Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Hydropress Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

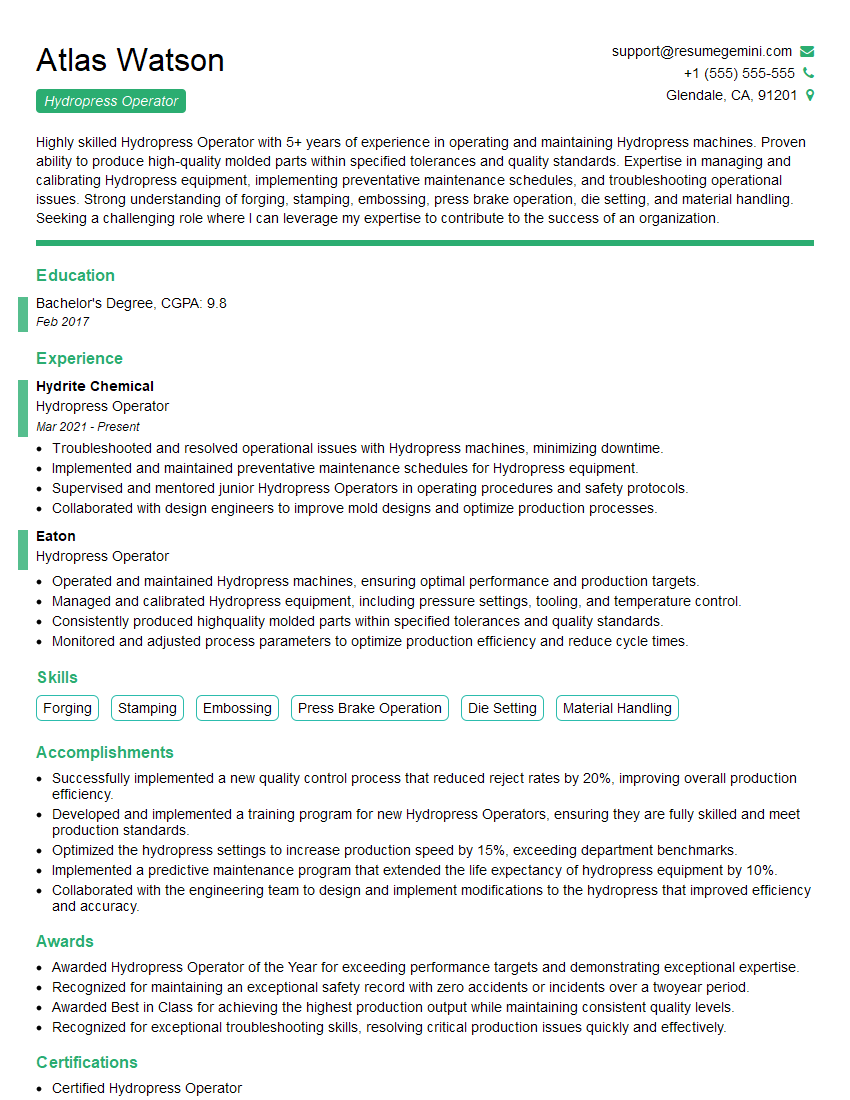

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hydropress Operator

1. Describe the key responsibilities of a Hydropress Operator.

As a Hydropress Operator, my primary responsibilities include operating and maintaining hydropresses, ensuring the safe and efficient production of parts and components.

- Operate hydropresses to shape and form metal materials using high-pressure hydraulic systems.

- Monitor and control press operations, adjusting pressure, temperature, and timing to achieve desired results.

- Inspect parts for dimensional accuracy and quality, ensuring compliance with specifications and customer requirements.

- Perform routine maintenance and troubleshooting on hydropresses, including cleaning, lubrication, and minor repairs.

- Adhere to established safety protocols, ensuring a safe work environment and compliance with industry regulations.

2. Explain the different types of hydropresses and their applications.

There are various types of hydropresses, each designed for specific applications.

Mechanical Hydropresses

- Use a mechanical linkage system to generate hydraulic pressure.

- Suitable for high-tonnage applications, such as forming large metal parts.

Hydraulic Hydropresses

- Utilize hydraulic pumps to generate pressure.

- Provide precise control over pressure and speed.

- Commonly used in applications requiring intricate forming and bending.

Pneumatic Hydropresses

- Employ compressed air to generate hydraulic pressure.

- Offer rapid cycling and are suitable for low-tonnage applications.

- Ideal for forming small parts and delicate materials.

3. Describe the safety precautions that must be taken when operating a hydropress.

Operating a hydropress requires strict adherence to safety protocols to prevent accidents and injuries.

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and protective clothing.

- Ensure the work area is clear of obstacles and tripping hazards.

- Inspect the hydropress before operation, checking for any damage or leaks.

- Follow established operating procedures and never exceed the rated capacity of the press.

- Use proper lifting techniques when handling heavy materials and always maintain a safe distance from the press when it is in operation.

4. How do you troubleshoot common hydropress problems?

Troubleshooting hydropress problems involves identifying the root cause and implementing appropriate solutions.

- Low pressure: Check hydraulic fluid levels, pump operation, and any leaks in the system.

- Inconsistent pressure: Verify pressure gauges and sensors, inspect for air leaks, and ensure the hydraulic system is properly calibrated.

- Part defects: Examine die alignment, inspect for worn or damaged tooling, and adjust press settings if necessary.

- Leaking hydraulic fluid: Locate the source of the leak, tighten loose fittings, replace seals or hoses, and check for any cracks in the system.

- Excessive noise or vibration: Listen for unusual sounds, check for loose parts, and ensure the press is properly lubricated.

5. Describe the process of setting up and operating a hydropress.

Setting up and operating a hydropress involves several key steps.

- Prepare the press: Clean the work area, inspect the press, and ensure all safety measures are in place.

- Install the tooling: Select the appropriate dies or tooling for the job and securely mount them on the press.

- Adjust press settings: Set the required pressure, speed, and stroke according to the material and part specifications.

- Position the material: Place the material to be formed in the correct position between the dies.

- Operate the press: Initiate the press cycle, monitoring pressure and temperature to ensure the desired results are achieved.

6. How do you maintain and calibrate a hydropress?

Regular maintenance and calibration are crucial for ensuring optimal performance and longevity of a hydropress.

Maintenance

- Inspect fluid levels and replace or top up as needed.

- Clean and lubricate moving parts.

- Check for leaks and tighten any loose fittings.

- Perform periodic inspections of dies and tooling for wear and damage.

Calibration

- Verify pressure gauges and sensors using a calibrated pressure source.

- Adjust press settings according to the calibration results.

- Maintain accurate records of calibration to ensure traceability.

7. How do you work with other team members in a production environment?

In a production environment, effective teamwork is essential for achieving productivity and quality goals.

- Communicate clearly with colleagues, sharing information and updates.

- Assist other team members when needed, providing support and collaboration.

- Share knowledge and expertise to improve overall team performance.

- Respect and value the contributions of others, fostering a positive and inclusive work atmosphere.

8. How do you manage your time and prioritize tasks in a busy production environment?

Time management and prioritization are critical in a fast-paced production environment.

- Create a daily or weekly schedule, outlining tasks and deadlines.

- Prioritize tasks based on urgency and importance.

- Use tools such as to-do lists and calendars to stay organized.

- Delegate tasks when appropriate to ensure efficient workload distribution.

- Communicate any potential delays or challenges to supervisors or team members.

9. How do you stay updated on the latest advancements and best practices in hydropress operation?

Continuous learning and staying abreast of industry trends are vital for professional growth.

- Attend industry conferences and workshops.

- Read technical journals and articles.

- Consult with experts and participate in online forums.

- Seek opportunities for training and development.

- Stay informed about new technologies and advancements in the field.

10. How do you ensure the quality of your work and meet production targets?

Quality assurance and meeting production targets are paramount in maintaining operational efficiency.

- Follow established quality control procedures and standards.

- Inspect parts regularly to ensure dimensional accuracy and compliance.

- Identify and address any potential quality issues promptly.

- Monitor production output and adjust processes as needed to meet targets.

- Collaborate with quality control personnel to ensure adherence to specifications.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hydropress Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hydropress Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Hydropress Operators are responsible for operating hydro presses, which are used to form and shape metal parts. They ensure that the press is operating correctly, and that the parts produced meet specifications. The key responsibilities of a Hydropress Operator include:

1. Operating the Hydropress

Hydropress Operators are responsible for setting up and operating the hydro press. This includes loading the press with metal blanks, setting the correct pressure and speed, and monitoring the press during operation. They must also be able to troubleshoot any problems that may occur with the press.

- Loading the press with metal blanks

- Setting the correct pressure and speed

- Monitoring the press during operation

- Troubleshooting any problems that may occur

2. Inspecting Parts

Hydropress Operators are responsible for inspecting the parts produced by the press. They check the parts for defects, such as cracks, scratches, or dents. They also measure the parts to ensure that they meet specifications.

- Checking the parts for defects

- Measuring the parts to ensure that they meet specifications

3. Maintaining the Hydropress

Hydropress Operators are responsible for maintaining the hydro press. This includes cleaning and lubricating the press, and replacing any worn or damaged parts. They also perform regular inspections to identify any potential problems.

- Cleaning and lubricating the press

- Replacing any worn or damaged parts

- Performing regular inspections

4. Following Safety Procedures

Hydropress Operators must follow all safety procedures when operating the hydro press. This includes wearing the proper safety gear, and following lockout/tagout procedures. They must also be aware of the potential hazards of working with hydro presses.

- Wearing the proper safety gear

- Following lockout/tagout procedures

- Being aware of the potential hazards of working with hydro presses

Interview Tips

To ace an interview for a Hydropress Operator position, candidates should be prepared to discuss their experience and qualifications, as well as their knowledge of hydro presses and safety procedures. Some tips for preparing for an interview for a Hydropress Operator position include:

1. Research the Company

Candidates should research the company they are interviewing for to learn about their products, services, and culture. This will help them to understand the company’s needs and how they can contribute to the team.

- Visit the company’s website

- Read articles about the company in the news

- Talk to people who work at the company

2. Practice Answering Interview Questions

Candidates should practice answering common interview questions, such as “Tell me about yourself” and “Why are you interested in this position?”. They should also be prepared to answer questions about their experience operating hydro presses and their knowledge of safety procedures.

- Write out your answers to common interview questions

- Practice answering your answers out loud

- Ask a friend or family member to practice interviewing you

3. Dress Professionally

Candidates should dress professionally for their interview. This means wearing a suit or business casual attire. They should also make sure to arrive on time for their interview and be prepared to shake the interviewer’s hand.

- Wear a suit or business casual attire

- Arrive on time for your interview

- Be prepared to shake the interviewer’s hand

4. Be Enthusiastic and Positive

Candidates should be enthusiastic and positive during their interview. They should show the interviewer that they are interested in the position and that they are confident in their abilities. They should also be prepared to talk about their accomplishments and how they can contribute to the team.

- Be enthusiastic and positive

- Show the interviewer that you are interested in the position

- Be confident in your abilities

- Talk about your accomplishments and how you can contribute to the team

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Hydropress Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!