Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Hydro-Pneumatic Tester position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

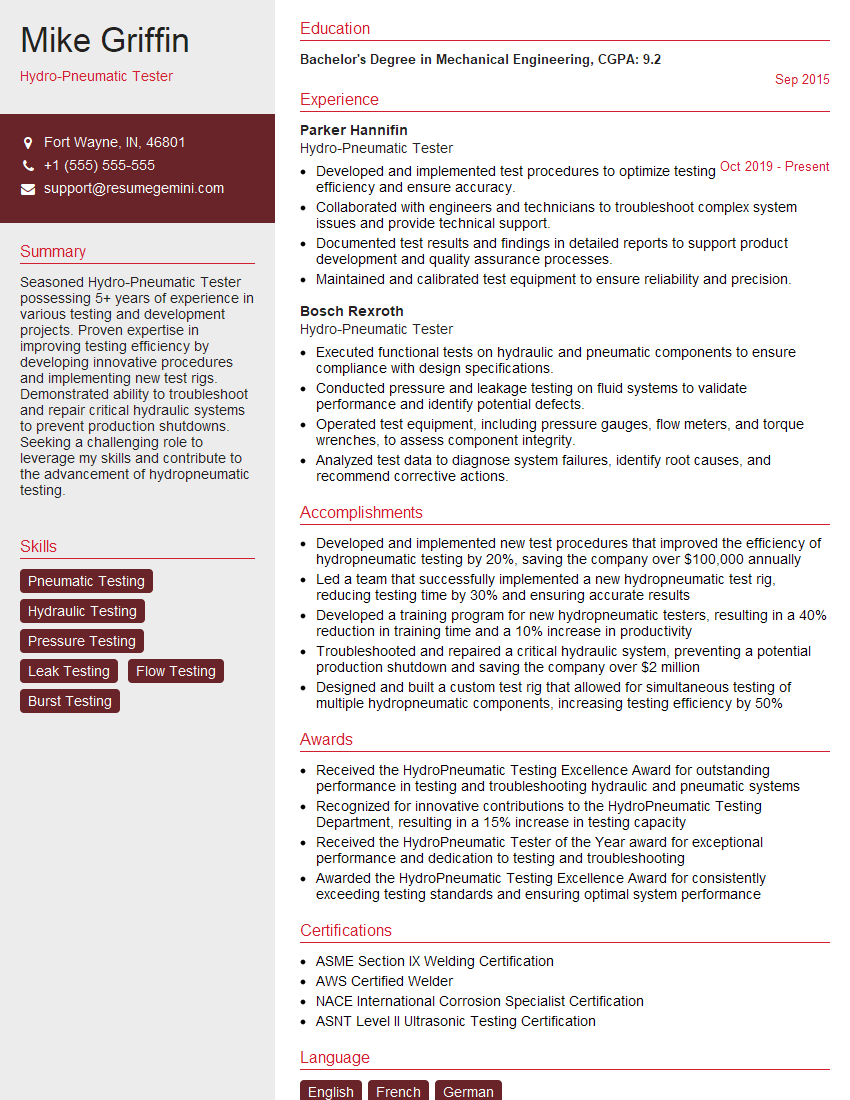

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hydro-Pneumatic Tester

1. Describe the principles of hydro-pneumatic testing?

Hydro-pneumatic testing involves applying both water and air pressure to test the integrity of a component or system. It combines the advantages of both hydrostatic (water pressure) and pneumatic (air pressure) testing methods, providing a more comprehensive and accurate assessment of a component’s performance and reliability.

- Water pressure: Used to simulate real-life operating conditions and detect leaks, weak points, and other defects. It can identify areas where water can penetrate, such as cracks or flaws, and assess the component’s ability to withstand fluid pressure.

- Air pressure: Used to pressurize the component from the inside, allowing for detection of leaks, airflow blockages, and other issues that may not be apparent during hydrostatic testing alone. It also helps verify the component’s ability to handle both internal and external pressures.

2. Explain the different types of hydro-pneumatic tests?

There are several types of hydro-pneumatic tests, each designed to assess different aspects of a component’s performance and integrity.

Leak testing:

- Detects leaks in components, systems, and seals by applying a combination of water and air pressure.

- Identifies points where fluid or air can escape, indicating potential defects or areas of concern.

Strength testing:

- Assesses the structural integrity and strength of a component under extreme pressure conditions.

- Evaluates the component’s ability to withstand both internal and external forces without failing.

Functional testing:

- Tests the functionality of a component or system by simulating real-world operating conditions.

- Verifies the component’s performance, efficiency, and reliability under various pressure and flow conditions.

3. Describe the equipment used in hydro-pneumatic testing?

Hydro-pneumatic testing requires specialized equipment to generate and control both water and air pressure, as well as monitor and measure the results.

- Pressure source: Provides a regulated supply of water and air pressure, typically using pumps or compressors.

- Pressure regulators: Control and maintain the desired pressure levels for both water and air.

- Test chamber: Encloses the component under test and can withstand the applied pressure.

- Sensors and transducers: Monitor pressure, flow, and other parameters during the test.

- Data acquisition system: Records and displays test data for analysis and reporting.

4. What are the safety considerations in hydro-pneumatic testing?

Hydro-pneumatic testing involves working with high-pressure systems, so safety is paramount.

- Proper training: All personnel involved in testing must be trained in the safe operation of the equipment and testing procedures.

- Personal protective equipment (PPE): Wear appropriate PPE, including safety glasses, gloves, and hearing protection.

- Pressure containment: Ensure that all pressure vessels and test chambers are properly rated and maintained to prevent ruptures.

- Pressure release procedures: Establish clear procedures for releasing pressure safely and gradually after testing.

- Emergency response plan: Have an emergency response plan in place to address any potential incidents or accidents.

5. What are the advantages of hydro-pneumatic testing over other testing methods?

Hydro-pneumatic testing offers several advantages over other testing methods.

- Comprehensive assessment: Combines the benefits of both hydrostatic and pneumatic testing, providing a more thorough evaluation of a component’s performance and integrity.

- Leak detection: Highly effective in identifying leaks and weak points that may not be detectable using other methods.

- Strength testing: Can assess the component’s ability to withstand both internal and external pressure, ensuring structural integrity.

- Functional testing: Simulates real-world operating conditions, verifying the component’s functionality and reliability under various pressure and flow scenarios.

6. What are the challenges in hydro-pneumatic testing?

Hydro-pneumatic testing presents certain challenges that need to be addressed.

- Test fixture design: Designing test fixtures that can withstand high pressure and accommodate different component shapes and sizes can be complex.

- Pressure control: Maintaining precise and stable pressure levels during testing is crucial to obtain accurate and reliable results.

- Data interpretation: Analyzing and interpreting test results requires expertise and experience to identify potential issues and make informed decisions.

- Safety concerns: Working with high-pressure systems requires strict adherence to safety protocols and regular maintenance of equipment.

7. How do you ensure the accuracy of hydro-pneumatic test results?

Ensuring the accuracy of hydro-pneumatic test results is critical for reliable assessment.

- Calibration: Regularly calibrate all pressure gauges, sensors, and other measurement equipment used during testing.

- Test procedure standardization: Establish standardized test procedures and follow them consistently to minimize variability.

- Proper training: Train personnel on the correct use of equipment and testing procedures to ensure accurate data collection.

- Data validation: Review and validate test data to identify any anomalies or inconsistencies that may affect accuracy.

8. Describe your experience in troubleshooting hydro-pneumatic testing issues?

Troubleshooting hydro-pneumatic testing issues requires a combination of technical knowledge and problem-solving skills.

- Pressure leaks: Identify and seal any leaks in the test fixture, pressure lines, or component under test.

- Pressure fluctuations: Investigate the pressure source and regulator to ensure stable pressure levels.

- Sensor malfunctions: Check sensor calibration, wiring, and connections to ensure accurate pressure readings.

- Data acquisition errors: Verify the data acquisition system and software for any issues that may affect data recording and analysis.

9. How do you stay up to date with the latest hydro-pneumatic testing techniques?

Staying up-to-date with the latest hydro-pneumatic testing techniques is essential for continuous improvement.

- Industry conferences and workshops: Attend industry events to learn about new testing methods and advancements.

- Technical journals and publications: Read research papers and articles to stay informed about cutting-edge testing techniques.

- Manufacturer training: Participate in training sessions offered by manufacturers of hydro-pneumatic testing equipment.

- Online resources: Utilize online forums and discussion groups to connect with other professionals and exchange knowledge.

10. What are your career goals in the field of hydro-pneumatic testing?

Setting career goals provides direction and motivation for professional development.

- Technical expertise: Enhance my technical knowledge and skills in hydro-pneumatic testing, becoming an expert in the field.

- Problem-solving: Develop advanced problem-solving abilities to effectively troubleshoot and resolve complex testing issues.

- Team collaboration: Foster strong teamwork and collaboration skills to contribute to successful testing projects.

- Leadership: Aim to lead and mentor junior engineers, sharing knowledge and guiding their professional growth.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hydro-Pneumatic Tester.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hydro-Pneumatic Tester‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Hydro-Pneumatic Testers are responsible for the safe and efficient operation of hydro-pneumatic test systems. They ensure that the systems are maintained in accordance with applicable regulations and that all tests are performed to the required standards.

1. Conduct Hydro-Pneumatic Tests

- Perform hydro-pneumatic tests on a variety of components, including pipelines, pressure vessels, and hydraulic systems.

- Follow established procedures to ensure that tests are conducted safely and accurately.

- Record and interpret test results to identify any defects or failures.

2. Maintain Hydro-Pneumatic Test Systems

- Perform regular maintenance on hydro-pneumatic test systems, including cleaning, lubrication, and calibration.

- Troubleshoot and repair any problems that arise with the systems.

- Keep detailed records of all maintenance and repairs performed.

3. Monitor Test Data

- Monitor test data to ensure that tests are being performed to the required standards.

- Identify any trends or patterns in the data that may indicate potential problems.

- Report any anomalies or concerns to the supervisor.

4. Comply with Regulations

- Ensure that all hydro-pneumatic tests are conducted in accordance with applicable regulations.

- Maintain detailed records of all tests performed.

- Report any non-conformances to the supervisor.

Interview Tips

To ace an interview for a Hydro-Pneumatic Tester position, it is important to be well-prepared and to have a clear understanding of the key job responsibilities. Here are some tips to help you prepare for the interview:

1. Research the Company and the Position

- Visit the company’s website to learn more about their business, products, and services.

- Read the job description carefully and make sure that you understand the key requirements of the position.

- Identify any specific skills or experience that the company is looking for that you may have.

2. Prepare Your Answers to Common Interview Questions

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What is your experience with hydro-pneumatic testing?

- How do you stay up-to-date on the latest industry trends in hydro-pneumatic testing?

3. Be Enthusiastic and Professional

- Be polite and respectful to the interviewer and other employees.

- Dress professionally and make eye contact.

- Be positive and enthusiastic about the opportunity to work for the company.

4. Ask Questions

- Ask thoughtful questions about the position and the company at the end of the interview.

- This shows that you are interested in the role and that you are genuinely curious about the company.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Hydro-Pneumatic Tester, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Hydro-Pneumatic Tester positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.