Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Hydraulic Mechanic position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

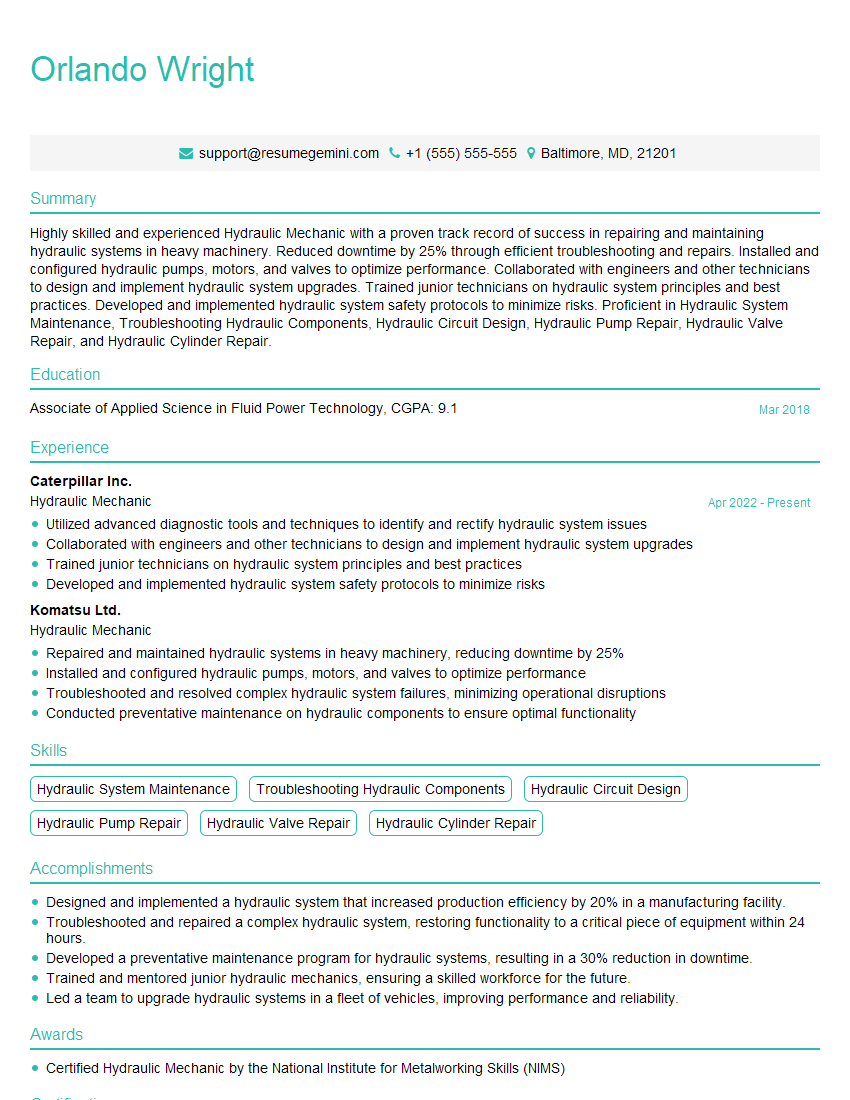

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hydraulic Mechanic

1. What are the different types of hydraulic systems and their applications?

* Linear hydraulic systems: Use linear actuators to move objects in a straight line. * Rotary hydraulic systems: Use rotary actuators to rotate objects. * Mobile hydraulic systems: Used in vehicles, such as forklifts and excavators. * Industrial hydraulic systems: Used in industrial machinery, such as presses and machine tools.

2. How do you diagnose and troubleshoot hydraulic system problems?

Troubleshooting steps:

- Gather information about the system and its symptoms.

- Inspect the system for leaks, loose connections, and other visible problems.

- Test the system components using pressure gauges, flow meters, and other diagnostic tools.

- Use a hydraulic schematic to identify the potential cause of the problem.

- Repair or replace the faulty components.

3. How do you maintain hydraulic systems to prevent failures?

- Regularly inspect the system for leaks, contamination, and other problems.

- Change the hydraulic fluid and filters as recommended by the manufacturer.

- Lubricate the moving parts of the system.

- Monitor the system pressure and temperature.

- Keep the system clean and free of debris.

4. What are the safety precautions that must be followed when working with hydraulic systems?

- Wear appropriate safety gear, including gloves, safety glasses, and ear protection.

- Do not work on a hydraulic system that is under pressure.

- Use caution when releasing pressure from a hydraulic system.

- Never attempt to repair a hydraulic hose or fitting that is under pressure.

- Be aware of the potential for hydraulic fluid leaks and fires.

5. What are the advantages and disadvantages of using hydraulic systems?

Advantages:

- High power density

- Precise control

- Compact design

- Low noise

Disadvantages:

- High cost

- Potential for leaks

- Sensitivity to contamination

6. How do you calculate the force and torque produced by a hydraulic cylinder?

Force:

F = P * A

where:

- F is the force in newtons

- P is the pressure in pascals

- A is the area of the cylinder in square meters

Torque:

T = P * V * D

where:

- T is the torque in newton-meters

- P is the pressure in pascals

- V is the volume of the cylinder in cubic meters

- D is the diameter of the cylinder in meters

7. How do you size a hydraulic pump for a specific application?

The size of the pump is determined by the flow rate and pressure required by the application. The flow rate is calculated by multiplying the speed of the actuator by the area of the cylinder. The pressure is determined by the load that the actuator is moving.

8. How do you select the right hydraulic fluid for a specific application?

The type of hydraulic fluid is determined by the operating temperature, pressure, and speed of the system. The viscosity of the fluid is also important. The viscosity is the resistance to flow. A higher viscosity fluid will provide better lubrication but will also increase the power consumption of the pump.

9. How do you connect hydraulic hoses and fittings?

Hydraulic hoses and fittings are connected using a variety of methods, including crimping, flaring, and welding. The type of connection is determined by the size and pressure of the system.

10. What are the different types of hydraulic valves and their functions?

There are a variety of hydraulic valves, each with its own function. Some of the most common types of hydraulic valves include:

- Check valves: Allow fluid to flow in only one direction.

- Relief valves: Limit the pressure in a hydraulic system.

- Directional control valves: Control the direction of fluid flow.

- Flow control valves: Control the flow rate of fluid.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hydraulic Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hydraulic Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Hydraulic Mechanics are responsible for a wide range of duties related to the maintenance and repair of hydraulic systems and components. Their responsibilities include:

1. Inspect and Diagnose

A Hydraulic Mechanic will inspect hydraulic systems and components for signs of wear and tear or damage. They will also diagnose the cause of any problems with the system and recommend solutions.

- Diagnose and repair malfunctioning hydraulic systems.

- Conduct maintenance inspections and troubleshooting.

2. Install and Maintain

They will also install and maintain hydraulic systems and components, ensuring that they are functioning properly. This includes tasks such as connecting hoses, installing valves, and maintaining fluid levels.

- Install, repair, and maintain hydraulic pumps, valves, cylinders, and other components.

- Fabricate and assemble hydraulic lines and fittings.

3. Test and Repair

Hydraulic Mechanics will also test and repair hydraulic systems and components. This involves running tests to identify any problems with the system and making repairs to ensure that the system is functioning properly.

- Test and adjust hydraulic systems to ensure proper operation.

- Troubleshoot and repair hydraulic system failures.

4. Other Duties

In addition to these key responsibilities, Hydraulic Mechanics may also perform other duties, such as:

- Providing technical support to customers.

- Training other employees on hydraulic systems and components.

Interview Tips

Preparing for a Hydraulic Mechanic interview can be a daunting task, but with the right tips and preparation, you can increase your chances of success.

1. Know Your Stuff

The best way to prepare for a Hydraulic Mechanic interview is to make sure you have a strong understanding of hydraulic principles. This includes knowledge of the different types of hydraulic systems, components, and fluids. You should also be familiar with the different types of hydraulic tests and repairs.

- Research the company and the specific position you are applying for.

- Review your resume and be prepared to discuss your skills and experience.

2. Practice Your Answers

Once you have a good understanding of hydraulic principles, you should practice answering common interview questions. This will help you feel more confident and prepared during the interview.

- Prepare answers to common interview questions, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”

- Practice your answers out loud so that you can deliver them smoothly and confidently.

3. Dress Professionally

First impressions matter, so make sure you dress professionally for your interview. This means wearing a suit or business casual attire.

- First impressions matter, so dress professionally for your interview.

- Make sure your clothes are clean, pressed, and fit well.

4. Be On Time

Punctuality is important, so make sure you arrive for your interview on time. This shows the interviewer that you are respectful of their time.

- Plan your route ahead of time and leave early to avoid any unexpected delays.

- If you do happen to be running late, call the interviewer and let them know.

5. Be Yourself

The most important thing is to be yourself during the interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not.

- Be honest and genuine in your answers.

- Don’t be afraid to ask questions or clarify anything you don’t understand.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Hydraulic Mechanic interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!