Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Hydraulic Miner, Blasting position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

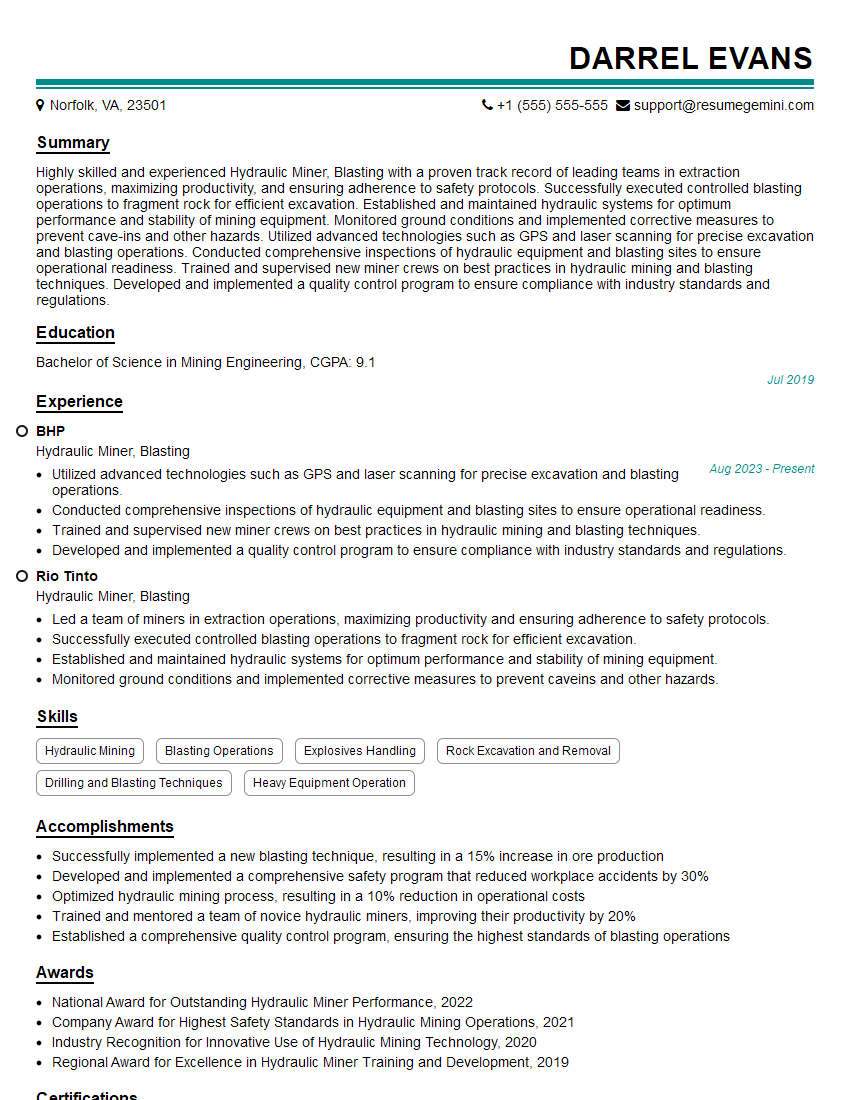

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hydraulic Miner, Blasting

1. What are the different types of drilling methods used in hydraulic mining?

- Jet piercing

- Rotary drilling

- Percussion drilling

2. How do you determine the optimal drilling pattern for a given blasting operation?

Factors to consider:

- Rock type and properties

- Desired fragmentation size

- Blasting agent being used

- Environmental conditions

Steps:

- Conduct a site survey

- Calculate the burden and spacing

- Determine the hole depth and inclination

- Adjust for specific conditions (e.g., jointing, fractures)

3. What are the safety precautions that must be taken when using explosives in mining?

- Obtain proper training and certification

- Follow all applicable regulations and guidelines

- Store and handle explosives safely

- Use appropriate blasting techniques

- Control access to blasting areas

- Inspect and maintain equipment regularly

- Have emergency response plans in place

4. How do you calculate the charge weight and explosive type required for a specific blasting operation?

- Estimate the rock volume to be blasted

- Determine the desired fragmentation size

- Calculate the specific charge (kg/m^3)

- Select an appropriate explosive type based on rock properties

- Calculate the charge weight by multiplying the specific charge by the rock volume

5. What are the different types of blasting techniques and when are they used?

Types of blasting techniques:

- Vertical cratering

- Horizontal cratering

- Bench blasting

- Toe blasting

- Presplitting

When to use each technique:

