Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Hydraulic Rock Drill Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

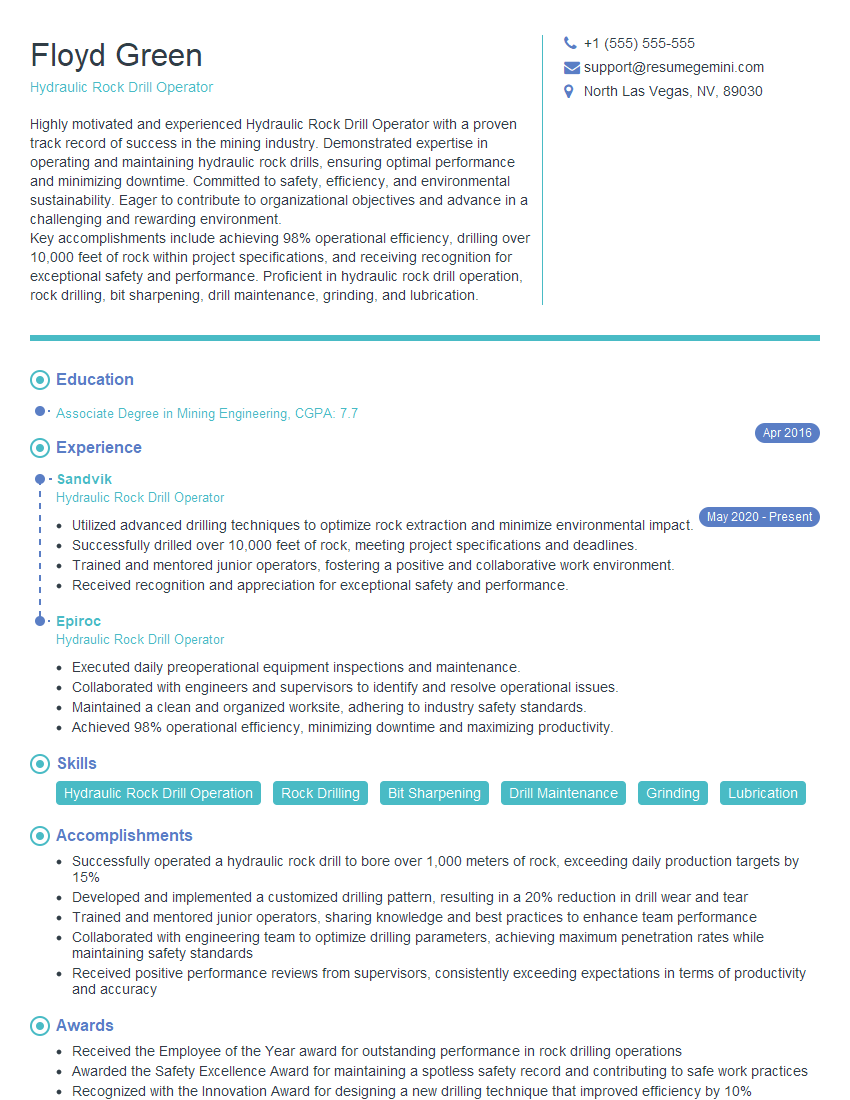

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hydraulic Rock Drill Operator

1. How do you ensure that the hydraulic rock drill is operated safely and efficiently?

To ensure safe and efficient operation of the hydraulic rock drill, I adhere to the following key measures:

- Thorough Inspection: I conduct pre-shift inspections to verify the machine’s overall condition, including hydraulic hoses, connections, and drill rods.

- Proper Setup: I set up the drill securely, ensuring a stable footing and adjusting the drilling parameters based on rock conditions and project requirements.

2. Describe the different types of drill bits used in hydraulic rock drilling and their applications.

Types of Drill Bits

- Chisel Bits: Used to create short holes and break rocks in confined spaces.

- Cross Bits: Designed for drilling holes with larger diameters in medium to hard rock formations.

Applications

- Construction: Foundation excavation, trenching, and tunneling.

- Mining: Cutting, blasting, and extraction of minerals from underground or surface mines.

3. How do you maintain optimal hydraulic pressure and flow rate for efficient drilling?

Maintaining optimal hydraulic pressure and flow rate is crucial for efficient drilling. I employ the following techniques:

- Regular Monitoring: I continuously monitor pressure and flow rate gauges to ensure they are within recommended ranges.

- Pump Adjustment: If necessary, I adjust the hydraulic pump to regulate pressure and flow to meet the specific drilling requirements.

4. What troubleshooting steps would you take if the hydraulic rock drill experiences a sudden loss of power?

In the event of a sudden loss of power, I would systematically follow these troubleshooting steps:

- Check Power Source: Verify that the drill is properly connected to a reliable power source and that there are no electrical faults.

- Inspect Hydraulic System: Examine hoses, connections, and components for leaks, blockages, or other issues that may hinder fluid flow.

5. How do you interpret rock drill performance data to optimize drilling operations?

I analyze rock drill performance data to identify areas for improvement and optimize drilling operations. Key metrics I evaluate include:

- Drill Penetration Rate: Assesses the efficiency of the drill in breaking and removing rock.

- Hydraulic Pressure and Flow Rate: Optimizing these parameters improves drilling speed and reduces wear on the drill.

6. What are the common safety precautions you observe while operating a hydraulic rock drill?

To ensure safety during operation, I adhere to the following precautions:

- Proper PPE: Always wear appropriate personal protective equipment, including safety glasses, gloves, and hearing protection.

- Stable Footing: Ensure the drill is positioned on a level and stable surface to prevent overturning.

7. How do you handle different rock formations and their impact on drilling efficiency?

I adapt my drilling techniques based on the rock formation encountered:

- Hard Rock: Use high-quality drill bits, apply additional pressure, and adjust drilling parameters to minimize wear and tear.

