Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Implement Mechanic position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

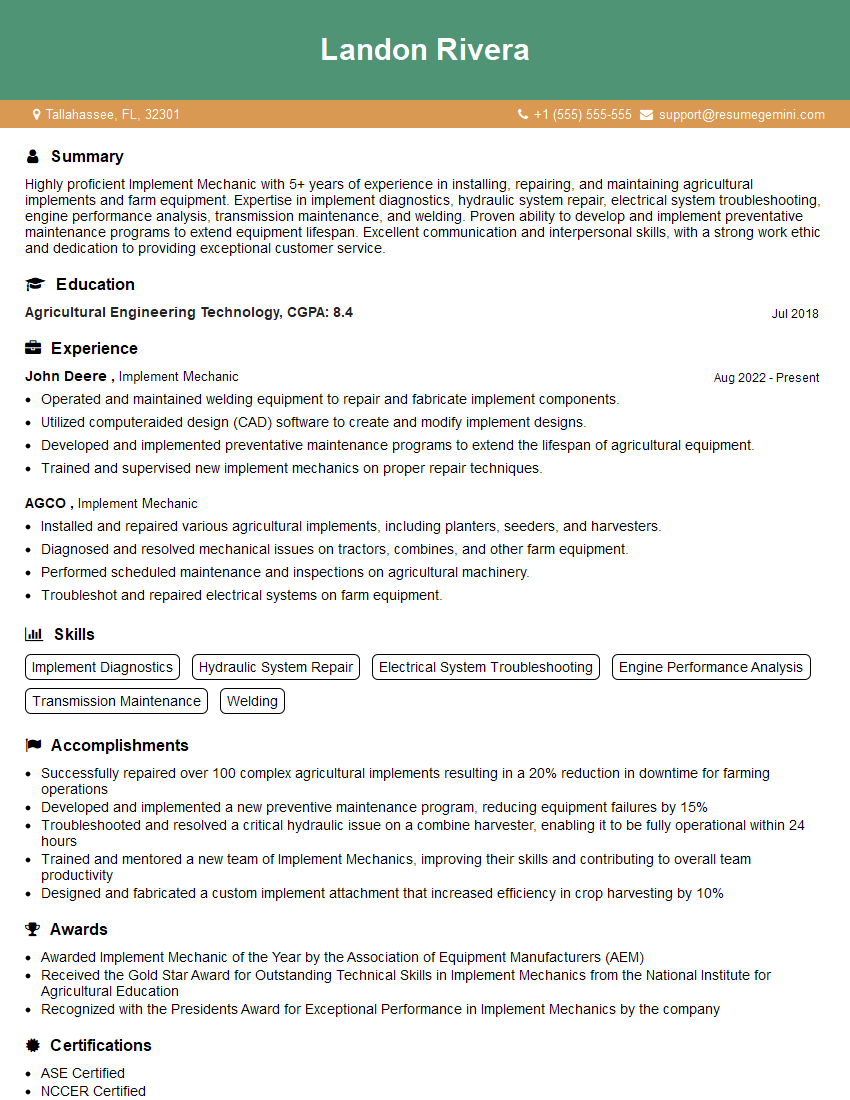

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Implement Mechanic

1. What are the common types of agricultural implements?

The common types of agricultural implements are:

- Tillage implements:

- Plows

- Harrows

- Discs

- Planters

- Harvesting implements:

- Combines

- Grain drills

- Forage harvesters

- Baling machines

- Hay and forage implements:

- Mowers

- Tedders

- Rakes

- Balers

- Livestock implements:

- Fencing

- Waterers

- Feeders

- Handling equipment

2. What are the different types of tractors used in agriculture?

The different types of tractors used in agriculture include:

Four-wheel drive tractors

- Used for a variety of farming operations, including tillage, planting, harvesting, and transporting.

- Provide good traction and stability in all types of terrain.

Two-wheel drive tractors

- Lighter and more maneuverable than four-wheel drive tractors.

- Used for tasks such as mowing, spraying, and cultivating.

Track tractors

- Provide the best traction and stability in wet or muddy conditions.

- Used for heavy-duty tasks such as land leveling and clearing.

3. Describe the different types of hydraulic systems used in agricultural implements.

- Open-center hydraulic systems:

- The pump continuously flows fluid, which is then directed to the implement.

- Less efficient than closed-center systems, but simpler and less expensive.

- Closed-center hydraulic systems:

- The pump only flows fluid when the implement is in use.

- More efficient than open-center systems, but more complex and expensive.

- Load-sensing hydraulic systems:

- The pump automatically adjusts its output to match the load on the implement.

- The most efficient type of hydraulic system, but also the most expensive.

4. What are the different types of PTO (power take-off) shafts used in agricultural implements?

- Category 1 PTO shafts:

- Used for implements that require less than 50 horsepower.