- Vertical cratering: Creating large craters in soft rock

- Horizontal cratering: Blasting in horizontal layers in hard rock

- Bench blasting: Removing large volumes of rock in open-pit mines

- Toe blasting: Breaking down large boulders or loosening rock before excavation

- Presplitting: Creating a controlled fracture plane to prevent excessive damage during main blasting

6. How do you troubleshoot common blasting problems such as misfires or excessive ground vibration?

Misfires:

- Check electrical connections

- Inspect blasting caps

- Verify timing sequence

Excessive ground vibration:

- Reduce charge weight or number of holes

- Increase burden or spacing

- Use delay blasting to minimize simultaneous detonation

- Employ vibration monitoring and mitigation systems

7. How do you monitor and control blasting operations to ensure safety and efficiency?

- Establish clear communication and coordination protocols

- Conduct pre-blast inspections and surveys

- Use electronic blasting systems for accurate timing

- Monitor vibration and air quality during blasting

- Analyze blasting data to optimize operations and minimize environmental impact

8. What are the environmental considerations that must be taken into account when conducting blasting operations?

- Noise and vibration control

- Dust and air quality management

- Water quality protection

- Wildlife and vegetation impact assessment

- Rehabilitation and restoration of affected areas

9. How do you stay up-to-date on the latest developments in hydraulic mining and blasting techniques?

- Attend industry conferences and seminars

- Read technical journals and publications

- Participate in professional organizations

- Consult with experts and manufacturers

- Seek opportunities for continuing education and training

10. How do you prioritize safety in your work as a Hydraulic Miner, Blasting?

- Always follow established safety protocols

- Wear appropriate personal protective equipment

- Inspect equipment regularly and maintain it in good condition

- Be aware of potential hazards and take appropriate precautions

- Communicate effectively with colleagues and supervisors

- Stay informed about new safety technologies and practices

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hydraulic Miner, Blasting.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hydraulic Miner, Blasting‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Hydraulic Miners, Blasting are responsible for a range of tasks related to blasting and mining operations. Their key responsibilities include:

1. Blasting Operations

Conducting blasting operations safely and effectively. This includes:

- Preparing and detonating explosives according to established procedures.

- Calculating and marking blast patterns.

- Monitoring and controlling blasting vibrations.

2. Mining Operations

Operating and maintaining hydraulic mining equipment for surface mining operations.

- Monitoring and adjusting hydraulic systems to ensure optimal performance.

- Conducting routine maintenance and repairs on equipment.

- Following established safety protocols while operating heavy machinery.

3. Quality Control

Ensuring the quality of extracted materials. This involves:

- Inspecting and testing mined materials to meet quality specifications.

- Maintaining quality control records and reporting any deviations.

4. Safety and Compliance

Adhering to all safety and regulatory requirements related to blasting and mining operations. This includes:

- Following established safety procedures and wearing appropriate personal protective equipment.

- Understanding and implementing environmental regulations.

Interview Tips

Preparing well for your interview can significantly increase your chances of success. Here are some key tips to help you ace the interview for a Hydraulic Miner, Blasting position:

1. Research the Company and Industry

Research the company you’re applying to, as well as the mining industry as a whole. This will help you understand the company’s operations, culture, and market position. Understanding industry trends and regulations will demonstrate your knowledge and interest in the field.

2. Highlight Relevant Skills and Experience

Focus on highlighting your skills and experience that are most relevant to the job. Emphasize your expertise in blasting operations, mining equipment maintenance, and safety procedures. Quantify your accomplishments with specific examples to demonstrate your impact on previous projects.

3. Prepare for Technical Questions

Be prepared for technical questions related to blasting and mining operations. Study concepts such as explosive properties, blast design, and hydraulic systems. Practice answering questions about safety protocols and industry regulations. You may also be asked about your experience with specific types of equipment or software.

4. Showcase Your Safety and Compliance Knowledge

Safety is paramount in blasting and mining operations. Emphasize your commitment to safety by highlighting your understanding of safety procedures and regulations. Explain how you prioritize safety in your work and maintain compliance with industry standards.

5. Prepare Questions for the Interviewers

Prepare thoughtful questions to ask the interviewers. This shows your interest in the position and the company. Ask about the company’s safety culture, growth opportunities, and environmental sustainability efforts.

Next Step:

Now that you’re armed with the knowledge of Hydraulic Miner, Blasting interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Hydraulic Miner, Blasting positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini