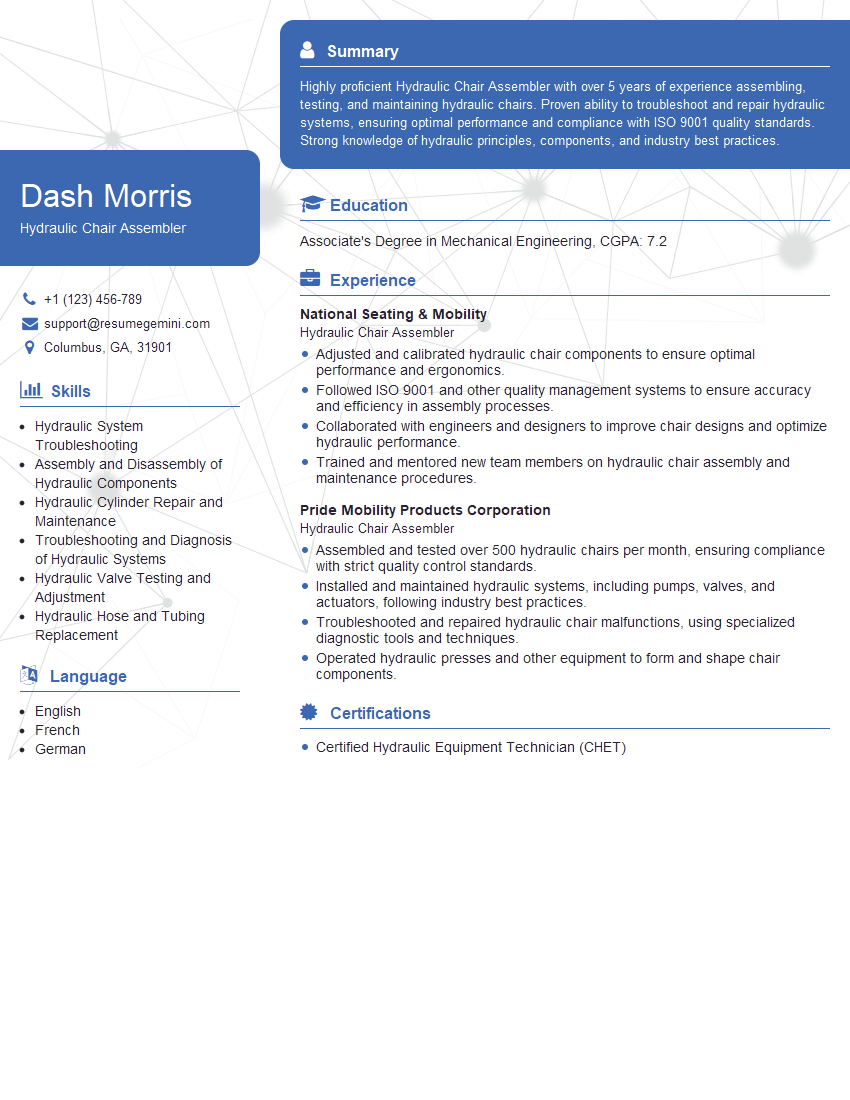

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hydraulic Chair Assembler

1. What are the different types of hydraulic chairs and their uses?

There are various types of hydraulic chairs designed for specific purposes:

- Office chairs: Adjustable height and ergonomic features for comfort and support during prolonged use.

- Medical chairs: Designed for patient care, examination, and other medical procedures, offering height adjustment and positioning options.

- Laboratory chairs: Provide height adjustability and are resistant to chemicals and spills commonly found in laboratory environments.

- Industrial chairs: Robust and durable chairs built to withstand heavy use in industrial settings, such as workshops and factories.

2. What are the key components of a hydraulic chair and their functions?

- Hydraulic cylinder: Provides the lifting force and height adjustment through hydraulic pressure.

- Base and frame: Support the chair and provide stability during use.

- Seat: Provides comfort and support for the user.

- Footrest: Enhances user comfort by providing additional support for the feet.

- Control lever: Allows the user to adjust the chair’s height effortlessly.

3. Explain the principles of hydraulics and their application in hydraulic chairs.

Hydraulics involves using a liquid (usually hydraulic oil) to transmit power and motion:

- Pascal’s Law: Pressure applied to a confined fluid is transmitted equally throughout the fluid.

- Hydraulic chairs utilize this principle: When the control lever is activated, hydraulic oil is pumped into the cylinder, creating pressure.

- The pressure lifts the piston inside the cylinder, raising the seat of the chair.

- Releasing the control lever allows the oil to flow back into the reservoir, lowering the chair.

4. Describe the safety precautions to consider when working with hydraulic chairs.

- Inspect the chair regularly: Check for leaks, loose connections, or any damage that could compromise safety.

- Avoid overloading the chair: Exceeding the chair’s weight capacity can lead to instability and potential accidents.

- Use caution when adjusting the seat: Ensure the chair is stable and the user is properly seated before adjusting the height.

- Keep the work area clean: Spills or debris can create a slippery or hazardous environment.

5. What are the common troubleshooting techniques for hydraulic chairs that are not functioning properly?

- Check the hydraulic fluid level: Low fluid levels can affect the chair’s lifting ability.

- Inspect the hydraulic lines: Leaks or blockages can prevent proper fluid flow.

- Test the control lever: Ensure it is functioning correctly and transmitting commands to the hydraulic system.

- Examine the piston and cylinder: Damage or wear can impact the chair’s performance.

6. Explain the maintenance procedures to prolong the lifespan of hydraulic chairs.

- Regular cleaning: Remove dust, dirt, and debris from the chair’s surface and components.

- Lubrication: Apply lubricant to moving parts to reduce friction and wear.

- Tightening: Check and tighten loose bolts or screws to ensure stability.

- Hydraulic fluid maintenance: Monitor fluid levels, check for leaks, and replace the fluid as needed.

7. Describe the different materials used in the construction of hydraulic chairs and their properties.

- Metal (steel, aluminum): Provides strength and durability for the frame and base.

- Plastic: Used for seat and backrest components, offering comfort and ease of cleaning.

- Fabric or leather: Upholstery materials that enhance comfort and aesthetics.

- Hydraulic oil: Incompressible fluid that transmits power and lifts the chair.

8. Explain the quality control measures implemented in the manufacturing process of hydraulic chairs.

- Material inspection: Ensuring the quality and compliance of raw materials.

- Component testing: Verifying the performance and reliability of individual components.

- Assembly inspection: Checking for proper assembly and alignment.

- Functional testing: Testing the chair’s lifting, lowering, and stability functions.

9. Discuss the environmental considerations related to the disposal and recycling of hydraulic chairs.

Proper disposal and recycling practices are essential to minimize environmental impact:

- Hydraulic oil disposal: Follow regulations for the safe disposal of hydraulic fluid, preventing contamination.

- Material recycling: Separate and recycle metal, plastic, and fabric components according to local regulations.

- Responsible disposal: Ensure that non-recyclable components are disposed of in an environmentally sound manner.

10. What are the advancements and emerging technologies in the design and manufacturing of hydraulic chairs?

- Ergonomic enhancements: Designs that prioritize user comfort and support.

- Smart technology integration: Features such as electric height adjustment and remote control.

- Sustainable materials: Use of eco-friendly materials and processes to reduce environmental impact.

- Automated manufacturing: Utilizing advanced technologies to improve efficiency and consistency.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hydraulic Chair Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hydraulic Chair Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Hydraulic Chair Assembler is responsible for assembling and installing hydraulic chairs, ensuring their proper functionality and adherence to safety standards. The key job responsibilities include:

1. Assembly and Installation

Assembling hydraulic chairs according to blueprints and specifications.

- Installing hydraulic cylinders, pumps, and other components.

- Connecting hydraulic lines and fittings.

2. Quality Assurance

Inspecting assembled chairs for defects and ensuring compliance with quality standards.

- Testing hydraulic systems for leaks and proper operation.

- Adjusting and calibrating chairs to meet specifications.

3. Maintenance and Repair

Performing routine maintenance and repairs on hydraulic chairs.

- Replacing worn or damaged hydraulic components.

- Troubleshooting and diagnosing hydraulic system problems.

4. Safety and Compliance

Adhering to safety protocols and regulations related to hydraulic chair assembly and installation.

- Wearing appropriate safety gear, such as gloves and safety glasses.

- Following lockout/tagout procedures when working on hydraulic systems.

Interview Tips

To ace an interview for a Hydraulic Chair Assembler position, consider the following tips:

1. Research the Company and Position

Familiarize yourself with the company’s background, products, and industry standing. Understand the specific responsibilities and requirements of the Hydraulic Chair Assembler role.

- Visit the company website and social media pages.

- Read industry articles and trade publications.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills in hydraulic systems, assembly, and maintenance. Showcase any relevant certifications or previous experience in similar roles.

- Quantify your accomplishments, using specific metrics and figures.

- Use industry-specific keywords in your resume and interview responses.

3. Demonstrate Safety Consciousness

Convey your understanding of the safety regulations and protocols related to hydraulic systems. Highlight your experience in following safety procedures and maintaining a safe work environment.

- Provide examples of how you have implemented safety measures in your previous roles.

- Discuss your knowledge of industry best practices and standards.

4. Be Prepared for Technical Questions

Anticipate questions about hydraulic systems, assembly techniques, and troubleshooting procedures. Practice answering these questions clearly and concisely, providing logical explanations.

- Review common hydraulic principles and components.

- Prepare for questions about assembly sequences and quality control processes.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Hydraulic Chair Assembler role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.