Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Hydraulic Tester position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

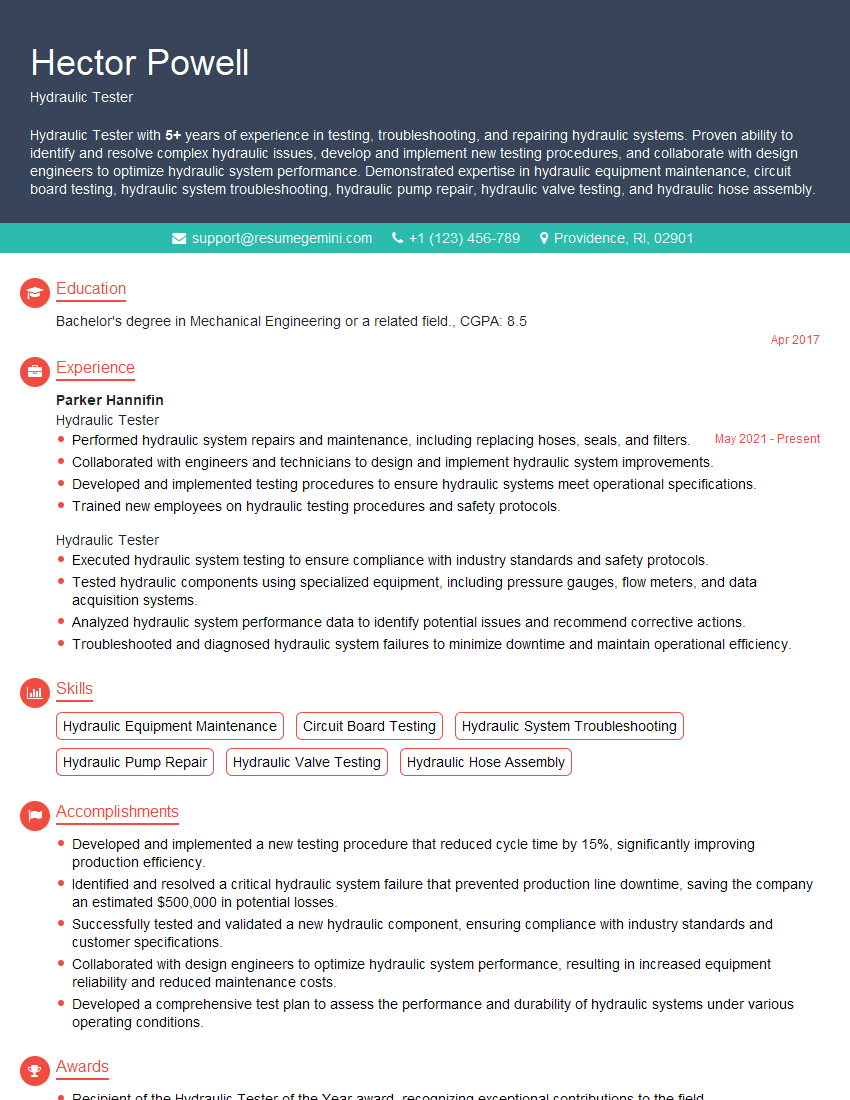

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hydraulic Tester

1. Explain the principles of hydraulic pressure testing?

Hydraulic pressure testing is a non-destructive testing method used to verify the integrity of pressure vessels, piping systems, and other components that are designed to withstand internal pressure. The test involves applying a hydraulic fluid to the component at a pressure that exceeds the intended operating pressure, and then monitoring the component for any leaks or deformations.

- The key principles of hydraulic pressure testing include:

- The application of a known pressure to the component under test

- The monitoring of the component for any leaks or deformations

- The comparison of the test results to acceptance criteria

2. What are the different types of hydraulic pressure testing methods and when would you use each one?

Hydrostatic testing

- Hydrostatic testing is the most common type of hydraulic pressure testing, and it involves filling the component with water and then applying pressure.

- Hydrostatic testing is used to test the integrity of pressure vessels, piping systems, and other components that are designed to withstand internal pressure.

Pneumatic testing

- Pneumatic testing involves filling the component with air or another gas and then applying pressure.

- Pneumatic testing is used to test the integrity of components that are not designed to withstand high internal pressures, such as plastic pipes and hoses.

