Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Ice Cream Maker interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Ice Cream Maker so you can tailor your answers to impress potential employers.

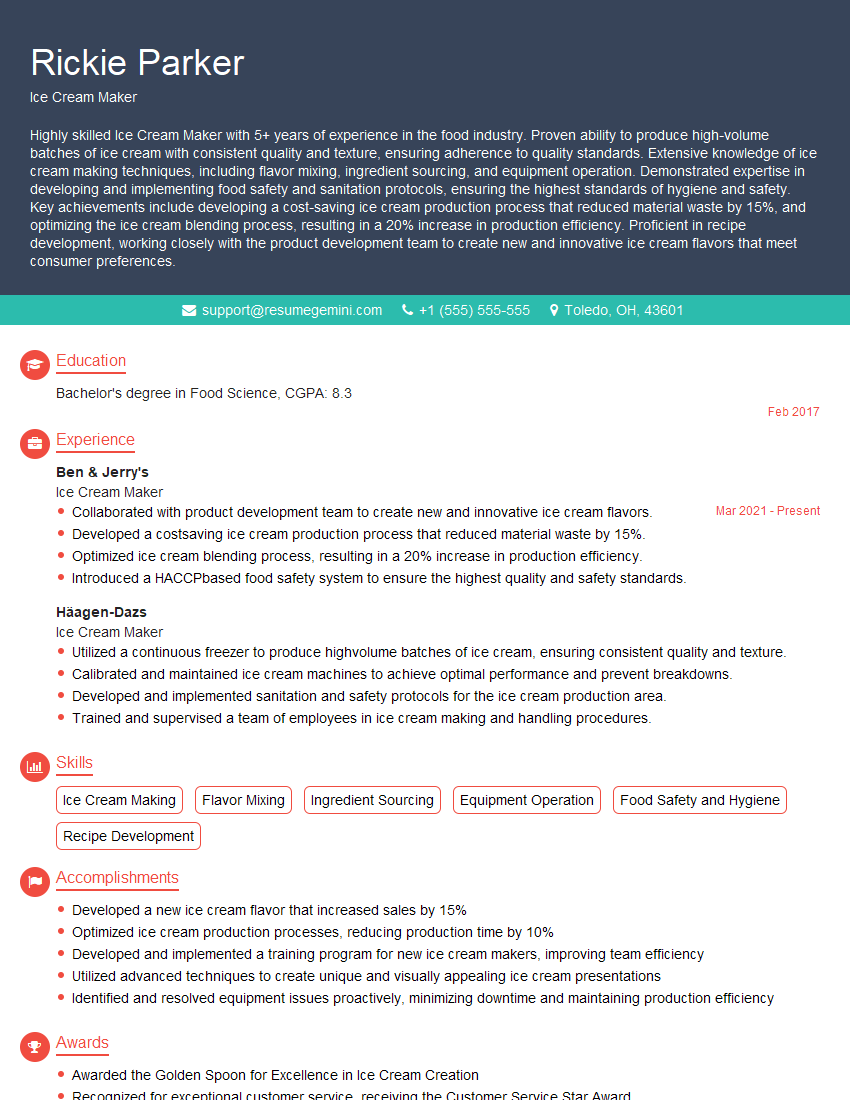

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ice Cream Maker

1. What are the different types of ice cream machines and their uses?

Ice cream machines can be classified into several types, each designed for specific purposes:

- Batch freezers: These machines are used to produce small batches of ice cream, typically in a home or small-scale setting. They consist of a container where the ingredients are mixed and frozen while rotating.

- Continuous freezers: These machines are designed for large-scale production of ice cream. They continuously feed a mixture of ingredients into a freezing cylinder, where it is frozen and extruded as finished ice cream.

- Soft-serve machines: These machines are used to produce soft-serve ice cream, which has a higher air content and a lower freezing point than traditional ice cream. They dispense ice cream directly from the machine.

- Specialty machines: These machines are used to make specialized types of ice cream, such as gelato, sorbet, and frozen yogurt. They may have different freezing mechanisms or features to achieve specific textures or flavors.