- Category 2 PTO shafts:

- Used for implements that require between 50 and 100 horsepower.

- Category 3 PTO shafts:

- Used for implements that require more than 100 horsepower.

5. How do you troubleshoot a hydraulic system on an agricultural implement?

- Check the hydraulic fluid level and condition.

- Check for leaks in the hydraulic system.

- Check the hydraulic pump for proper operation.

- Check the hydraulic valves for proper operation.

- Check the hydraulic cylinders for proper operation.

6. How do you troubleshoot an electrical system on an agricultural implement?

- Check the battery for proper voltage.

- Check the alternator for proper output.

- Check the wiring for damage or loose connections.

- Check the fuses and circuit breakers for proper operation.

- Check the electrical components for proper operation.

7. How do you maintain an agricultural implement?

- Keep the implement clean and free of debris.

- Lubricate all moving parts regularly.

- Check the hydraulic fluid level and condition regularly.

- Check the electrical system for damage or loose connections regularly.

- Store the implement in a dry, protected place when not in use.

8. What are the safety precautions that should be taken when working on agricultural implements?

- Wear appropriate safety gear, including gloves, safety glasses, and earplugs.

- Read and understand the operator’s manual for the implement.

- Never operate an implement that is not in good working condition.

- Be aware of your surroundings and other people in the area.

- Never work on an implement that is running.

9. What are the common problems that can occur with agricultural implements?

- Hydraulic leaks

- Electrical problems

- Mechanical breakdowns

- Wear and tear

- Corrosion

10. What are the latest trends in agricultural implement technology?

- Precision agriculture technologies

- Autonomous agricultural implements

- Electric agricultural implements

- Data-driven farming

- Sustainable agricultural practices

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Implement Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Implement Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of an Implement Mechanic

1. Equipment Maintenance and Repairs

Implement Mechanics diagnose, troubleshoot, and repair a wide range of agricultural equipment, including tractors, combines, planters, and harvesters. They locate and replace worn or damaged parts, ensure proper functioning, and perform routine maintenance to minimize breakdowns and extend equipment lifespan.

2. Installation and Modifications

When new equipment or technology is introduced, Implement Mechanics handle the installation and modification process. They assemble, adjust, and integrate new components into existing systems, ensuring they operate seamlessly with the rest of the equipment.

3. Electrical and Hydraulic System Maintenance

Agricultural machinery relies heavily on electrical and hydraulic systems for efficient operation. Implement Mechanics maintain, diagnose, and repair these complex systems, troubleshoot electrical faults, and ensure proper fluid levels and pressure.

4. Safety Protocols and Compliance

Working with heavy machinery requires strict adherence to safety protocols. Implement Mechanics ensure that equipment meets safety regulations, conduct regular inspections, and provide training and guidance to other operators on safe operating practices.

5. Customer Support and Technical Assistance

Implement Mechanics collaborate closely with farmers and other equipment users. They provide technical assistance, troubleshoot issues remotely or onsite, and ensure customer satisfaction by resolving equipment problems promptly.

Interview Preparation Tips for Implement Mechanics

To ace an interview for an Implement Mechanic position, candidates should prepare thoroughly. Here are some tips to help them succeed:

1. Research the Company and Position

Familiarize yourself with the company’s history, values, and the specific duties and responsibilities of the Implement Mechanic role. This knowledge will help you tailor your answers and demonstrate your understanding of the job.

2. Highlight Relevant Experience and Skills

Emphasize your hands-on experience in agricultural equipment repair and maintenance. Quantify your accomplishments whenever possible, using specific examples of successful troubleshooting or repairs. Highlight your proficiency in electrical and hydraulic systems.

3. Practice Common Interview Questions

Prepare for common interview questions like “Tell me about yourself,” “Why do you want to work here,” and “Describe a challenging repair you handled.” Practice answering these questions clearly and concisely, showcasing your problem-solving abilities.

4. Demonstrate Safety Awareness

Emphasize your commitment to safety protocols. Describe your experience in conducting equipment inspections, following safety guidelines, and promoting a safe working environment.

5. Ask Informed Questions

During the interview, ask thoughtful questions to show your interest in the company and the position. Questions about the company’s growth plans, training opportunities, or the latest industry advancements demonstrate your enthusiasm.

6. Dress Professionally and Arrive Punctually

First impressions matter. Dress professionally and arrive on time for the interview. This shows that you respect the interviewer and the company.

7. Follow Up

After the interview, send a thank-you note to the interviewer. Express your gratitude for their time and reiterate your interest in the position. Following up shows professionalism and enthusiasm.

Next Step:

Now that you’re armed with the knowledge of Implement Mechanic interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Implement Mechanic positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini