Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Hydraulic Hammer Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Hydraulic Hammer Operator so you can tailor your answers to impress potential employers.

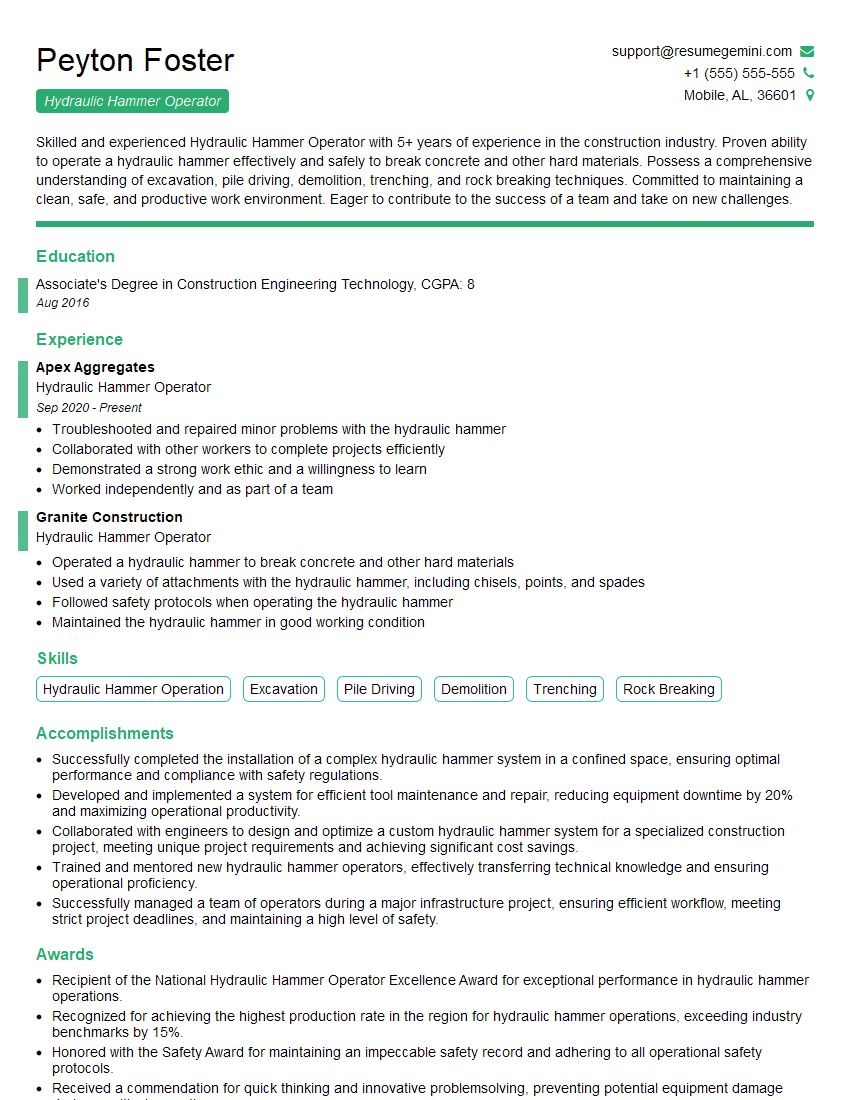

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hydraulic Hammer Operator

1. How do you determine the correct hydraulic pressure for the hydraulic hammer?

- Check the manufacturer’s specifications for the hammer.

- Use a pressure gauge to measure the actual pressure at the hammer.

- Observe the performance of the hammer and adjust the pressure accordingly.

2. What are the safety precautions that you should take when operating a hydraulic hammer?

General Safety Precautions

- Wear appropriate personal protective equipment (PPE), including hard hat, safety glasses, earplugs, and gloves.

- Be aware of your surroundings and keep others at a safe distance.

- Inspect the hammer and hydraulic system before each use.

- Never operate the hammer if it is damaged or leaking.

Specific Safety Precautions for Hydraulic Hammers

- Be aware of the recoil force of the hammer and take steps to prevent injury.

- Never operate the hammer near overhead wires or other potential hazards.

- Use a hydraulic hammer only for its intended purpose.

3. What are the different types of hydraulic hammers and what are their applications?

- Handheld hydraulic hammers: These are small, portable hammers that are used for breaking concrete, asphalt, and other materials. They are typically used in construction and demolition applications.

- Boom-mounted hydraulic hammers: These are larger hammers that are mounted on a boom or excavator. They are used for a variety of applications, including pile driving, rock breaking, and excavation.

- Subsea hydraulic hammers: These are specialized hammers that are used for underwater applications, such as offshore construction and pipeline installation.

4. What are the common problems that you may encounter when operating a hydraulic hammer?

- Low hydraulic pressure: This can be caused by a variety of factors, including a faulty pump, a clogged filter, or a leak in the hydraulic system.

- Hammer not firing: This can be caused by a variety of factors, including a faulty solenoid, a broken spring, or a clogged pilot line.

- Hammer recoil: This is the force that is generated when the hammer strikes an object. It can be a hazard if the operator is not prepared for it.

5. How do you troubleshoot and repair a hydraulic hammer?

- Identify the problem: The first step is to identify the problem by observing the symptoms and checking the hydraulic system.

- Troubleshoot the problem: Once the problem has been identified, the next step is to troubleshoot the problem by checking the components of the hydraulic system.

