Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Hydraulic Elevator Constructor position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

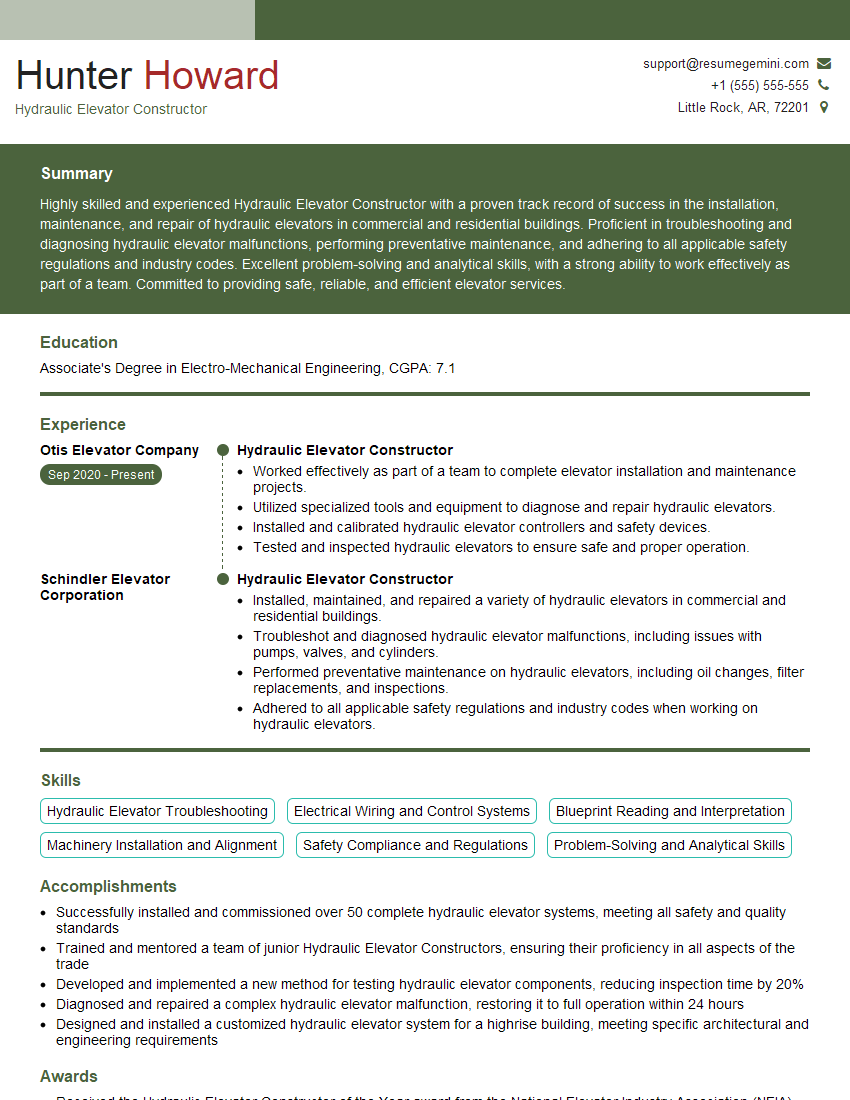

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hydraulic Elevator Constructor

1. Explain the process of installing a hydraulic elevator system from start to finish.

Here is a step-by-step process of installing a hydraulic elevator system from start to finish:

- Planning and design: This phase includes determining the elevator’s specifications and requirements, selecting the appropriate equipment, and creating a detailed installation plan.

- Site preparation: The installation site is prepared by excavating the pit, constructing the hoistway, and installing the necessary electrical and mechanical infrastructure.

- Equipment installation: The elevator components, including the hydraulic power unit, pump, cylinder, and car, are installed and assembled.

- Piping and wiring: The hydraulic piping and electrical wiring are connected to the elevator components, ensuring proper operation and safety.

- Car finishes and fixtures: The elevator car is finished with the desired materials, such as flooring, walls, ceiling, lighting, and control panel.

- Testing and commissioning: The elevator system is thoroughly tested to ensure it meets all safety and performance standards before it is put into operation.

- Acceptance and handover: Upon satisfactory testing, the elevator system is formally accepted by the client, and the operation and maintenance responsibilities are transferred.

2. Describe the different types of hydraulic elevator valves and their functions.

- Pressure relief valve: This valve protects the hydraulic system from excessive pressure by diverting excess fluid back to the reservoir.

- Check valve: This valve allows fluid to flow in one direction only, preventing backflow and maintaining pressure in the system.

- Flow control valve: This valve regulates the flow rate of hydraulic fluid, controlling the speed and movement of the elevator car.

- Selector valve: This valve directs the flow of hydraulic fluid to different parts of the system, such as the up/down cylinders or the auxiliary power unit.

3. What are the most common problems that can occur with hydraulic elevator systems and how do you troubleshoot them?

Some common problems that can occur with hydraulic elevator systems and troubleshooting tips include:

- Hydraulic leaks: Check for leaks in the piping, hoses, cylinders, and other components. Tighten connections, replace damaged parts, and bleed the system to remove air.

- Pump failure: Inspect the pump for wear, damage, or contamination. Check the oil level and quality, and replace or repair the pump as necessary.

- Valve malfunctions: Clean or replace faulty valves, ensure proper adjustment, and check for blockages or debris.

- Electrical issues: Check for loose connections, damaged wiring, or faulty components. Inspect the control panel, motor, and other electrical equipment.

