Feeling lost in a sea of interview questions? Landed that dream interview for Impregnator and Drier Helper but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Impregnator and Drier Helper interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

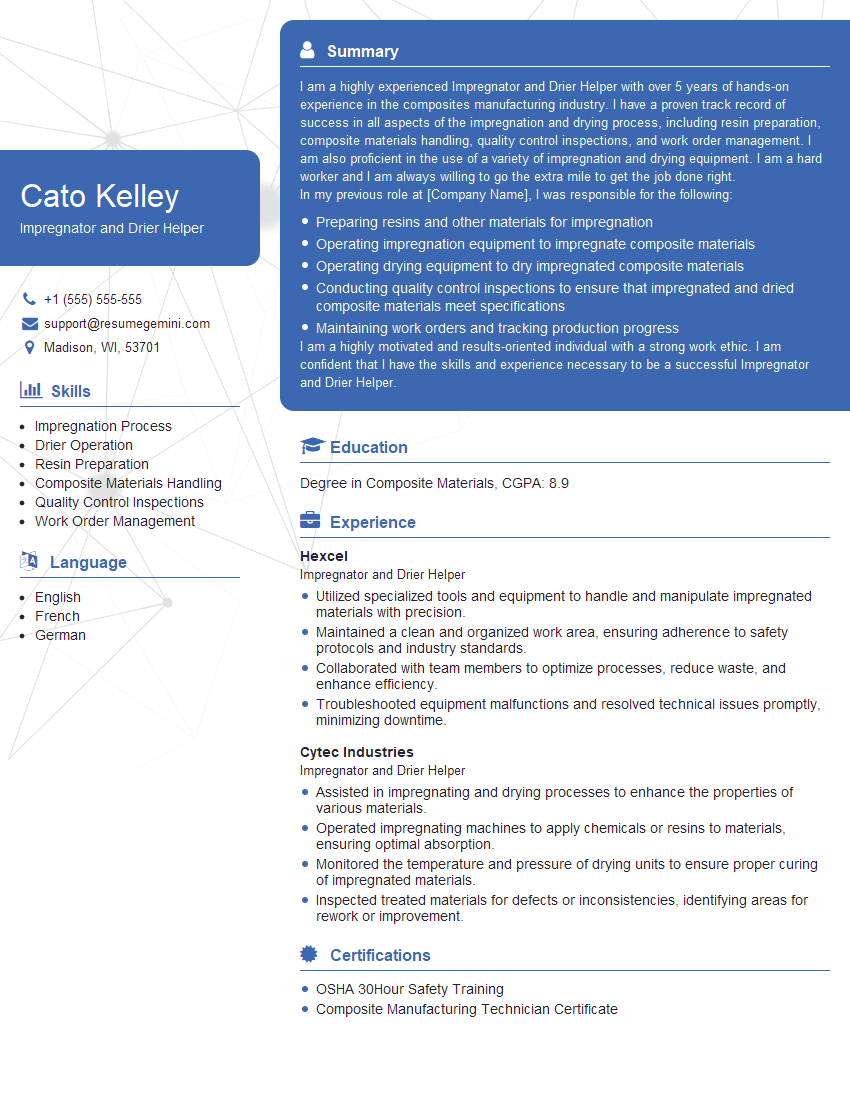

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Impregnator and Drier Helper

1. Explain the process of impregnating a fabric?

Sample Answer

- The impregnation process involves treating a fabric with a chemical solution, typically a resin or polymer, to enhance its properties.

- The fabric is submerged in a bath containing the solution, allowing it to absorb and become saturated with the chemicals.

- After impregnation, the fabric is dried and heat-treated to cure the chemicals, resulting in improved strength, durability, and resistance to elements.

2. What are the different types of drying methods used in textile manufacturing?

Hot air drying

- In this method, hot air is circulated through the fabric to evaporate moisture.

- It is widely used for drying fabrics after impregnation or dyeing processes.

Microwave drying

- Microwave energy is used to heat the fabric and evaporate moisture.

- This method is faster and more energy-efficient than hot air drying but requires specialized equipment.

Vacuum drying

- A vacuum is applied to the drying chamber, lowering the boiling point of water.

- This allows the fabric to dry at lower temperatures, preserving its quality.

3. Describe the importance of monitoring temperature and humidity during the drying process.

Sample Answer

- Temperature and humidity levels significantly impact the drying process.

- Excessive heat can damage the fabric, while insufficient heat can prolong drying times.

- Proper humidity levels prevent the fabric from becoming too dry and brittle or too moist, which can lead to mildew or rot.

- Monitoring these parameters ensures optimal drying conditions, maintaining the fabric’s quality and preventing defects.

4. What are the common defects that can occur during impregnation and drying?

Sample Answer

- Impregnation Defects

- Uneven impregnation, resulting in inconsistent fabric properties.

- Over-impregnation, causing stiffness and reduced fabric flexibility.

- Drying Defects

- Over-drying, leading to fabric brittleness and reduced strength.

- Under-drying, resulting in insufficient moisture removal, which can promote mold growth.

- Wrinkling, caused by uneven drying or improper tensioning during the process.

5. How do you ensure the quality of impregnated and dried fabrics?

Sample Answer

- Quality Control Measures

- Regular testing of fabric properties, such as strength, weight, and moisture content.

- Visual inspection for defects, such as wrinkles, uneven impregnation, or discoloration.

- Monitoring of process parameters, including temperature, humidity, and chemical concentrations.

- Quality Assurance

- Establishing and maintaining standard operating procedures.

