Are you gearing up for a career in Hydraulic Specialist? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Hydraulic Specialist and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

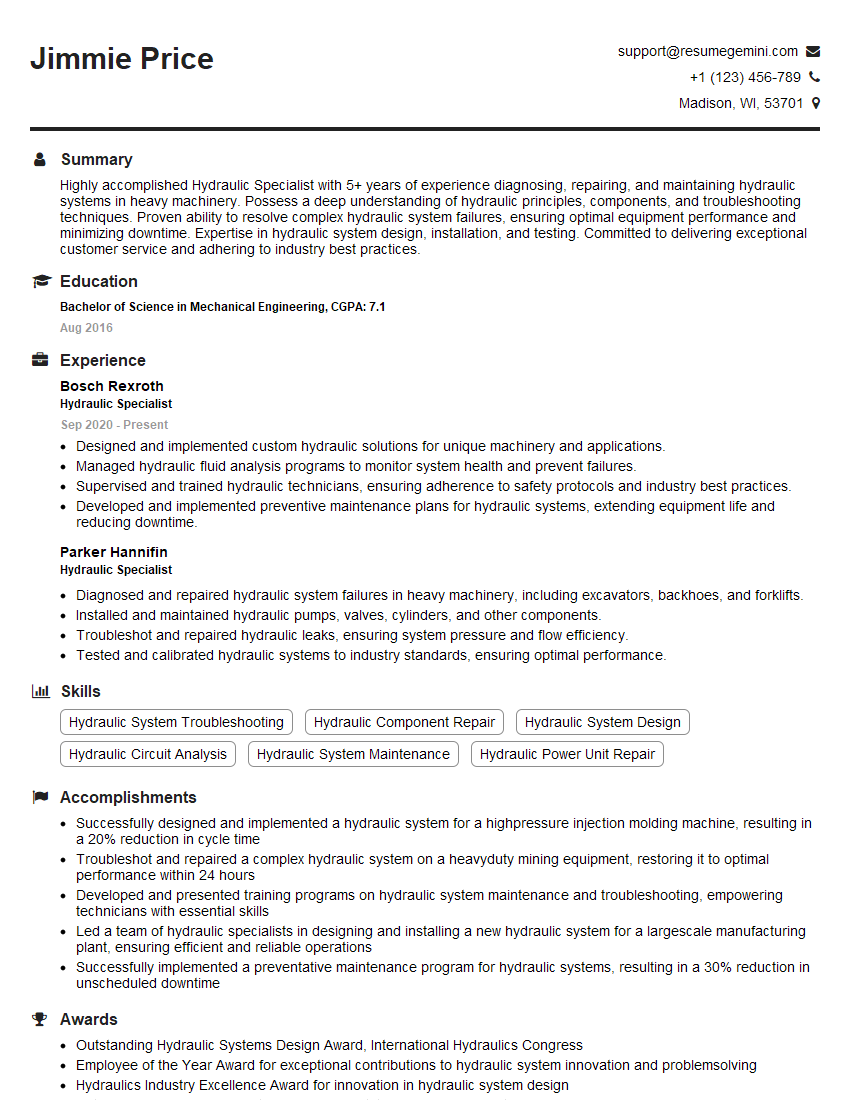

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hydraulic Specialist

1. Describe the components and working principle of a hydraulic system.

- Components include pumps, reservoirs, filters, valves, cylinders, and hoses.

- The pump creates pressure in the fluid, which is then transferred to the cylinders to create motion.

- Valves control the flow of fluid, while filters remove impurities.

- The reservoir stores the fluid and provides a cooling effect.

- Hoses connect the components and allow for flexibility.

2. Explain the different types of hydraulic pumps and their applications.

Positive Displacement Pumps

- Fixed displacement pumps: Provide constant flow regardless of pressure.

- Variable displacement pumps: Adjust flow to meet system demands.

Non-Positive Displacement Pumps

- Centrifugal pumps: Create pressure by centrifugal force.

- Gear pumps: Use gears to trap and move fluid.

Applications

- Fixed displacement pumps: Heavy machinery, construction equipment.

- Variable displacement pumps: Mobile hydraulic systems, industrial machinery.

- Centrifugal pumps: Pumping water, irrigation systems.

- Gear pumps: Dispensing systems, lubrication systems.

3. Discuss the importance of hydraulic fluid selection and maintenance.

- Selection factors: Viscosity, cleanliness, compatibility with system components.

- Maintenance includes regular fluid changes, filtration, and analysis.

- Clean fluid reduces wear, corrosion, and contamination.

- Proper maintenance extends system life and reliability.

4. Describe the operation and maintenance of hydraulic valves.

Operation

- Directional control valves: Change the direction of fluid flow.

- Pressure control valves: Regulate pressure in the system.

- Flow control valves: Control the flow rate of fluid.

Maintenance

- Regular cleaning and inspection.

- Replacement of worn or damaged parts.

- Calibration to ensure proper operation.

5. Explain the principles of hydraulic circuit design.

- Consider flow rate, pressure, and component selection.

- Optimize component placement and routing for efficiency.

- Design for maintainability and serviceability.

- Employ safety features such as pressure relief valves and filters.

