Feeling lost in a sea of interview questions? Landed that dream interview for Ice Cream Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Ice Cream Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

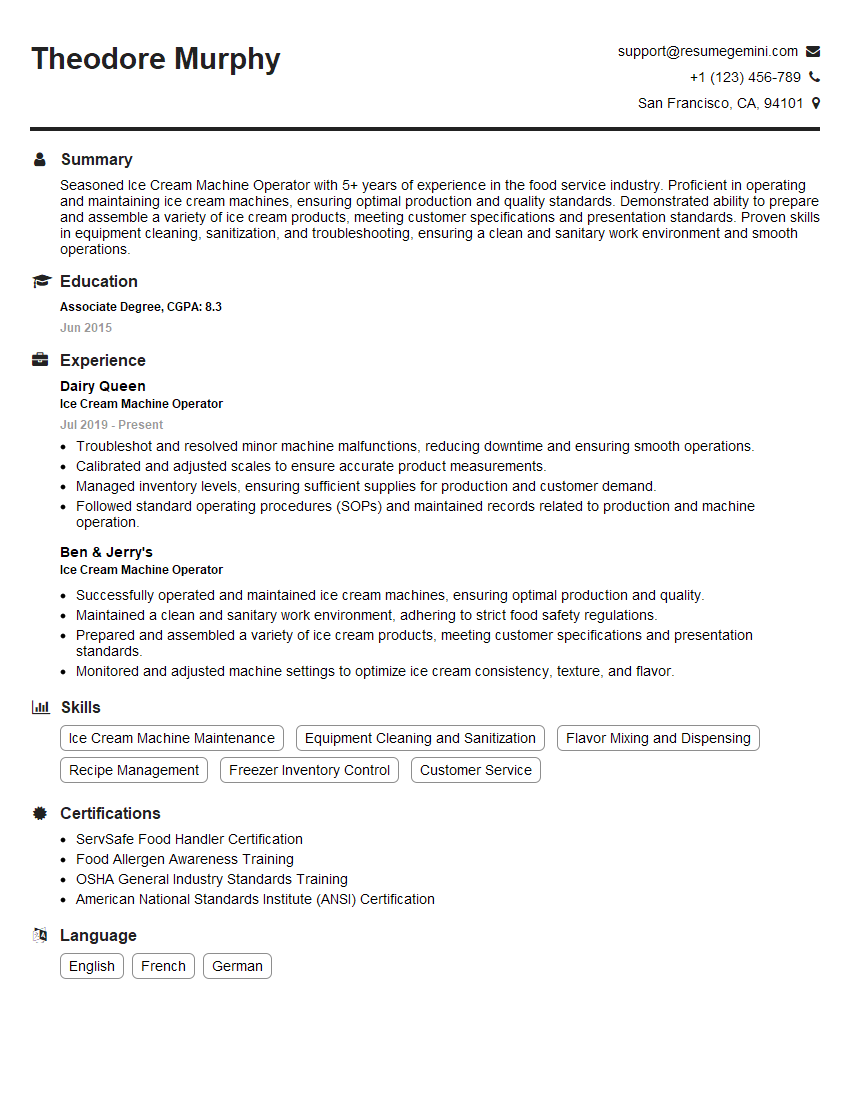

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ice Cream Machine Operator

1. What are the different types of ice cream machines, and how do they differ in terms of operation and maintenance?

Ice cream machines can be categorized into three main types:

- Batch freezers: These machines freeze the ice cream mix in a single batch, producing small quantities of ice cream. They require manual loading and unloading, and the freezing process can take several hours.

- Continuous freezers: These machines produce a continuous stream of ice cream, allowing for high-volume production. They are more automated than batch freezers and require less labor.

- Soft-serve machines: These machines produce a soft, creamy ice cream that is dispensed directly into a cone or cup. They typically have a smaller capacity than batch or continuous freezers and are used for quick-serve applications.

In terms of operation, batch freezers require more hands-on involvement, while continuous freezers and soft-serve machines are more automated. Maintenance needs also vary, with continuous freezers generally requiring more frequent servicing due to their complex mechanical systems.

2. Describe the process of preparing an ice cream mix, including the ingredients used and the steps involved.

- Ingredients: An ice cream mix typically consists of milk, cream, sugar, stabilizers, emulsifiers, and flavorings.

- Steps:

- Raw ingredients are combined and heated to dissolve the sugar and blend the components.

- The mixture is pasteurized to eliminate harmful bacteria.

- The mix is homogenized to create a smooth and stable emulsion.

- Flavorings, colorings, and other additives are incorporated.

- The mix is cooled and aged to allow the stabilizers to hydrate and the flavors to develop.

3. Explain how ice cream is frozen and aerated in an ice cream machine.

- Freezing: The ice cream mix is pumped into a freezing cylinder, where it is rapidly cooled by refrigerant circulating through the cylinder walls.

- Aeration: As the mix freezes, it is scraped by a rotating dasher, which incorporates air into the mixture. This aeration process gives ice cream its light and fluffy texture.

4. Describe the importance of proper sanitation and hygiene practices in ice cream production.

- To prevent contamination and ensure the safety of consumers.

- To maintain the quality and flavor of the ice cream.

- To comply with health regulations and avoid legal issues.

5. Explain how to troubleshoot common problems that may arise during ice cream machine operation, such as freezing issues or product quality defects.

- Freezing issues:

- Check the refrigerant levels and temperature settings.

- Inspect the dasher for damage or blockage.

- Verify that the mix is properly formulated and within the recommended temperature range.

- Product quality defects:

- Inadequate aeration can result in a dense or icy texture.

- Insufficient freezing can lead to a soft or runny consistency.

- Improper storage or handling can cause crystallization or flavor degradation.

6. Describe the different flavors and ingredients that can be used to create various types of ice cream.

- Flavors: From classic vanilla and chocolate to exotic fruits and unique combinations.

- Ingredients:

- Fruits and berries for fruity flavors.

- Nuts, candies, and cookies for added texture and flavor.

- Chocolate and cocoa for rich, indulgent flavors.

- Spices and extracts for unique and complex taste profiles.

7. Explain how to calculate the overrun of ice cream.

- Overrun: The amount of air incorporated into ice cream during freezing, expressed as a percentage.

- Formula: Overrun = (Volume of ice cream – Volume of mix) / Volume of mix x 100

- Optimal overrun: Typically between 80% and 120%, depending on the desired texture and quality.

8. Describe the process of hardening ice cream after it has been produced.

- Hardening chamber: Ice cream is placed in a freezer at a temperature of around -20°C (-4°F) or lower.

- Purpose:

- To complete the freezing process and stabilize the texture.

- To prevent the formation of large ice crystals.

- To allow the flavors to fully develop.

9. Explain how to properly clean and maintain an ice cream machine.

- Daily cleaning:

- Dismantle and wash all removable parts in hot, soapy water.

- Wipe down the exterior of the machine.

- Sanitize all surfaces that come into contact with the ice cream mix.

- Periodic maintenance:

- Inspect and lubricate moving parts.

- Check refrigerant levels and adjust as needed.

- Calibrate the machine to ensure accurate temperature control.

10. Describe any advancements or innovations in ice cream machine technology that you are aware of.

- Automated overrun control: Systems that automatically adjust the overrun to maintain a consistent texture.

- Energy-efficient models: Machines designed to reduce energy consumption without sacrificing performance.

- Smart machines: Machines that can be remotely monitored and controlled, providing real-time data and diagnostics.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ice Cream Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ice Cream Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Ice Cream Machine Operator is responsible for operating and maintaining ice cream making machines, ensuring the production of high-quality ice cream products.

1. Machine Operation

The operator must be able to:

- Prepare and load the machine with ice cream mix, flavors, and other ingredients.

- Control the machine’s settings to ensure optimal freezing and consistency.

- Monitor the machine’s performance and adjust settings as needed to maintain product quality.

- Maintain a clean and sanitized work area.

2. Production and Quality Control

The operator is accountable for:

- Producing ice cream according to established recipes and standards.

- Inspecting ice cream for quality and consistency.

- Identifying and resolving any production issues.

- Ensuring that products are labeled and packaged correctly.

3. Machine Maintenance

The operator is responsible for:

- Conducting daily cleaning and maintenance of the ice cream machine.

- Inspecting the machine for any wear or damage.

- Reporting any maintenance or repair needs to supervisors.

- Ensuring that the machine is always in good working condition.

4. Safety and Compliance

The operator must:

- Follow all safety procedures and guidelines.

- Wear appropriate personal protective equipment.

- Maintain a clean and organized work area.

- Comply with all applicable food safety regulations.

Interview Tips

To ace the interview for an Ice Cream Machine Operator position, follow these tips:

1. Research the Company and Position

Familiarize yourself with the company’s history, products, and values.

- Check the company’s website and social media pages.

- Read industry news and articles to gain insights into the company and its competitors.

2. Highlight Your Experience and Skills

Emphasize your previous experience in operating and maintaining ice cream machines.

- Provide specific examples of your responsibilities and accomplishments.

- Quantify your results whenever possible, using metrics such as production output or quality control measures.

3. Demonstrate Your Knowledge of Ice Cream Production

Discuss your understanding of the ice cream making process, including ingredients, freezing techniques, and quality control standards.

- Explain how you would troubleshoot common issues with ice cream machines.

- Share your ideas for improving production efficiency or quality.

4. Be Enthusiastic and Professional

Convey your passion for ice cream and your commitment to producing high-quality products.

- Be polite and respectful throughout the interview.

- Dress appropriately and arrive on time for your interview.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Ice Cream Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Ice Cream Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.