- Training operators on proper equipment operation and quality control techniques.

- Continuous improvement initiatives to optimize the process and minimize defects.

6. What safety precautions should be taken during impregnation and drying operations?

Sample Answer

- Chemical Handling

- Wear appropriate personal protective equipment (PPE), including gloves, goggles, and respirators.

- Handle chemicals according to safety data sheets (SDSs).

- Dispose of chemical waste properly.

- Equipment Operation

- Receive proper training on operating impregnation and drying equipment.

- Follow safety guidelines and lockout/tagout procedures.

- Be aware of potential hazards, such as hot surfaces and moving machinery.

- Environmental Safety

- Control emissions from the drying process to prevent air pollution.

- Treat wastewater from the impregnation process to remove chemicals.

7. Describe the maintenance procedures for impregnation and drying equipment.

Sample Answer

- Regular Maintenance

- Clean and inspect equipment regularly.

- Lubricate moving parts as per manufacturer’s instructions.

- Check for any leaks or damage.

- Periodic Maintenance

- Calibrate temperature and humidity sensors.

- Inspect and replace belts, filters, and other components as needed.

- Conduct thorough overhauls at scheduled intervals.

- Record Keeping

- Document all maintenance activities.

- Keep records of inspections, repairs, and replacements.

8. How do you troubleshoot common problems that may arise during impregnation or drying?

Sample Answer

- Impregnation Problems

- Uneven impregnation: Check chemical concentration, immersion time, and fabric tension.

- Over-impregnation: Reduce chemical concentration or immersion time.

- Drying Problems

- Over-drying: Adjust drying temperature and time or increase humidity.

- Under-drying: Increase drying temperature and time or decrease humidity.

- Wrinkling: Ensure proper tensioning of the fabric during drying.

9. What are the key industry trends and advancements in impregnation and drying technologies?

Sample Answer

- Sustainable Technologies

- Using eco-friendly chemicals and processes to reduce environmental impact.

- Energy-efficient equipment and drying methods.

- Automation and Control

- Automated control systems for impregnation and drying processes.

- Sensors and monitoring systems for real-time data collection and optimization.

- Advanced Materials

- Developments in impregnation resins and drying techniques for improved fabric properties.

- Functionalization of fabrics through impregnation and drying.

10. How do you stay updated with the latest industry knowledge and best practices in impregnation and drying?

Sample Answer

- Attend industry conferences and workshops.

- Read technical journals and research papers.

- Network with professionals in the field.

- Seek opportunities for training and development.

- Stay informed about industry regulations and standards.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Impregnator and Drier Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Impregnator and Drier Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Impregnator and Drier Helpers work as assistants to Impregnators or Driers in the manufacturing industry. They support the impregnation and drying processes by performing various tasks, ensuring the smooth operation of production lines.

1. Material Handling and Preparation

Impregnator and Drier Helpers handle and prepare materials required for the impregnation and drying processes. This includes:

- Loading and unloading materials using equipment such as forklifts and conveyors

- Preparing chemicals, resins, and impregnating solutions

- Mixing and dispensing materials according to specified formulations

2. Impregnation Assistance

They assist Impregnators in the impregnation process, which involves treating materials such as paper, wood, or textiles with chemical solutions to improve their properties:

- Assisting in setting up and operating impregnation equipment

- Monitoring impregnation parameters such as temperature, pressure, and dwell time

- Ensuring proper impregnation of materials and maintaining quality standards

3. Drier Assistance

Impregnator and Drier Helpers aid Driers in the drying process, which removes excess moisture or solvents from impregnated materials:

- Assisting in operating drying equipment such as ovens, kilns, or dryers

- Monitoring drying parameters like temperature, humidity, and airflow

- Examining dried materials to ensure they meet specifications

4. Machine Maintenance and Cleaning

They help maintain and clean impregnation and drying machines to ensure optimal performance:

- Performing basic maintenance tasks like lubrication and cleaning

- Identifying and reporting any machine malfunctions or repairs needed

- Ensuring a clean and organized work environment

Interview Tips

To ace an interview for an Impregnator and Drier Helper position, it’s crucial to prepare thoroughly. Here are some tips and hacks to help you stand out:

1. Research the Company and Role

Before the interview, research the company and the specific role you’re applying for. This will give you an understanding of their business, values, and expectations for the position.

- Visit the company’s website and social media pages

- Read industry-related articles and news

- Learn about the company’s products, services, and market position

2. Practice Answering Common Interview Questions

Prepare for typical interview questions and craft well-thought-out answers that highlight your skills and experience.

- “Tell me about your experience in the impregnation or drying industry.”

- “Describe a time when you faced a challenge in material handling or machine maintenance.”

- “Why are you interested in this role at our company?”

3. Showcase Your Technical Skills

As an Impregnator and Drier Helper, technical skills are vital. Emphasize your knowledge of impregnation and drying processes, as well as your experience operating and maintaining related machinery.

- Provide specific examples of your involvement in impregnation or drying operations

- Discuss your understanding of the different parameters involved in these processes

- Highlight any certifications or training you have in relevant areas

4. Highlight Your Teamwork and Problem-Solving Abilities

Teamwork and problem-solving are essential in this role. Share instances where you have effectively worked with others to achieve shared goals and resolved issues on the production line.

- Describe a situation where you identified and resolved a problem with an impregnation or drying machine

- Explain how you handled working under pressure and meeting deadlines

- Provide examples of your ability to collaborate with colleagues

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Impregnator and Drier Helper, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Impregnator and Drier Helper positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.