- Repair the problem: Once the problem has been troubleshooted, the next step is to repair the problem by replacing the faulty components.

6. What are the maintenance requirements for a hydraulic hammer?

- Daily maintenance: This includes checking the hydraulic fluid level, cleaning the hammer, and greasing the moving parts.

- Weekly maintenance: This includes checking the hydraulic hoses and fittings for leaks, and inspecting the hammer for any signs of damage.

- Monthly maintenance: This includes changing the hydraulic fluid and filter, and performing a thorough inspection of the hammer.

7. What are the environmental regulations that apply to the operation of hydraulic hammers?

- Noise pollution: Hydraulic hammers can generate a lot of noise, so it is important to follow the local noise regulations when operating a hammer.

- Air pollution: Hydraulic hammers can also generate air pollution, so it is important to follow the local air pollution regulations when operating a hammer.

- Water pollution: Hydraulic hammers can also generate water pollution, so it is important to follow the local water pollution regulations when operating a hammer.

8. What are the different types of hydraulic fluids that can be used in a hydraulic hammer?

- Mineral oil: This is the most common type of hydraulic fluid used in hydraulic hammers. It is relatively inexpensive and has good performance characteristics.

- Synthetic oil: This type of hydraulic fluid is more expensive than mineral oil, but it has better performance characteristics, including a higher viscosity index and a longer lifespan.

- Biodegradable oil: This type of hydraulic fluid is more environmentally friendly than mineral oil or synthetic oil. It is made from renewable resources and is biodegradable.

9. What are the advantages of using a hydraulic hammer over other types of hammers?

- Power: Hydraulic hammers are very powerful, and they can break through even the toughest materials.

- Versatility: Hydraulic hammers can be used for a variety of applications, including breaking concrete, asphalt, rock, and ice.

- Controllability: Hydraulic hammers are very controllable, and the operator can adjust the force of the hammer to suit the application.

10. What are the disadvantages of using a hydraulic hammer?

- Cost: Hydraulic hammers are more expensive than other types of hammers.

- Maintenance: Hydraulic hammers require more maintenance than other types of hammers.

- Noise: Hydraulic hammers can generate a lot of noise.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hydraulic Hammer Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hydraulic Hammer Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Hydraulic Hammer Operator, you will play a crucial role in the construction and demolition industry. Your key responsibilities will encompass various aspects, including:

1. Equipment Operation

Skilled operation and maintenance of hydraulic hammers, including proper handling, positioning, and maneuvering of the equipment.

- Implement safety protocols to ensure proper functioning and prevent accidents.

- Perform routine inspections and maintenance to keep the hydraulic hammer in optimal working condition.

2. Site Preparation and Planning

Assist in preparing the worksite, following blueprints and specifications to determine the precise location for hydraulic hammer operation.

- Assess the ground conditions and select appropriate techniques to maximize efficiency and minimize damage.

- Stay informed about site safety regulations and implement them diligently to ensure a safe work environment.

3. Breaking and Demolition

Execute precise and controlled hydraulic hammer operations to break concrete, asphalt, and other materials according to project requirements.

- Utilize various techniques, such as top-down, bottom-up, and stitch-breaking to achieve the desired results.

- Monitor the progress of the breaking and demolition work, making necessary adjustments to ensure accuracy and efficiency.

4. Material Handling

Operate hydraulic hammers to move and handle materials on construction sites.

- Use attachments, such as chisels and moil points, to perform specific tasks like breaking, chipping, and compacting.

- Work in a team environment to coordinate the safe and efficient movement of materials.

Interview Tips

Preparing thoroughly for your interview as a Hydraulic Hammer Operator is essential to showcase your skills and increase your chances of success. Here are some valuable tips to guide you:

1. Research the Company and Role

Take the time to research the company’s history, values, and current projects to demonstrate your interest and knowledge.

- Visit the company’s website, read industry news, and explore their social media presence.

- Understand the specific requirements of the Hydraulic Hammer Operator role and tailor your responses accordingly.

2. Highlight Your Expertise

Emphasize your experience in operating hydraulic hammers, including the types of equipment you have worked with and the techniques you are proficient in.

- Provide specific examples of projects where you successfully used hydraulic hammers to break concrete, asphalt, or other materials.

- Quantify your accomplishments whenever possible, using metrics such as the amount of material broken or the time saved.

3. Showcase Your Safety Mindset

Safety is paramount in construction. Emphasize your commitment to following safety protocols, wearing appropriate protective gear, and maintaining a safe work environment.

- Share examples of how you have implemented safety measures on previous projects.

- Explain your understanding of industry safety regulations and how you adhere to them.

4. Demonstrate Your Problem-Solving Abilities

Hydraulic hammer operators often encounter unexpected challenges on the job. Prepare to discuss your problem-solving skills and how you handle unexpected situations.

- Describe a situation where you faced a problem with a hydraulic hammer and explain how you diagnosed and resolved it.

- Discuss your approach to troubleshooting and finding innovative solutions to challenges.

5. Practice Your Communication Skills

Clear and effective communication is crucial for success in this role. Practice your communication skills by rehearsing your answers to common interview questions.

- Speak confidently and articulate your thoughts clearly.

- Be prepared to listen attentively and ask clarifying questions.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Hydraulic Hammer Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.