6. Discuss the troubleshooting techniques for hydraulic systems.

- Visual inspection for leaks or loose connections.

- Pressure readings to identify pressure drops or spikes.

- Flow measurements to diagnose flow restrictions.

- Electrical testing for valve or pump faults.

7. Describe the safety precautions when working with hydraulic systems.

- Wear appropriate personal protective equipment.

- Inspect systems before operation.

- Release pressure before performing maintenance.

- Never work on a live system.

- Follow proper lockout/tagout procedures.

8. Discuss the emerging trends and technologies in hydraulic systems.

- Electro-hydraulic systems: Combining hydraulics with electronics for improved control.

- Energy-efficient pumps and components.

- Bio-based hydraulic fluids for environmental sustainability.

- Remote monitoring and diagnostics using IoT.

- Integration of artificial intelligence for predictive maintenance.

9. Explain your approach to hydraulic system design and analysis.

- Gather requirements and analyze system parameters.

- Develop design concepts and perform simulations.

- Select components based on performance and reliability.

- Analyze system behavior under various operating conditions.

- Optimize design for efficiency, maintainability, and cost.

10. Discuss your experience in working with different types of hydraulic systems.

- Provide specific examples of systems you have worked on.

- Highlight your contributions and successes.

- Demonstrate your knowledge of various hydraulic components and applications.

- Emphasize your ability to troubleshoot and resolve system issues.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hydraulic Specialist.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hydraulic Specialist‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Hydraulic specialists are responsible for designing, developing, and maintaining hydraulic systems, which are used in a wide variety of industries, including construction, manufacturing, and transportation. The key job responsibilities of a hydraulic specialist include:

1. Design and Develop Hydraulic Systems

Hydraulic specialists design and develop hydraulic systems that are used to power and control machinery and equipment. They work with engineers and other specialists to determine the requirements of the system and then design and develop a system that meets those requirements. Hydraulic specialists may also be responsible for developing new hydraulic components and technologies.

- Designing and developing hydraulic systems for new and existing machinery and equipment.

- Calculating and specifying the flow rate, pressure, and other operating parameters of hydraulic systems.

- Selecting and installing hydraulic components, such as pumps, valves, hoses, and fittings.

2. Maintain and Repair Hydraulic Systems

Hydraulic specialists maintain and repair hydraulic systems to ensure that they operate safely and efficiently. They troubleshoot problems with hydraulic systems and make repairs as needed. Hydraulic specialists may also be responsible for training other employees on how to operate and maintain hydraulic systems.

- Troubleshooting and repairing hydraulic systems.

- Replacing worn or damaged hydraulic components.

- Testing and calibrating hydraulic systems to ensure that they meet specifications.

3. Provide Technical Support

Hydraulic specialists provide technical support to customers and other employees. They answer questions about hydraulic systems and provide advice on how to operate and maintain them. Hydraulic specialists may also develop training materials and conduct training sessions on hydraulic systems.

- Providing technical support to customers and other employees.

- Answering questions about hydraulic systems.

- Developing training materials and conducting training sessions on hydraulic systems.

4. Stay Up-to-Date on Hydraulic Technology

Hydraulic specialists stay up-to-date on hydraulic technology. They read trade journals, attend conferences, and take continuing education courses. Hydraulic specialists also work with manufacturers to learn about new hydraulic products and technologies.

- Reading trade journals and attending conferences to stay up-to-date on hydraulic technology.

- Taking continuing education courses to learn about new hydraulic products and technologies.

- Working with manufacturers to learn about new hydraulic products and technologies.

Interview Tips

In order to ace an interview for a hydraulic specialist position, it is important to be prepared. Here are a few tips to help you prepare for your interview:

1. Research the Company and the Position

Before you go on an interview, it is important to research the company and the position. This will help you to understand the company’s culture and the specific requirements of the position. You can research the company on its website, LinkedIn, and other online sources. You can also research the position by reading the job description and talking to people who work in the field.

- Visit the company’s website and LinkedIn page.

- Read the job description carefully.

- Talk to people who work in the hydraulics field.

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you may be asked during an interview for a hydraulic specialist position. It is important to practice answering these questions so that you can give confident and well-thought-out answers. Some common interview questions include:

- Tell me about your experience with hydraulic systems.

- What are your strengths and weaknesses as a hydraulic specialist?

- Why are you interested in this position?

- What are your career goals?

- Do you have any questions for me?

3. Dress Professionally and Arrive on Time

It is important to dress professionally and arrive on time for your interview. This will show the interviewer that you are serious about the position and that you respect their time. When you arrive for your interview, be sure to greet the interviewer with a firm handshake and make eye contact.

- Dress in a suit or business casual attire.

- Arrive on time for your interview.

- Greet the interviewer with a firm handshake and make eye contact.

4. Be Yourself and Be Confident

The most important thing is to be yourself and be confident during your interview. The interviewer wants to get to know you and learn about your skills and experience. Be honest and upfront about your strengths and weaknesses, and be confident in your abilities. If you are prepared and confident, you will be more likely to make a good impression on the interviewer and land the job.

- Be honest and upfront about your strengths and weaknesses.

- Be confident in your abilities.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Hydraulic Specialist interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.