Are you gearing up for a career in Icicle Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Icicle Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

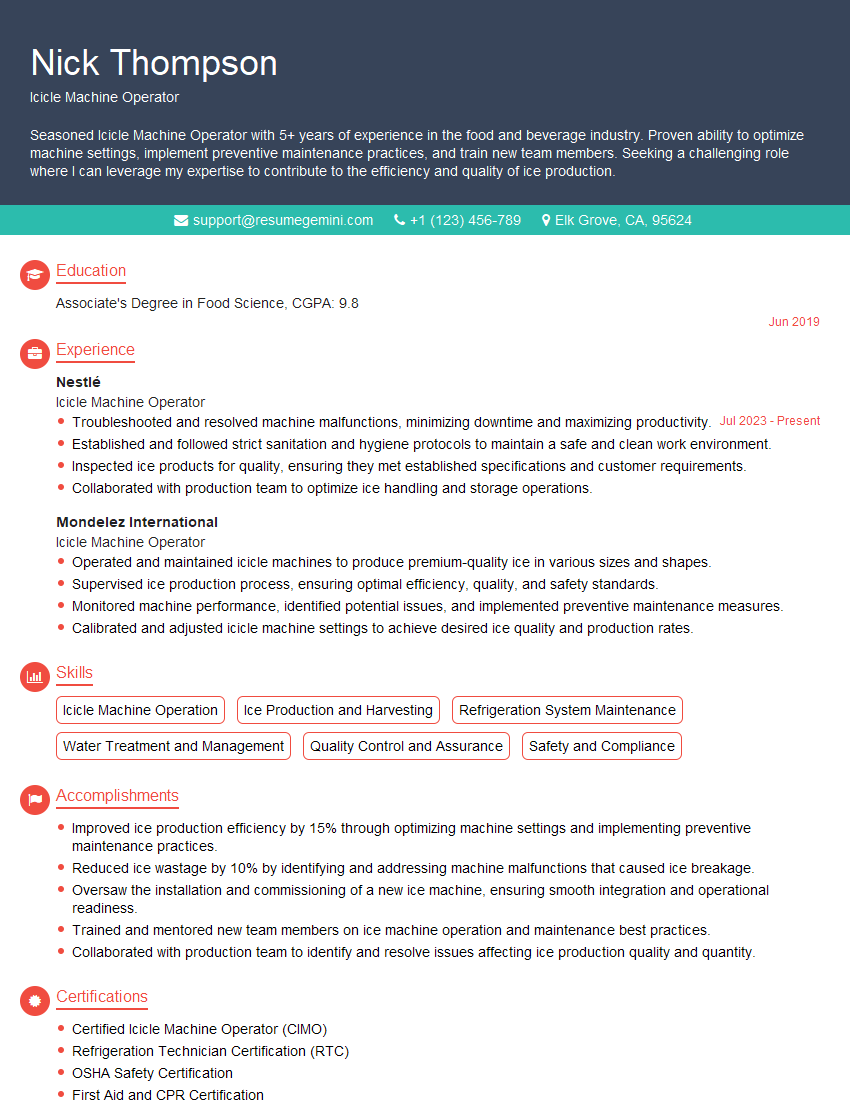

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Icicle Machine Operator

1. Describe the process of operating an icicle machine?

The process of operating an icicle machine involves several key steps:

- Preparing the ice molds: First, the ice molds are thoroughly cleaned and sanitized to ensure the production of clean and hygienic ice.

- Filling the molds with water: The molds are then filled with fresh, clean water to the appropriate level indicated on the machine.

- Freezing the ice: The machine’s refrigeration system is activated, and the water in the molds begins to freeze. The freezing time varies depending on the size and shape of the ice being produced.

- Thawing and harvesting the ice: Once the ice is fully frozen, the machine enters a thawing cycle. The molds are heated slightly, causing the ice to release from the molds. The ice is then harvested and collected in a bin or conveyor.

2. What are the different types of icicle machines and their applications?

Common Types of Icicle Machines

- Self-contained machines: These machines are standalone units that include all the necessary components, such as the compressor, condenser, and evaporator, within a single housing.

- Remote machines: These machines have the refrigeration system located separately from the ice-making unit. This allows for greater flexibility in installation and maintenance.

Applications of Icicle Machines

- Commercial kitchens: Ice is essential for chilling drinks, preserving food, and creating ice sculptures.

- Hospitals and medical facilities: Ice is used for medical purposes, such as cooling injuries and preserving blood products.

- Industrial applications: Ice is used in various industrial processes, such as cooling machinery and preserving perishable goods.

3. What are the key maintenance procedures for an icicle machine?

To ensure optimal performance and longevity, regular maintenance of an icicle machine is crucial. Key maintenance procedures include:

- Cleaning: Regularly cleaning the machine’s components, including the ice molds, water filters, and condenser coils, is essential to prevent buildup and ensure hygienic ice production.

- Lubrication: Lubricating moving parts, such as bearings and gears, helps reduce friction and wear, extending the machine’s lifespan.

- Inspecting and replacing components: Regularly inspecting and replacing worn or damaged components, such as water filters and gaskets, is essential for maintaining the machine’s efficiency and preventing breakdowns.

- Refrigerant monitoring: Monitoring the refrigerant levels and ensuring proper circulation are crucial for efficient ice production.

4. How would you troubleshoot common problems with an icicle machine?

Troubleshooting common problems with an icicle machine requires a systematic approach:

- Identify the problem: Clearly identify the specific issue or symptom the machine is exhibiting.

- Check for obvious causes: Inspect for loose connections, power outages, or any visible damage that could be causing the problem.

- Refer to the manufacturer’s manual: Consult the machine’s manual for specific troubleshooting guidance and recommended solutions.

- Perform diagnostic tests: Conduct diagnostic tests, such as checking water flow, refrigerant pressure, and electrical continuity, to pinpoint the root cause of the issue.

5. What are the safety precautions to observe when operating an icicle machine?

Observing proper safety precautions is essential when operating an icicle machine:

- Electrical safety: Ensure the machine is properly grounded and all electrical connections are secure.

- Water safety: Verify that the water supply is clean and free of contaminants.

- Personal protective equipment: Wear appropriate personal protective equipment, such as gloves and eye protection, when handling ice or performing maintenance.

- Avoid contact with moving parts: Keep hands and body parts away from moving components, such as the ice harvesting mechanism.

- Follow manufacturer’s instructions: Always follow the manufacturer’s operating and safety guidelines for the specific icicle machine being used.

6. Explain the role of the compressor in an icicle machine?

The compressor plays a crucial role in an icicle machine’s refrigeration system:

- Compressing the refrigerant: The compressor compresses the refrigerant gas, increasing its pressure and temperature.

- Heat transfer: The compressed refrigerant is then pumped to the condenser, where it releases heat to the surrounding environment.

- Expansion and evaporation: The refrigerant then passes through an expansion valve, which reduces its pressure and temperature. This causes the refrigerant to evaporate and absorb heat from the water in the ice molds.

7. What factors affect the production capacity of an icicle machine?

Several factors influence the production capacity of an icicle machine:

- Machine size and design: Larger machines with more ice molds can produce more ice.

- Refrigeration system efficiency: An efficient refrigeration system will produce ice faster.

- Water temperature: Colder water freezes faster, increasing production capacity.

- Ambient temperature: Higher ambient temperatures can reduce production capacity.

- Ice mold shape and size: Different mold shapes and sizes can affect the freezing time.

8. How do you ensure the quality and hygiene of the ice produced by an icicle machine?

Ensuring the quality and hygiene of ice is crucial:

- Regular cleaning and sanitization: Thoroughly clean and sanitize the ice molds, water filters, and other components regularly to prevent contamination.

- Water quality: Use clean, filtered water to make ice to avoid impurities and bacteria.

- Proper storage: Store ice in clean, insulated containers to prevent contamination and maintain its quality.

- Follow manufacturer’s guidelines: Adhere to the manufacturer’s guidelines for proper operation and maintenance of the icicle machine.

9. What are the environmental considerations related to operating an icicle machine?

Operating an icicle machine involves environmental considerations:

- Refrigerant selection: Choose environmentally friendly refrigerants with low global warming potential (GWP).

- Energy efficiency: Select energy-efficient icicle machines to reduce energy consumption.

- Water conservation: Implement water-saving practices, such as using water-cooled condensers and recycling water during cleaning.

- Proper disposal: Dispose of ice machine waste, such as filters and refrigerants, responsibly.

10. What are the emerging trends and advancements in icicle machine technology?

The icicle machine industry is constantly evolving:

- Automated systems: Advanced icicle machines feature automated controls for ice production and maintenance.

- Smart technology: Icicle machines are becoming increasingly connected, allowing for remote monitoring and control.

- Sustainable designs: Manufacturers are focusing on developing energy-efficient and environmentally friendly icicle machines.

- Improved hygiene: New technologies are being introduced to enhance the hygiene and safety of ice production.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Icicle Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Icicle Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Icicle Machine Operators are responsible for overseeing the operations of icicle machines, which are used to create icicles for decorative purposes or for use in commercial settings such as ice rinks and hockey arenas.

1. Monitoring and Controlling Machine Operations

Operate and monitor icicle machines to ensure proper functioning.

- Adjust machine settings to maintain desired temperature and water flow.

- Monitor water levels and replenish as needed.

2. Maintaining Equipment

Maintain and clean icicle machines and related equipment to ensure optimal performance.

- Lubricate and clean machine components.

- Inspect equipment regularly for signs of wear or damage.

3. Harvesting and Packaging Icicles

Harvest and package icicles efficiently and safely.

- Remove icicles from the machine and pack them for storage or shipment.

- Ensure that icicles are handled carefully to prevent breakage.

4. Safety and Environmental Compliance

Adhere to safety protocols and maintain a clean and organized work environment.

- Follow established safety procedures and use appropriate personal protective equipment.

- Dispose of waste materials properly according to environmental regulations.

Interview Tips

To ace the interview for an Icicle Machine Operator position, it is crucial to prepare thoroughly and demonstrate your understanding of the job responsibilities and the industry. Here are some tips to help you stand out:

1. Research the Company and Position

Familiarize yourself with the company’s background, mission, products or services, and culture.

- Visit the company’s website and social media pages to gather information.

- Review industry publications and news to stay informed about recent trends.

2. Highlight Relevant Skills and Experience

Emphasize your technical abilities, such as machine operation, maintenance, and troubleshooting.

- Quantify your accomplishments whenever possible, using specific metrics and results.

- If you have experience in a related field, such as food processing or manufacturing, highlight the transferable skills you have developed.

3. Prepare for Common Interview Questions

Practice answering common interview questions, such as:

- “Describe your experience operating and maintaining icicle machines.”

- “How do you ensure the safety and quality of the icicles you produce?”

- “What is your understanding of environmental regulations and how do you comply with them?”

4. Ask Thoughtful Questions

Asking thoughtful questions during the interview demonstrates your interest and engagement.

- Inquire about the company’s growth plans or sustainability initiatives.

- Ask about opportunities for professional development or advancement.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Icicle Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!