3. What are the safety precautions that must be taken when performing hydraulic pressure testing?

- Hydraulic pressure testing can be dangerous if proper safety precautions are not taken. Some of the most important safety precautions include:

- Wearing appropriate personal protective equipment, such as safety glasses, gloves, and a hard hat

- Using a pressure gauge that is calibrated and in good working order

- Ensuring that the component under test is properly supported and restrained

- Bleeding off the pressure slowly and carefully after the test is complete

4. What are the most common defects that you have encountered during hydraulic pressure testing?

- The most common defects that I have encountered during hydraulic pressure testing include:

- Leaks

- Deformations

- Cracks

5. What is the difference between a proof pressure test and a burst pressure test?

- A proof pressure test is a type of hydraulic pressure test that is used to verify the integrity of a component at a pressure that is less than the component’s burst pressure.

- A burst pressure test is a type of hydraulic pressure test that is used to determine the burst pressure of a component.

6. What are the advantages and disadvantages of using hydraulic pressure testing?

Advantages

- Hydraulic pressure testing is a non-destructive testing method

- Hydraulic pressure testing can be used to test a wide range of components

- Hydraulic pressure testing is a relatively simple and inexpensive testing method

Disadvantages

- Hydraulic pressure testing can be dangerous if proper safety precautions are not taken

- Hydraulic pressure testing can take a long time to complete

7. What is the difference between a hydraulic pressure test and a leak test?

- A hydraulic pressure test is a type of non-destructive testing that is used to verify the integrity of a component at a pressure that is less than the component’s burst pressure.

- A leak test is a type of non-destructive testing that is used to detect leaks in a component.

8. What are the different types of hydraulic pressure testing equipment?

- The different types of hydraulic pressure testing equipment include:

- Pressure pumps

- Pressure gauges

- Test fixtures

9. What are the latest trends in hydraulic pressure testing?

- Some of the latest trends in hydraulic pressure testing include:

- The use of automated testing systems

- The use of non-destructive testing methods to detect leaks

- The use of computer modeling to simulate hydraulic pressure testing

10. How do you stay up-to-date on the latest trends in hydraulic pressure testing?

- I stay up-to-date on the latest trends in hydraulic pressure testing by reading industry publications, attending conferences, and networking with other professionals in the field.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hydraulic Tester.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hydraulic Tester‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Hydraulic Testers play a critical role in ensuring the integrity and efficiency of hydraulic systems. Their primary responsibilities include:

1. Testing and Evaluation

Conduct comprehensive testing and evaluation of hydraulic components, assemblies, and systems.

- Utilize specialized equipment and techniques to measure pressure, flow rate, leakage, and other performance parameters.

- Analyze test results and assess the conformity of components and systems to specifications.

2. Troubleshooting and Diagnosis

Diagnose malfunctions and identify the root causes of hydraulic system failures.

- Conduct visual inspections, perform pressure checks, and analyze system behavior to pinpoint problem areas.

- Develop and implement corrective actions to restore optimal system performance.

3. Equipment Maintenance and Calibration

Maintain and calibrate hydraulic testing equipment to ensure accuracy and reliability.

- Perform routine maintenance, such as cleaning, lubrication, and component replacement.

- Calibrate pressure gauges, flow meters, and other testing instruments against certified standards.

4. Report Generation and Documentation

Prepare detailed reports and documentation on hydraulic system testing and evaluation.

- Record test data, observations, and analysis results accurately.

- Generate technical reports that provide clear and concise summaries of findings.

Interview Tips

To ace the interview for a Hydraulic Tester position, candidates should:

1. Research the Industry and Company

Familiarize themselves with the latest hydraulic technologies, industry standards, and best practices.

- Attend industry events, read trade publications, and network with professionals in the field.

- Research the company’s products, services, and reputation in the industry.

2. Highlight Relevant Skills and Experience

Emphasize their technical skills in hydraulic testing, as well as their problem-solving and analytical abilities.

- Use specific examples from their work experience where they have successfully tested and diagnosed hydraulic systems.

- Quantify their accomplishments whenever possible to demonstrate their impact on system performance.

3. Practice Common Interview Questions

Prepare for common interview questions related to hydraulic testing, troubleshooting, and system maintenance.

- Example Outline:

- Question: Describe your experience in testing hydraulic components for leakage.

- Answer: In my previous role, I developed a customized test procedure using a pressure intensifier and helium leak detector. This enabled us to detect leaks as small as 1 cubic centimeter per minute.

4. Ask Thoughtful Questions

Ask intelligent questions about the company’s hydraulic systems, testing protocols, and career development opportunities.

- This demonstrates their interest in the position and their commitment to continuous learning.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Hydraulic Tester, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Hydraulic Tester positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.