4. How do you ensure the safety of hydraulic elevator systems?

To ensure the safety of hydraulic elevator systems, the following measures can be taken:

- Regular inspections and maintenance: Conduct routine inspections and maintenance to identify and address potential issues before they become major problems.

- Safety devices: Install and maintain safety devices such as overspeed governors, emergency stop switches, and door interlocks to prevent accidents.

- Hydraulic fluid management: Use high-quality hydraulic fluid and monitor its condition regularly. Change the fluid and filters as per the manufacturer’s recommendations.

- Training and certification: Ensure that personnel working on hydraulic elevator systems are properly trained and certified to handle the equipment safely.

5. What are the advantages and disadvantages of hydraulic elevator systems compared to other types of elevators?

Advantages:

- Smoother ride quality due to the use of hydraulic fluid.

- Lower installation cost compared to traction elevators.

- Suitable for low-rise buildings with limited space requirements.

- Less noise and vibration during operation.

Disadvantages:

- Limited travel height compared to traction elevators.

- Higher energy consumption due to the constant use of hydraulic fluid.

- Requires regular maintenance and fluid changes.

- Environmental concerns related to hydraulic fluid leaks and disposal.

6. How do you stay up-to-date with the latest advancements in hydraulic elevator technology?

- Attend industry conferences and exhibitions.

- Read technical journals and publications.

- Participate in online forums and discussion groups.

- Consult with manufacturers and experts in the field.

- Pursue professional development opportunities, such as workshops and training programs.

7. Describe your experience in working with hydraulic elevator control systems.

In my previous role as a Hydraulic Elevator Constructor, I was responsible for the installation, maintenance, and repair of various hydraulic elevator control systems. I have experience working with both relay-based and microprocessor-based control systems. I am familiar with the principles of elevator control, including position sensing, door operation, and safety interlocks. I have also worked on the integration of elevator control systems with building management systems.

8. What is the importance of proper lubrication in hydraulic elevator systems?

- Reduces friction and wear on moving parts, extending their lifespan.

- Prevents corrosion and rust, maintaining the integrity of components.

- Improves the efficiency and performance of the elevator system.

- Reduces the risk of hydraulic fluid leaks and failures.

9. How do you handle working in confined spaces, such as elevator shafts?

- Always follow proper safety procedures and wear appropriate personal protective equipment (PPE).

- Use proper tools and techniques to minimize the risk of injury.

- Maintain good communication with colleagues and supervisors while working in confined spaces.

- Be aware of potential hazards, such as electrical equipment, hydraulic lines, and moving parts.

10. What are your career goals as a Hydraulic Elevator Constructor?

- To continue developing my skills and knowledge in the field of hydraulic elevator construction.

- To contribute to the safe and efficient installation and maintenance of hydraulic elevator systems.

- To work on challenging projects and expand my experience in the industry.

- To become a certified Hydraulic Elevator Constructor and stay up-to-date with the latest advancements in the field.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hydraulic Elevator Constructor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hydraulic Elevator Constructor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Hydraulic Elevator Constructors are responsible for the installation, maintenance, and repair of hydraulic elevators. They work with blueprints and schematics to ensure that elevators are installed correctly, and they use specialized tools and equipment to perform their work.

1. Installation

Hydraulic Elevator Constructors install new elevators in buildings. They work with blueprints and schematics to determine the location of the elevator shaft and the equipment that will be needed. They then assemble the elevator components and install them in the shaft.

- Assemble and install elevator components, including the car, hoistway, and hydraulic system.

- Ensure that elevators meet all safety codes and regulations.

2. Maintenance

Hydraulic Elevator Constructors perform regular maintenance on elevators to ensure that they are operating safely and efficiently. They inspect the elevator components, lubricate moving parts, and replace worn or damaged parts.

- Inspect and lubricate elevator components to prevent breakdowns.

- Test elevators to ensure that they are operating safely.

3. Repair

Hydraulic Elevator Constructors repair elevators that have broken down. They diagnose the problem and then replace or repair the damaged parts. They also perform emergency repairs to ensure that elevators are back in operation as quickly as possible.

- Diagnose and repair elevator problems.

- Replace or repair damaged elevator components.

4. Troubleshooting

Hydraulic Elevator Constructors troubleshoot elevators that are not operating properly. They use their knowledge of elevator systems to identify the problem and then make the necessary repairs.

- Identify and resolve elevator problems.

- Use diagnostic tools to troubleshoot elevator systems.

Interview Tips

Here are some tips to help you ace your interview for a Hydraulic Elevator Constructor position:

1. Research the company and the position

Before your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and the specific requirements of the job.

- Visit the company’s website.

- Read articles about the company in industry publications.

- Talk to people who work for the company.

2. Prepare answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Prepare answers to these questions in advance so that you can deliver them confidently and concisely.

- Practice answering common interview questions with a friend or family member.

- Use the STAR method to answer interview questions.

3. Dress professionally

First impressions matter, so make sure to dress professionally for your interview. This means wearing a suit or business casual attire.

- Choose clothes that are clean and pressed.

- Make sure your shoes are polished.

4. Be on time

Punctuality is important, so make sure to arrive for your interview on time. This shows the interviewer that you are respectful of their time.

- Plan your route to the interview in advance.

- Give yourself plenty of time to get to the interview location.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Hydraulic Elevator Constructor, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Hydraulic Elevator Constructor positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.