Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Hydrogen Plant Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Hydrogen Plant Operator so you can tailor your answers to impress potential employers.

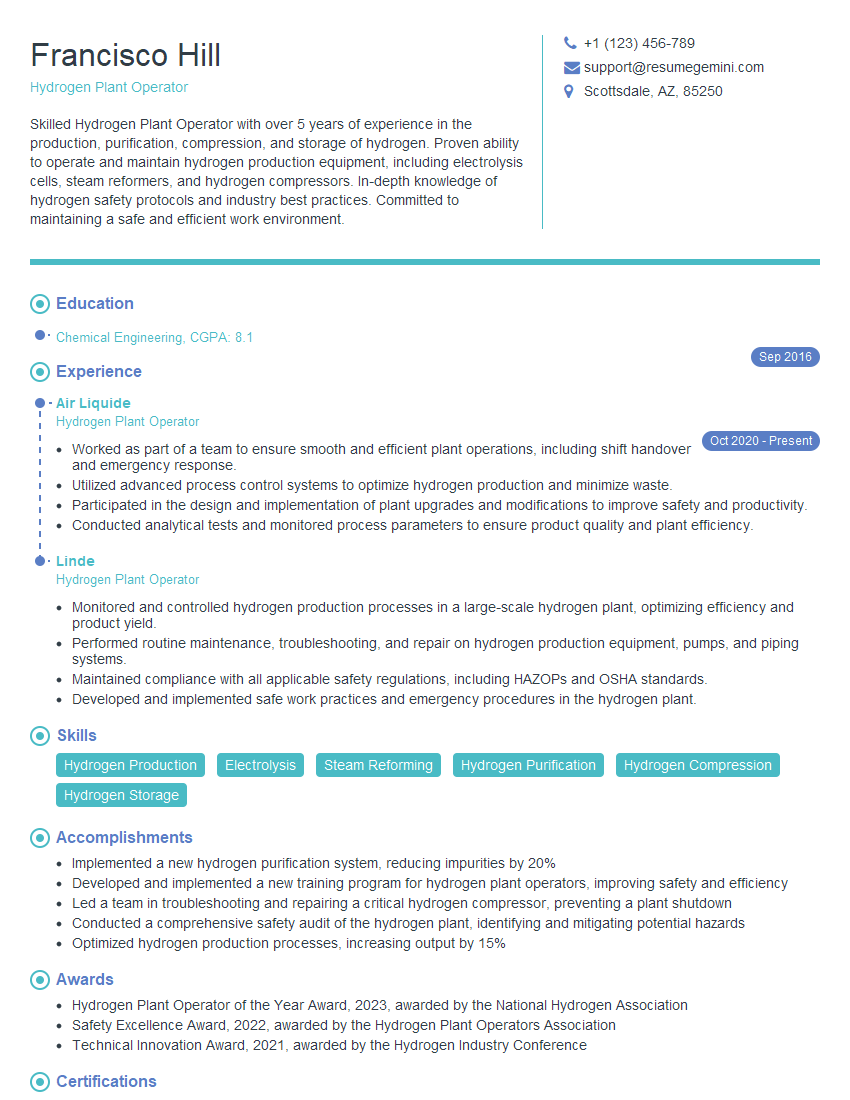

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hydrogen Plant Operator

1. Explain the process of hydrogen production in a hydrogen plant.

Sure, the process of hydrogen production in a hydrogen plant can be summarized as follows:

- Water treatment: Raw water is purified to remove impurities and dissolved solids.

- Electrolysis: Purified water is subjected to an electric current in an electrolyzer, splitting it into hydrogen and oxygen.

- Gas separation: Hydrogen gas is separated from oxygen gas using a variety of methods, such as pressure swing adsorption.

- Compression and storage: Hydrogen gas is compressed and stored in high-pressure vessels or pipelines for transportation and distribution.

2. Describe the key components of a hydrogen plant and their functions.

Electrolyzer

- Converts water into hydrogen and oxygen through electrolysis.

- Comprises a cathode, anode, and electrolyte (usually water with an alkaline or acidic solution).

Separator

- Separates hydrogen from oxygen using techniques like pressure swing adsorption or membrane separation.

- Ensures high-purity hydrogen production.

Compressor

- Compresses hydrogen gas to facilitate storage and transportation.

- Increases hydrogen density, reducing storage volume.

3. Discuss the safety hazards associated with hydrogen production and storage.

- Flammability: Hydrogen gas is highly flammable, requiring strict adherence to safety protocols.

- High pressure: Hydrogen is often stored and transported under high pressure, presenting potential hazards.

- Leakage: Hydrogen leaks can lead to explosions or fires, emphasizing the importance of leak detection systems.

- Embrittlement: Hydrogen can cause embrittlement of certain metals, affecting equipment integrity.

4. Describe the different types of electrolyzers used in hydrogen production.

- Alkaline Electrolyzer (AEL): Utilizes an alkaline electrolyte (potassium hydroxide), has relatively low efficiency but high durability.

- Proton Exchange Membrane (PEM) Electrolyzer: Employs a solid polymer membrane as an electrolyte, offers higher efficiency but requires purer water.

- Solid Oxide Electrolyzer (SOE): Operates at high temperatures, uses a ceramic electrolyte, and achieves high efficiency but requires specialized materials.

5. Explain the factors that affect the efficiency of a hydrogen plant.

- Electrolyzer efficiency: Determined by factors like cell design, operating temperature, and catalyst activity.

- Power source: The efficiency of the electricity generation process used to power the electrolyzer.

- Plant design: Optimal plant design minimizes energy losses and ensures efficient gas separation and compression.

- Operating conditions: Temperature, pressure, and flow rates can impact the efficiency of the hydrogen production process.

6. Discuss the environmental benefits of using hydrogen as a fuel.

- Zero emissions: Hydrogen combustion produces only water, reducing greenhouse gas emissions and air pollution.

- Renewable energy source: Hydrogen can be produced from renewable sources like solar and wind power, promoting sustainability.

- Energy storage: Hydrogen can store energy from intermittent renewable sources, enabling grid flexibility and decarbonization.

7. Describe the challenges in the transportation and storage of hydrogen.

- Hydrogen embrittlement: Hydrogen can weaken certain metals, requiring specialized materials for transportation and storage.

- Low volumetric energy density: Hydrogen has a low volumetric energy density, necessitating high-pressure storage or liquefaction.

- Leakage: Hydrogen is a small molecule that can easily leak through materials, requiring robust containment systems.

8. Explain the importance of quality control in hydrogen production.

- Purity: Ensuring hydrogen purity meets industry standards and customer specifications.

- Safety: Detecting and preventing impurities that could pose safety hazards.

- Efficiency: Optimizing plant performance by controlling impurities that affect electrolyzer efficiency.

9. Describe the maintenance procedures for hydrogen plant equipment.

- Electrolyzer maintenance: Regular cleaning, replacement of electrodes, and monitoring of electrolyte levels.

- Separator maintenance: Inspection, cleaning, and replacement of membranes or adsorbent materials.

- Compressor maintenance: Lubrication, filter changes, and vibration monitoring.

- Storage tank maintenance: Pressure testing, leak detection, and corrosion protection.

10. Discuss the future prospects of hydrogen production and its role in the energy transition.

- Growing demand: Increasing adoption of hydrogen fuel cell vehicles, industrial applications, and energy storage.

- Cost reduction: Technological advancements and economies of scale are expected to lower hydrogen production costs.

- Infrastructure development: Investments in hydrogen refueling stations and pipelines are crucial for widespread adoption.

- Policy support: Government incentives and regulations can accelerate the transition to hydrogen-based energy systems.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hydrogen Plant Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hydrogen Plant Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Hydrogen Plant Operator is accountable for the safe and efficient operation of a hydrogen production plant, ensuring compliance with all safety protocols and regulatory standards. Key responsibilities include:

1. Plant Operations and Monitoring

Monitor and control all aspects of hydrogen production, including pressure, temperature, flow rates, and equipment performance.

- Operate and maintain hydrogen production equipment, including compressors, heat exchangers, and purification systems.

- Adjust process parameters to optimize hydrogen production efficiency and meet quality specifications.

- Conduct routine inspections and maintenance on equipment to prevent breakdowns and ensure smooth operation.

2. Safety and Compliance

Ensure strict adherence to safety regulations and procedures to prevent accidents or environmental hazards.

- Follow established safety protocols for handling hydrogen and other hazardous materials.

- Conduct regular safety inspections and audits to identify and mitigate potential risks.

- Stay abreast of industry best practices and regulatory updates to ensure compliance with applicable standards.

3. Troubleshooting and Problem-Solving

Quickly identify and resolve operational issues to minimize downtime and maintain production targets.

- Diagnose and troubleshoot equipment malfunctions and process deviations.

- Implement corrective actions and adjustments to restore operations to optimal levels.

- Document and report any incidents or deviations from standard operating procedures.

4. Communication and Reporting

Effectively communicate with supervisors, technicians, and other stakeholders.

- Provide regular status updates on plant operations and any deviations from normal conditions.

- Prepare and maintain accurate records and reports related to production, safety, and maintenance.

- Participate in training and development programs to enhance knowledge and skills.

Interview Preparation Tips

To ace an interview for a Hydrogen Plant Operator position, consider the following tips:

1. Research the Company and Industry

Thoroughly research the company and the hydrogen industry to demonstrate your understanding of their business and current trends.

- Review the company’s website, annual reports, and news articles to gain insights into their operations, values, and future plans.

- Keep abreast of industry advancements and best practices related to hydrogen production and safety.

2. Highlight Relevant Skills and Experience

Emphasize your technical expertise in hydrogen plant operations, safety protocols, and troubleshooting.

- Quantify your experience with specific examples of how you have successfully managed hydrogen production processes.

- Highlight your knowledge of safety regulations and your ability to identify and mitigate risks.

- Share instances where you have effectively resolved operational issues and implemented corrective actions.

3. Prepare for Technical Questions

Anticipate technical questions related to hydrogen production, equipment operation, and safety procedures.

- Review the principles of hydrogen production, including electrolysis, steam reforming, and water gas shift reaction.

- Familiarize yourself with the different types of hydrogen production equipment and their functions.

- Study safety regulations and best practices for handling hydrogen and other hazardous materials.

4. Practice Your STAR Method Answers

Use the STAR method (Situation, Task, Action, Result) to prepare concise and effective answers to interview questions.

- Describe a specific situation or task that highlights your relevant skills and experience.

- Explain the actions you took to address the situation or complete the task.

- Quantify the results of your actions and how they benefited the organization.

5. Dress Professionally and Arrive On Time

Make a positive first impression by dressing professionally and arriving on time for your interview.

- Choose business attire that is clean, pressed, and appropriate for the industry.

- Plan your route in advance to ensure you arrive on time and avoid any unforeseen delays.

Next Step:

Now that you’re armed with the knowledge of Hydrogen Plant Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Hydrogen Plant Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini