Are you gearing up for an interview for a Icing Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Icing Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

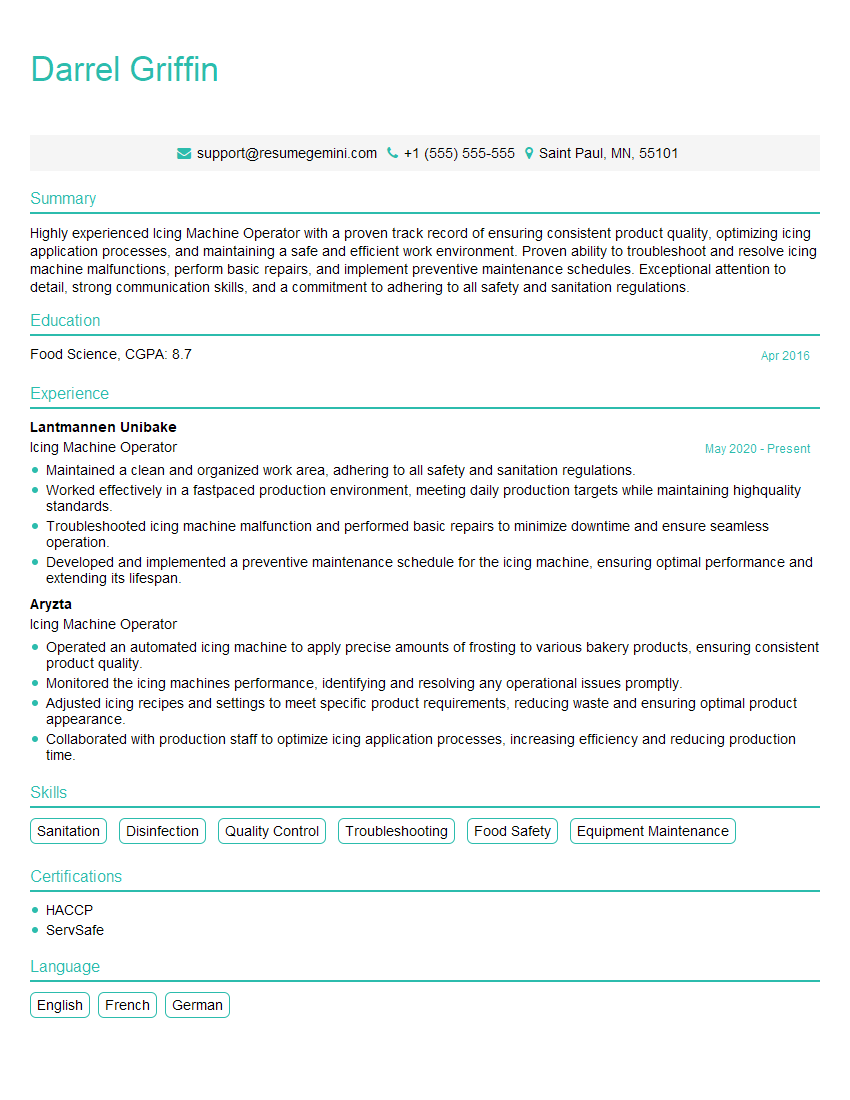

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Icing Machine Operator

1. Explain the process of operating an icing machine?

The process of operating an icing machine involves several key steps to ensure efficient and safe production of icing:

- Sanitation and Preparation: Before starting the machine, it is essential to thoroughly clean and sanitize the machine, including all contact surfaces, to prevent contamination.

- Ingredient Preparation: The correct ingredients (e.g., sugar, water, stabilizers) are measured and mixed according to the recipe to achieve the desired consistency and texture.

- Machine Setup: The icing machine is set up based on the desired icing type (e.g., buttercream, royal icing, fondant) by adjusting settings such as temperature, speed, and nozzle size.

- Icing Production: The prepared ingredients are loaded into the machine, and the icing is produced by mixing and aerating the ingredients to create the desired texture and volume.

- Monitoring and Adjustment: During the icing production, the operator monitors the machine’s performance, such as temperature, consistency, and flow rate, and makes adjustments as needed to ensure the icing meets quality standards.

- Cleaning and Maintenance: After use, the icing machine is thoroughly cleaned and sanitized to prevent bacterial growth and ensure the machine’s longevity.

2. Describe the different types of icing machines and their applications?

Rotary Icing Machines:

- Used for high-volume production of icing for cakes, pastries, and other desserts.

- Capable of producing a variety of icing consistencies, from soft and fluffy to stiff and firm.

Vertical Icing Machines:

- Designed for smaller-scale icing production, suitable for bakeries and confectioneries.

- Offer greater precision and control over icing consistency and aeration.

Batch Icing Machines:

- Used for producing small batches of icing, ideal for artisanal bakeries and home cooks.

- Allow for customization and experimentation with different flavors and textures.

3. What are the critical maintenance procedures for icing machines?

- Regular Cleaning: Daily cleaning of the machine, including all contact surfaces, piping, and nozzles, to prevent icing buildup and contamination.

- Lubrication: Lubricating moving parts as per the manufacturer’s instructions to ensure smooth operation and reduce wear and tear.

- Temperature Control: Maintaining the proper operating temperature to ensure the icing’s quality and consistency.

- Calibration: Regularly calibrating the machine’s settings (e.g., speed, nozzle size) to ensure accurate and consistent icing production.

- Electrical Maintenance: Checking electrical connections and components for any damage or loose connections to prevent electrical hazards.

4. Explain the importance of temperature control in icing production?

Temperature control is crucial in icing production as it significantly affects the icing’s consistency, texture, and quality:

- Proper Viscosity: Maintaining the correct temperature allows the icing to achieve the desired viscosity for easy application and smooth spreading.

- Crystallization Control: Controlling the temperature prevents sugar crystallization, which can result in a grainy or gritty texture.

- Setting Time: Temperature influences the setting time of the icing, allowing for precise control over when the icing firms up or sets.

- Aeration: Optimal temperature facilitates proper aeration, creating a light and fluffy icing with the desired volume.

- Shelf Life: Maintaining the correct temperature during storage helps extend the shelf life of the icing and prevents spoilage.

5. Describe the different types of nozzles used in icing machines and their applications?

- Round Nozzles: Available in various sizes, used for creating dots, lines, borders, and writing.

- Star Nozzles: Produce star-shaped designs, ideal for decorative borders, swirls, and rosettes.

- Leaf Nozzles: Create leaf-like designs, suitable for adding intricate details and embellishments.

- Basketweave Nozzles: Produce a basketweave pattern, often used for cakes and cupcakes.

- Petal Nozzles: Create realistic flower petals, perfect for floral decorations.

6. Explain the troubleshooting process for common icing machine problems?

- No Icing Flow: Check for clogs in the piping system, ensure sufficient icing supply, and verify that the machine is properly assembled.

- Inconsistent Icing Consistency: Adjust the temperature, speed, or nozzle size as needed to achieve the desired consistency.

- Leaking Machine: Inspect for loose connections, worn seals, or cracks in the piping system and tighten or replace as necessary.

- Overheating: Check for proper ventilation, clean the machine to remove icing buildup, and ensure that the motor is not overloaded.

- Electrical Faults: Disconnect the machine, check for any loose connections or damaged wires, and contact a qualified electrician if necessary.

7. Describe the safety precautions that should be followed when operating an icing machine?

- Proper Attire: Wear appropriate clothing, including a hairnet and gloves, to maintain hygiene and prevent contamination.

- Machine Stability: Ensure the machine is placed on a stable and level surface to prevent accidents.

- Electrical Safety: Check electrical cords and connections regularly, and keep the machine away from water or moisture.

- Moving Parts: Be cautious of moving parts, such as rotating blades or belts, and keep hands clear.

- Hot Surfaces: Avoid touching hot surfaces on the machine, such as the heating element.

8. What are the essential qualities of a successful Icing Machine Operator?

- Attention to Detail: Ensuring precision in icing production and consistency.

- Problem-Solving Skills: Ability to identify and resolve common icing machine issues.

- Hygiene Consciousness: Maintaining a clean and sanitary work environment.

- Physical Stamina: Standing for extended periods and operating machinery.

- Teamwork and Communication: Collaborating with colleagues in a production setting.

9. Explain how you would optimize the efficiency of an icing production line?

- Process Optimization: Streamlining the production process to reduce bottlenecks and improve flow.

- Regular Maintenance: Scheduling regular maintenance to prevent breakdowns and ensure smooth operation.

- Staff Training: Providing proper training to operators to ensure efficient and safe machine usage.

- Production Planning: Forecasting demand and planning production schedules to avoid overproduction or shortages.

- Waste Reduction: Implementing measures to minimize icing waste and optimize ingredient usage.

10. Describe how you would handle a situation where the icing machine malfunctions during a production run?

- Safety First: Immediately shut down the machine and disconnect the power supply.

- Troubleshooting: Attempt to identify the cause of the malfunction based on common issues and troubleshooting procedures.

- Repair or Replacement: If the issue cannot be resolved, notify the supervisor and arrange for repairs or replacement parts.

- Communication: Inform affected team members about the situation and estimated repair time to minimize disruption.

- Documentation: Document the incident, including the time, nature of the malfunction, and any actions taken.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Icing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Icing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Icing Machine Operator is responsible for producing uniform and high-quality icing applications onto various products to ensure consistent production.

1. Maintain and Sanitize the Machine

Confirms proper functioning of the icing machine, including routine maintenance, inspections and cleaning.

- Perform daily start-up and end-of-shift procedures.

- Inspect belts, chains, and other equipment for potential malfunctions.

2. Adjust and Calibrate Machine Settings

Accurately modifies machine settings to produce consistent quantity, temperature, and texture of icing.

- Use measuring instruments to ensure precise and consistent output.

- Monitor ongoing operations to ensure optimal machine performance.

3. Troubleshoot and Repair Equipment

Understands basic equipment operation to resolve issues and maintain uptime.

- Identify and diagnose machine malfunctions quickly and efficiently.

- Perform minor repairs and adjustments to ensure uninterrupted production.

4. Maintain a Safe and Clean Work Environment

Prioritizes safety and hygiene in daily operations to maintain a clean and compliant workplace.

- Wear appropriate protective gear and ensure colleagues do the same.

- Follow established safety protocols and report potential hazards promptly.

Interview Tips

Preparing effectively for an Icing Machine Operator interview can significantly increase your chances of success. Here are some tips and tricks to help you ace the interview:

1. Research the Company and the Role

Understanding the company’s industry, values, and specific requirements for the role will enable you to tailor your responses accordingly.

- Visit the company website to gather information about their history, products, and services.

- Review the job description thoroughly to identify the key responsibilities and qualifications.

2. Practice Common Interview Questions

Anticipating and preparing for potential interview questions can boost your confidence and articulation during the actual interview.

- Prepare answers to basic interview questions, such as “Tell me about yourself” and “Why are you interested in this role?”

- Use the STAR method (Situation, Task, Action, Result) to craft concise and impactful answers that highlight your skills and experience.

3. Showcase Your Understanding of Icing Machine Operations

Demonstrating your knowledge of the industry and technical aspects of icing machine operations will impress the interviewer.

- Discuss your experience with different types of icing machines, their functionalities, and maintenance procedures.

- Explain your understanding of the role of icing in food production and the quality standards required.

4. Emphasize Your Safety Consciousness

Highlighting your commitment to safety will demonstrate your professionalism and responsibility.

- Share examples of safety protocols you have followed in previous roles.

- Explain how you prioritize maintaining a clean and sanitary work environment.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Icing Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.