Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Hydraulic Press Servicer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

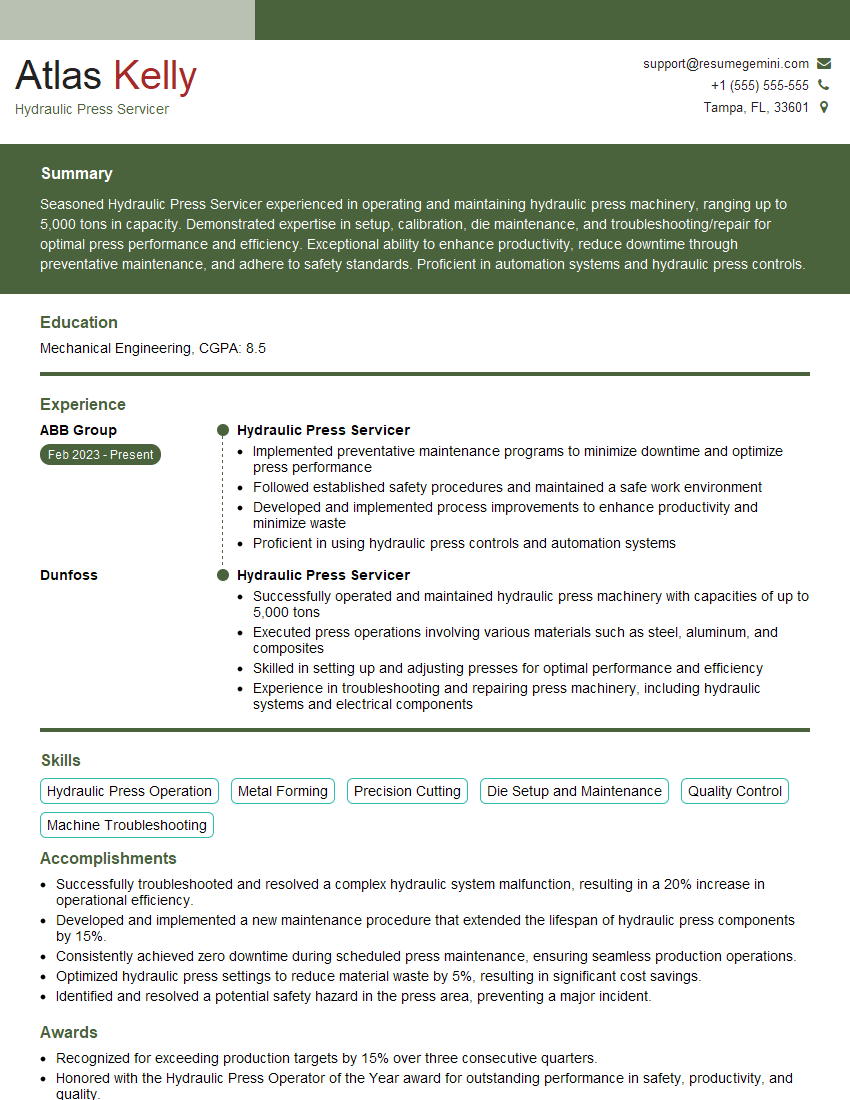

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hydraulic Press Servicer

1. Explain the basic principles of hydraulic press operation.

- Hydraulic Press is a machine that uses Pascal’s principle to multiply force.

- Pascal’s principle states that pressure applied to a confined fluid is transmitted equally in all directions throughout the fluid.

- In a hydraulic press, a small force is applied to a small piston, which creates pressure in the fluid.

- This pressure is then transmitted to a large piston, which creates a larger force.

- Hydraulic presses are used in a variety of industries, such as manufacturing, construction, and mining.

2. Describe the different types of hydraulic presses.

Mechanical Hydraulic Press

- Mechanical hydraulic presses use a mechanical pump to generate hydraulic pressure.

- These presses are typically used for low-pressure applications, such as stamping and forming.

Hydro-Pneumatic Hydraulic Press

- Hydro-pneumatic hydraulic presses use a combination of hydraulic and pneumatic pressure to generate high forces.

- These presses are typically used for more demanding applications, such as forging and extrusion.

3. What are the advantages of using hydraulic presses?

- Hydraulic presses offer a number of advantages over other types of presses.

- These advantages include:

- High force output

- Smooth and precise operation

- Low maintenance requirements

- Long service life

4. What are the safety considerations when operating a hydraulic press?

- There are a number of safety considerations that must be taken into account when operating a hydraulic press.

- These considerations include:

- Ensuring that the press is properly guarded.

- Wearing appropriate safety gear.

- Following all operating procedures.

- Never putting your hands or any other body parts near the moving parts of the press.

5. How do you troubleshoot a hydraulic press?

- Troubleshooting a hydraulic press involves a number of steps.

- These steps include:

- Identifying the problem.

- Checking the hydraulic system for leaks.

- Checking the electrical system for problems.

- Calibrating the press.

6. What are the different types of hydraulic fluids?

- There are a number of different types of hydraulic fluids.

- These fluids include:

- Mineral oils

- Synthetic oils

- Water-based fluids

7. How do you maintain a hydraulic press?

- Maintaining a hydraulic press involves a number of tasks.

- These tasks include:

- Regularly checking the hydraulic system for leaks.

- Changing the hydraulic fluid and filter according to the manufacturer’s recommendations.

- Inspecting the press for any signs of wear or damage.

- Calibrating the press regularly.

8. What are the different types of hydraulic press controls?

- There are a number of different types of hydraulic press controls.

- These controls include:

- Manual controls

- Semi-automatic controls

- Fully automatic controls

9. How do you set up a hydraulic press?

- Setting up a hydraulic press involves a number of steps.

- These steps include:

- Positioning the press on a level surface.

- Connecting the press to a power source.

- Filling the press with hydraulic fluid.

- Calibrating the press.

10. What are the different types of hydraulic press applications?

- Hydraulic presses are used in a variety of applications.

- These applications include:

- Stamping

- Forming

- Forging

- Extrusion

- Assembly

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hydraulic Press Servicer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hydraulic Press Servicer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Hydraulic Press Servicers are responsible for maintaining, repairing, and operating hydraulic presses in manufacturing environments. They ensure that these machines are operating safely and efficiently to produce high-quality products.

1. Machine Maintenance

Servicers perform regular maintenance on hydraulic presses, including lubricating moving parts, checking fluid levels, and inspecting hoses and fittings for leaks.

- Lubricates moving parts to prevent wear and tear

- Checks fluid levels to ensure proper lubrication

- Inspects hoses and fittings for leaks to prevent accidents

2. Troubleshooting and Repair

They troubleshoot and repair any problems that may arise with hydraulic presses, using their knowledge of hydraulic systems and mechanical components.

- Troubleshoots problems by identifying the source of the issue

- Repairs faulty components, such as pumps, valves, and cylinders

- Replaces worn or damaged parts to restore machine functionality

3. Quality Control

Servicers are responsible for ensuring that the parts produced by hydraulic presses meet quality standards. They inspect the parts for defects and make adjustments to the press settings as needed.

- Inspects parts for defects, such as scratches, dents, or cracks

- Makes adjustments to press settings to ensure optimal part quality

- Monitors production processes to prevent defects

4. Safety Compliance

Hydraulic press servicers must adhere to safety regulations when operating and servicing hydraulic presses. They are responsible for ensuring that the machines are operated safely and that all safety devices are in place and functioning properly.

- Follows safety regulations related to hydraulic press operation

- Inspects safety devices, such as guards and interlocks, to ensure proper function

- Reports any safety hazards to supervisors

Interview Tips

To ace an interview for a Hydraulic Press Servicer position, it is essential to prepare thoroughly and demonstrate your skills and experience. Here are some tips to help you prepare:

1. Research the Company and the Position

Take the time to research the company and the specific Hydraulic Press Servicer position you are applying for. Understand the company’s industry, products, and culture. This knowledge will help you tailor your answers to the interviewer’s questions.

- Visit the company’s website and social media pages

- Read articles and news about the company

- Check industry-specific websites and forums

2. Practice Your Answers

Prepare answers to common interview questions, such as “Tell me about yourself,” “Why are you interested in this position?” and “What are your strengths and weaknesses?” Rehearse your answers out loud to improve your delivery.

- Brainstorm potential questions and prepare concise answers

- Practice answering questions with a friend or family member

- Time yourself to ensure your answers are within the expected range

3. Highlight Your Skills and Experience

Emphasize your skills and experience that are relevant to the Hydraulic Press Servicer position. Quantify your accomplishments whenever possible to demonstrate the impact of your work.

- Highlight your experience in hydraulic systems maintenance and repair

- Mention any certifications or training you have obtained

- Provide examples of how you have improved efficiency or reduced downtime

4. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview shows that you are interested in the position and the company. Prepare a few questions that demonstrate your engagement and curiosity.

- Ask about the company’s growth plans

- Inquire about opportunities for professional development

- Ask about the company’s safety record and environmental practices

5. Follow Up

After the interview, send a thank-you note to the interviewer within 24 hours. Express your appreciation for their time and reiterate your interest in the position. You can also use this opportunity to clarify any points from the interview or provide additional information.

- Thank the interviewer for their time

- Reiterate your interest in the position

- Clarify any points from the interview or provide additional information

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Hydraulic Press Servicer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.