Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Hydraulic Jack Mechanic interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Hydraulic Jack Mechanic so you can tailor your answers to impress potential employers.

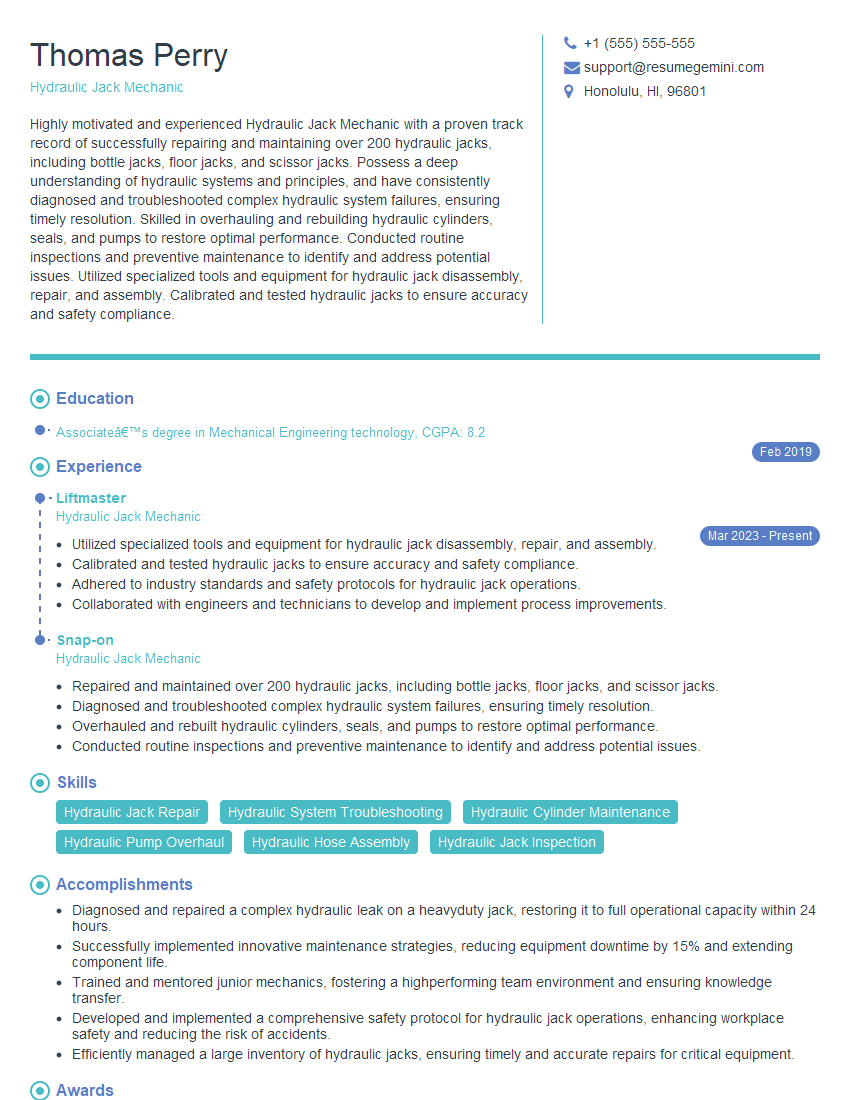

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hydraulic Jack Mechanic

1. Explain the working principle of a hydraulic jack?

- Hydraulic jacks utilize Pascal’s principle, which states that pressure applied to a confined fluid is transmitted equally throughout the fluid.

- When force is applied to the hydraulic fluid within the jack, it pressurizes the fluid.

- This pressure then acts on the piston, causing it to extend or retract, thereby lifting or lowering the load.

2. Describe the different types of hydraulic jacks and their applications?

Piston jacks

- Single-acting: Fluid pressure extends the piston, while retraction occurs by gravity.

- Double-acting: Fluid pressure controls both the extension and retraction of the piston.

Bottle jacks

- Portable and compact design.

- Used for lifting heavy objects in confined spaces.

Floor jacks

- Larger and more powerful than bottle jacks.

- Designed for use in automotive repair shops and industrial settings.

3. What are the safety precautions to be taken when using hydraulic jacks?

- Inspect the jack for any damage or leaks before use.

- Use jacks only on stable and level surfaces.

- Never exceed the rated capacity of the jack.

- Place blocks or cribbing under the load as a safety backup.

- Avoid sudden movements or overloading the jack.

4. How do you troubleshoot common problems encountered with hydraulic jacks?

Jack does not lift

- Check for leaks in the system.

- Inspect the hydraulic fluid level and add fluid if necessary.