- Soft Rock: Can require less pressure, but attention to bit selection and proper hole cleaning is essential for efficient drilling.

8. Describe the procedure for replacing a worn-out drill bit on a hydraulic rock drill.

- Safety First: Ensure the drill is powered off and depressurized before any maintenance.

- Remove Chuck: Carefully unscrew the chuck that holds the drill bit.

- Extract Worn Bit: Use the appropriate tools to extract the worn-out drill bit safely.

- Insert New Bit: Insert the new drill bit into the chuck and tighten securely.

9. How do you minimize environmental impact during hydraulic rock drilling operations?

I take the following measures to reduce environmental impact:

- Control Noise and Vibration: Use noise-suppressing equipment and vibrationdampening techniques to minimize noise and ground disturbance.

- Proper Waste Disposal: Dispose of drilling fluids and rock cuttings responsibly to prevent soil contamination.

10. Describe the maintenance schedule you follow for a hydraulic rock drill.

- Daily Checks: Inspect hydraulic hoses, connections, and fluid levels.

- Weekly Maintenance: Clean and lubricate drill components, check drill bit sharpness.

- Monthly Servicing: Comprehensive inspection and adjustment of hydraulic system, replacement of worn parts.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hydraulic Rock Drill Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hydraulic Rock Drill Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Hydraulic Rock Drill Operator is primarily responsible for operating hydraulic rock drills in a variety of industries, including mining, quarrying, and construction. This job requires expertise in handling heavy machinery and in-depth knowledge of safety regulations and operating procedures. The key responsibilities of a Hydraulic Rock Drill Operator include:

1. Operating Hydraulic Rock Drills

This is the primary responsibility of a Hydraulic Rock Drill Operator, involving using hydraulic rock drills to bore holes into rock formations. The operator must be proficient in setting up and operating the drill, as well as in handling drill bits and other accessories.

- Setting up and operating hydraulic rock drills.

- Loading and unloading drill bits and other accessories.

- Monitoring drill performance and making necessary adjustments.

- Ensuring that the drill is operating safely and efficiently.

2. Maintaining and Servicing Hydraulic Rock Drills

Maintaining and servicing hydraulic rock drills is crucial for ensuring optimal performance and safety. The operator must be able to perform basic maintenance tasks, such as lubricating and cleaning the drill, as well as more complex repairs, such as replacing worn parts.

- Performing basic maintenance tasks, such as lubricating and cleaning the drill.

- Inspecting the drill for any signs of wear or damage.

- Replacing worn or damaged parts.

- Troubleshooting and resolving any mechanical issues that may arise.

3. Planning and Drilling Operations

Planning and drilling operations involve determining the best approach for drilling holes into rock formations. The operator must consider factors such as the type of rock, the depth of the holes, and the desired accuracy. The operator must also be able to follow drilling plans and make adjustments as needed.

- Determining the best drilling approach for different rock formations.

- Creating and following drilling plans.

- Making adjustments to drilling plans as needed.

- Ensuring that drilling operations are carried out safely and efficiently.

4. Safety and Environmental Compliance

Safety and environmental compliance are of utmost importance in the operation of hydraulic rock drills. The operator must be familiar with all relevant safety regulations and environmental regulations and must follow them strictly. The operator must also be able to identify and mitigate potential hazards.

- Following all relevant safety regulations and environmental regulations.

- Identifying and mitigating potential hazards.

- Ensuring that drilling operations are carried out safely and with minimal environmental impact.

- Reporting any unsafe or environmentally hazardous conditions.

Interview Tips

Preparing thoroughly for an interview is essential for making a positive impression and increasing your chances of getting the job. Here are some interview tips and hacks to help you ace your interview for a Hydraulic Rock Drill Operator position:

1. Research the Company and the Position

Start by researching the company and the specific position you are applying for. This will help you understand the company’s culture, values, and goals, as well as the specific responsibilities and requirements of the role. You can visit the company website, read industry news, and connect with employees on LinkedIn to gather relevant information.

- Example: You could mention that you are impressed by the company’s commitment to sustainability and that you are eager to contribute your expertise in environmentally responsible drilling practices.

2. Highlight Your Skills and Experience

During the interview, be sure to highlight your skills and experience that are relevant to the job. Focus on your proficiency in operating hydraulic rock drills, your ability to perform maintenance and repairs, and your knowledge of safety regulations.

- Example: You could provide specific examples of projects where you successfully used your skills to overcome drilling challenges and achieve project goals.

3. Demonstrate Your Safety Consciousness

Safety is a top priority for Hydraulic Rock Drill Operators. Emphasize your commitment to safety and your understanding of safety regulations and procedures. Share examples of how you have implemented safety measures in your previous roles and how you ensure compliance with industry standards.

- Example: You could mention that you have a proven track record of working safely in hazardous environments and that you are always vigilant in identifying and mitigating potential risks.

4. Ask Informed Questions

Asking thoughtful questions during the interview shows that you are engaged and interested in the position. Prepare a list of questions about the company, the role, and the industry. This demonstrates your enthusiasm and eagerness to learn more about the opportunity.

- Example: You could ask about the company’s plans for future projects, the training and development opportunities available, or the company’s approach to environmental sustainability.

5. Practice Your Answers

Practice answering common interview questions to build confidence and improve your delivery. Consider the potential questions you may face, such as those related to your experience, skills, safety practices, and career goals. Prepare concise and well-structured responses that showcase your strengths and qualifications.

- Example: You could practice answering questions such as “Tell me about your experience in operating hydraulic rock drills,” “How do you ensure safety in your drilling operations,” or “What are your career goals in this industry.”

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Hydraulic Rock Drill Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.