2. Describe the process of making ice cream using a commercial ice cream machine

Preparing the mix

- Weigh and mix the ingredients according to the recipe (e.g., milk, cream, sugar, flavors, stabilizers).

- Pasteurize the mix to kill bacteria and ensure food safety.

- Homogenize the mix to blend the ingredients and prevent ice crystal formation.

Freezing the mix

- Churn the mix in an ice cream machine. The machine’s freezing cylinder and agitator cool and beat the mix, incorporating air and creating a smooth, frozen texture.

- Control the freezing time and temperature to achieve the desired consistency.

Hardening the ice cream

- Transfer the churned ice cream into containers.

- Store the ice cream in a freezer at a temperature below 0°F (-18°C) to further harden it and improve its stability.

3. How do you maintain and clean ice cream machines?

- Daily cleaning: Rinse the machine thoroughly with hot water after use to remove any residual mix. Dismantle and clean removable parts, such as the freezing cylinder, agitator, and gaskets.

- Periodic maintenance: Perform regular maintenance checks to ensure the machine is functioning properly. This includes checking the motor, drive belts, and electrical connections.

- Deep cleaning: At least once a month, deep clean the machine using a specialized cleaning solution and following the manufacturer’s instructions.

- Sanitization: Sanitize the machine thoroughly to eliminate any bacteria or microorganisms. Use a food-grade sanitizer and follow the manufacturer’s instructions.

4. What factors affect the texture and quality of ice cream?

- Mix composition: The balance of ingredients, such as milk, cream, sugar, and stabilizers, affects the texture, sweetness, and smoothness of the ice cream.

- Freezing rate: The rate at which the mix is frozen influences the size and distribution of ice crystals. A slow freezing rate results in larger ice crystals and a coarser texture.

- Air content: The amount of air incorporated into the mix during churning determines the lightness and fluffiness of the ice cream.

- Temperature: The storage temperature of the ice cream affects its hardness and texture. Ice cream stored at too low a temperature can become overly hard and icy.

5. How can you troubleshoot common problems with ice cream machines?

- Machine not freezing: Check the motor, drive belts, and electrical connections. Ensure the mix is cold enough before churning.

- Ice cream too hard: Check the storage temperature. The ice cream may have been frozen for too long or at too low a temperature.

- Ice cream too soft: Check the freezing rate and mix composition. The freezing rate may be too slow or the mix may lack stabilizers.

- Leaking machine: Inspect the gaskets and seals for damage or wear. Tighten if necessary.

6. What are the different types of ingredients used in ice cream making?

- Dairy: Milk, cream, and buttermilk provide the base and richness of the ice cream.

- Sweeteners: Sugar, corn syrup, and honey provide sweetness and help stabilize the mix.

- Stabilizers: Gelatin, guar gum, and locust bean gum prevent ice crystal formation and improve texture.

- Emulsifiers: Lecithin and mono- and diglycerides help combine water and oil-based ingredients.

- Flavors: Vanilla, chocolate, fruit extracts, and spices add flavor to the ice cream.

7. What is the importance of pasteurization in ice cream making?

- Safety: Pasteurization destroys harmful bacteria and microorganisms, ensuring the safety of the ice cream for consumption.

- Shelf life: Pasteurization extends the shelf life of ice cream by eliminating spoilage organisms.

- Flavor: Pasteurization helps improve the flavor of ice cream by removing undesirable microorganisms that can produce off-flavors.

8. How can you create unique and innovative ice cream flavors?

- Experiment with different ingredients: Explore various flavors, spices, fruits, and other ingredients to create new combinations.

- Use seasonal ingredients: Incorporate fresh, seasonal ingredients to highlight their unique flavors and create limited-time offerings.

- Collaborate with other businesses: Partner with local coffee roasters, chocolatiers, or breweries to create crossover flavors that combine the best of different worlds.

- Stay updated on trends: Monitor industry trends and customer preferences to identify emerging flavors and concepts.

9. How do you handle customer complaints or feedback regarding ice cream quality?

- Listen attentively: Allow the customer to fully express their concerns and avoid interrupting.

- Apologize and empathize: Acknowledge the customer’s dissatisfaction and show understanding for their experience.

- Investigate the complaint: Check the batch or production records to determine if there were any issues or deviations.

- Resolve the issue: Offer a replacement, refund, or other compensation to address the customer’s concerns.

- Follow up: Contact the customer again to ensure their satisfaction and gather any additional feedback.

10. What are your strengths and weaknesses as an ice cream maker?

Strengths:

- Expertise in ice cream production techniques

- Knowledge of different ice cream machines and their operation

- Experience in creating and developing new ice cream flavors

- Attention to detail and commitment to quality

- Strong work ethic and ability to work in a fast-paced environment

Weaknesses:

- Limited experience in managing a large-scale ice cream production facility

- Still developing my knowledge of ice cream science and flavor chemistry

- Can sometimes be too focused on perfecting flavors and may need to improve my efficiency at times

- I am eager to learn and grow in my role

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ice Cream Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ice Cream Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Ice Cream Maker is responsible for the production of ice cream and other frozen desserts. They are tasked with ensuring the quality and consistency of the products, as well as adhering to food safety and sanitation standards.

1. Production and Operation

An Ice Cream Maker is involved in all aspects of ice cream production, from mixing and freezing ingredients to packaging and storage. They must be able to operate and maintain the complex machinery used in the production process.

- Mix and freeze ingredients according to specified recipes.

- Monitor and adjust equipment to ensure proper operation.

- Troubleshoot and resolve any issues that arise during production.

- Maintain a clean and sanitary work environment.

2. Quality Control

The quality of the ice cream produced is paramount. Ice Cream Makers are responsible for ensuring that all products meet the company’s standards.

- Inspect raw materials and finished products for quality.

- Conduct taste tests and sensory evaluations.

- Develop and implement quality control procedures.

- Maintain accurate records of all quality control activities.

3. Sanitation

The production of ice cream requires strict adherence to food safety and sanitation standards. Ice Cream Makers must be trained in and follow all applicable regulations.

- Clean and sanitize all equipment and work surfaces.

- Follow proper hand washing and hygiene procedures.

- Monitor temperatures and other critical control points.

- Maintain a pest-free environment.

4. Customer Service

Ice Cream Makers may interact with customers on occasion, particularly in small-scale or artisanal settings. They should be able to provide excellent customer service and answer any questions about the products.

- Provide product information to customers.

- Address any customer concerns or complaints.

- Promote and sell ice cream products.

- Build and maintain positive relationships with customers.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some tips to help you ace your interview for an Ice Cream Maker position:

1. Research the Company

Before the interview, take some time to research the company you are applying to. This will help you understand their values, mission, and the specific role of the Ice Cream Maker within the organization.

- Visit the company’s website and social media pages.

- Read articles and news about the company.

- Talk to your network to see if anyone has any insights.

2. Practice Your Answers

Once you have a good understanding of the company, you can start to practice your answers to common interview questions. Think about your experiences and skills, and how they align with the job requirements. Prepare specific examples that demonstrate your abilities.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Be concise and clear in your delivery.

- Practice out loud so that you can become more comfortable with your answers.

3. Be Enthusiastic and Passionate

Ice Cream Makers are passionate about their work. They love creating delicious frozen treats and bringing joy to others. If you are passionate about ice cream, make sure to convey that during the interview.

- Share your favorite ice cream flavors and why you like them.

- Talk about your experiences making ice cream at home or in previous jobs.

- Explain how you would contribute to the company’s mission of creating delicious ice cream.

4. Be Prepared to Ask Questions

At the end of the interview, the interviewer will likely ask if you have any questions. This is your opportunity to learn more about the company and the position. Prepare a few thoughtful questions that show your interest and engagement.

- Ask about the company’s plans for new product development.

- Inquire about the training and support provided to new employees.

- Ask about the company’s commitment to sustainability and social responsibility.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Ice Cream Maker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.