- Check for blockages in the hydraulic lines.

Jack leaks

- Check for damaged seals or hoses.

- Replace the faulty components as necessary.

Jack is unstable

- Ensure the jack is placed on a stable surface.

- Check for any loose bolts or pins.

5. How do you maintain a hydraulic jack for optimal performance?

- Regularly check the hydraulic fluid level and replace as needed.

- Inspect the seals and hoses for wear and damage.

- Clean the jack and remove any dirt or debris.

- Lubricate moving parts as per the manufacturer’s recommendations.

6. What are the advantages of using hydraulic jacks over mechanical jacks?

- Hydraulic jacks provide greater force and lifting capacity.

- They offer smoother operation and precise control of the load.

- Hydraulic jacks are more compact and portable than mechanical jacks.

7. Describe the use of a hydraulic jack in lifting a vehicle for tire changes or repairs?

- Position the jack at the designated lift point indicated in the vehicle’s manual.

- Pump the jack handle to raise the vehicle to the desired height.

- Place jack stands under the vehicle for added stability.

- Perform the tire change or repair.

- Lower the vehicle using the jack and remove the jack stands.

8. How do you calculate the pressure required to lift a load using a hydraulic jack?

- Force (F) = Weight of the load (W)

- Pressure (P) = F / Area of the piston (A)

- Determine the piston area from the jack’s specifications.

9. Explain the role of a pressure relief valve in a hydraulic jack?

- Prevents excessive pressure buildup within the hydraulic system.

- Automatically opens when pressure exceeds a predetermined level.

- Protects the jack and the user from potential accidents.

10. Describe the importance of using the correct hydraulic fluid for a hydraulic jack?

- Ensures proper lubrication and protection of internal components.

- Prevents corrosion, wear, and premature failure.

- Different hydraulic fluids have specific viscosities and additives suitable for various operating conditions.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hydraulic Jack Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hydraulic Jack Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Hydraulic Jack Mechanics are responsible for maintaining, repairing, and inspecting hydraulic jacks used in various industries such as construction, manufacturing, and transportation. Here are some key job responsibilities:

1. Maintenance and Inspection

Regularly inspect hydraulic jacks for any signs of damage, wear, or leaks, ensuring they are in good working condition.

- Check hydraulic fluid levels and replenish as necessary.

- Inspect hoses, seals, and other components for damage or leaks.

2. Repair and Troubleshooting

Diagnose and repair malfunctioning hydraulic jacks, identifying and fixing any mechanical or hydraulic issues.

- Replace worn or damaged parts such as seals, hoses, and valves.

- Adjust and calibrate hydraulic pressure and flow to ensure optimal performance.

3. Installation and Commissioning

Install new hydraulic jacks according to manufacturer’s specifications and ensure they are properly commissioned and tested.

- Mount jacks securely and connect them to hydraulic systems.

- Test and verify jack performance before putting it into operation.

4. Safety and Compliance

Adhere to safety regulations and industry standards related to the use, maintenance, and repair of hydraulic jacks.

- Maintain a clean and organized work area to prevent accidents.

- Follow proper lockout/tagout procedures when working on hydraulic systems.

Interview Tips

To prepare for an interview as a Hydraulic Jack Mechanic, consider the following tips:

1. Research the Company and Role

Learn about the company’s history, values, and the specific requirements of the Hydraulic Jack Mechanic position.

- Visit the company’s website and read industry news related to hydraulic systems.

- Identify key skills and experience mentioned in the job description and tailor your resume and cover letter accordingly.

2. Highlight Relevant Skills and Experience

Emphasize your technical abilities related to hydraulic jack maintenance and repair, including your knowledge of hydraulic principles, troubleshooting techniques, and safety regulations.

- Quantify your accomplishments with specific examples and metrics whenever possible.

- If you have experience with different types of hydraulic jacks or specific industries, mention these to demonstrate your versatility.

3. Prepare for Technical Questions

Expect technical questions related to hydraulic systems, such as:

- Describe the basic principles of hydraulics and how it applies to hydraulic jacks.

- Explain how to troubleshoot a hydraulic jack with a leaking seal.

4. Showcase Your Safety Awareness

Hydraulic Jack Mechanics must be highly safety-conscious. Highlight your understanding of safety protocols and your commitment to following them.

- Discuss your experience with lockout/tagout procedures and other safety precautions.

- Demonstrate your knowledge of industry standards for hydraulic jack maintenance and repair.

Next Step:

Now that you’re armed with the knowledge of Hydraulic Jack Mechanic interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Hydraulic Jack Mechanic positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini