Are you gearing up for a career in Impregnator Helper? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Impregnator Helper and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

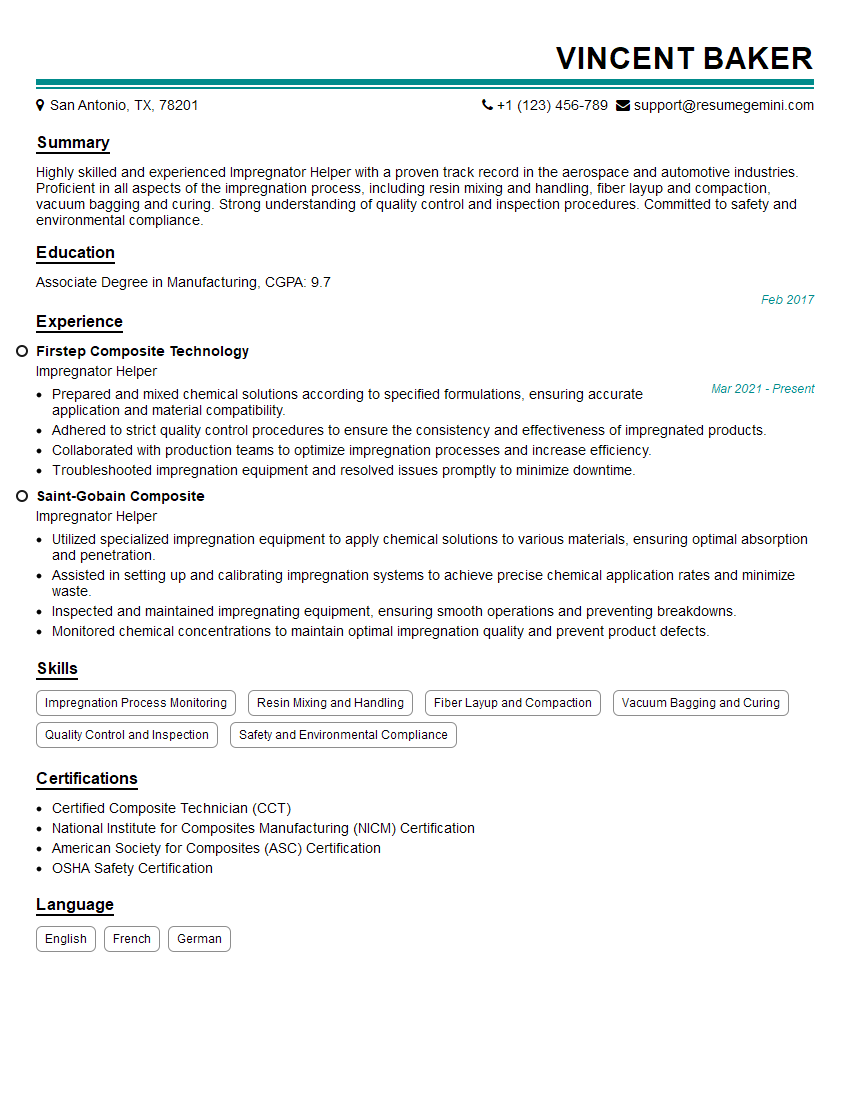

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Impregnator Helper

1. Describe the process of impregnating a material with a resin?

The process of impregnating a material with a resin typically involves the following steps:

- Preparing the material: The material to be impregnated is cleaned and dried to remove any contaminants or moisture that could interfere with the impregnation process.

- Preparing the resin: The resin is mixed with a catalyst or hardener to initiate the curing process.

- Applying the resin: The resin is applied to the material using a brush, roller, or vacuum impregnation method.

- Curing the resin: The material is heated or exposed to ultraviolet light to cure the resin and create a strong bond between the resin and the material.

- Post-treatment: After curing, the impregnated material may undergo additional treatments such as sanding, polishing, or painting to enhance its appearance or properties.

2. What are the different types of resins used in impregnation?

- Epoxy resins: Known for their high strength, durability, and resistance to chemicals and moisture.

- Polyester resins: Cost-effective option with good mechanical properties and resistance to water and solvents.

- Phenolic resins: Offer high thermal stability, electrical insulation, and resistance to acids and alkalis.

- Acrylic resins: Provide excellent clarity, weather resistance, and resistance to yellowing.

- Urethane resins: Flexible and impact-resistant, used in applications requiring vibration dampening or shock absorption.

- Silicones: Known for their high-temperature resistance, flexibility, and water repellency.

3. What are the key factors to consider when selecting a resin for impregnation?

When selecting a resin for impregnation, the following factors should be considered:

- The properties required for the final product, such as strength, durability, chemical resistance, and electrical insulation.

- The viscosity and curing time of the resin, which can affect the impregnation process and production efficiency.

- The compatibility of the resin with the material being impregnated.

- The cost and availability of the resin.

4. What are the common defects that can occur during the impregnation process and how can they be prevented?

- Voids and air bubbles: Caused by insufficient vacuum or degassing during impregnation. Can be prevented by proper vacuum application and degassing techniques.

- Incomplete impregnation: Occurs when the resin does not fully penetrate the material. Can be prevented by optimizing the impregnation parameters such as vacuum level, temperature, and impregnation time.

- Resin bleeding: Excess resin leaking out of the material. Can be prevented by using a resin with the appropriate viscosity and by controlling the impregnation pressure.

- Delamination: Separation between the resin and the material. Can be prevented by ensuring good adhesion between the resin and the material, and by controlling the curing conditions.

5. What are the different methods of applying resin during impregnation?

- Brush application: Manual method using a brush to apply the resin to the material.

- Roller application: Using a roller to spread the resin evenly over the material.

- Vacuum impregnation: Placing the material in a vacuum chamber and applying the resin under vacuum, which draws the resin into the material.

- Pressure impregnation: Applying the resin under pressure, which forces the resin into the material.

6. What are the safety precautions that should be taken when handling resins used in impregnation?

- Wear appropriate personal protective equipment, including gloves, safety glasses, and a respirator.

- Ensure proper ventilation in the work area to avoid exposure to harmful fumes.

- Store resins in a cool, dry, and well-ventilated area, away from ignition sources.

- Follow the manufacturer’s instructions for safe handling and disposal of resins.

7. What is the role of a vacuum in the impregnation process?

Vacuum plays a crucial role in the impregnation process by:

- Removing air and moisture from the material, creating a void for the resin to fill.

- Assisting in the penetration of the resin into the material by reducing the atmospheric pressure.

- Preventing the formation of air bubbles and voids in the impregnated material.

8. What are the benefits of impregnating materials with resin?

- Improved mechanical properties: Resin impregnation can enhance the strength, stiffness, and durability of materials.

- Improved electrical properties: Resin impregnation can provide electrical insulation and reduce the risk of short circuits.

- Improved chemical resistance: Resin impregnation can protect materials from exposure to harsh chemicals and environments.

- Improved water resistance: Resin impregnation can make materials water-resistant or waterproof.

- Enhanced aesthetics: Resin impregnation can improve the appearance of materials and create a glossy or textured finish.

9. What are the typical applications of impregnated materials?

- Electrical components: Insulating and protecting electrical components from moisture and environmental factors.

- Composite materials: Reinforcing and enhancing the strength of composite materials used in aerospace, automotive, and sporting goods.

- Textiles: Waterproofing and flame-proofing fabrics and garments.

- Wood products: Preserving and protecting wood from decay, moisture, and pests.

- Paper and cardboard: Enhancing the strength and durability of paper products.

10. How do you stay up-to-date with the latest advancements in impregnation techniques and materials?

- Attending industry conferences and exhibitions.

- Reading technical articles and journals.

- Consulting with experts and suppliers in the field.

- Participating in online forums and discussion groups.

- Taking continuing education courses or workshops.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Impregnator Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Impregnator Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Impregnator Helper is responsible for assisting the Impregnator in the impregnation process. This includes preparing the fabric, operating the impregnation machine, and inspecting the finished product. The Impregnator Helper must be able to work independently and as part of a team, and must be able to follow instructions carefully.

1. Prepare the fabric

The Impregnator Helper is responsible for preparing the fabric for impregnation. This includes inspecting the fabric for defects, removing any loose threads, and ensuring that the fabric is free of dirt and debris.

- Inspect the fabric for defects

- Remove any loose threads

- Ensure that the fabric is free of dirt and debris

2. Operate the impregnation machine

The Impregnator Helper is responsible for operating the impregnation machine. This includes loading the fabric into the machine, setting the machine controls, and monitoring the impregnation process.

- Load the fabric into the machine

- Set the machine controls

- Monitor the impregnation process

3. Inspect the finished product

The Impregnator Helper is responsible for inspecting the finished product. This includes inspecting the fabric for defects, ensuring that the fabric is properly impregnated, and ensuring that the fabric meets the customer’s specifications.

- Inspect the fabric for defects

- Ensure that the fabric is properly impregnated

- Ensure that the fabric meets the customer’s specifications

4. Other duties

The Impregnator Helper may also be responsible for other duties, such as:

- Cleaning and maintaining the impregnation machine

- Assisting the Impregnator with other tasks, as needed

- Performing other duties, as assigned

Interview Tips

Preparing for an interview for an Impregnator Helper position can help increase your chances of making a positive impression on the interviewer and landing the job. Here are some tips to help you prepare for your interview:

1. Research the company and the position

Before the interview, take some time to research the company and the Impregnator Helper position. This will help you understand the company’s culture, values, and goals, and it will also help you to learn more about the specific responsibilities of the Impregnator Helper position.

- Visit the company’s website

- Read articles about the company in the news

- Talk to people who work at the company

2. Practice answering common interview questions

There are some common interview questions that you are likely to be asked in an interview for an Impregnator Helper position. It is helpful to practice answering these questions beforehand so that you can feel confident and prepared during the interview.

- Tell me about yourself

- Why are you interested in this position

- What are your strengths and weaknesses

3. Prepare questions to ask the interviewer

Asking the interviewer questions at the end of the interview shows that you are interested in the position and that you are engaged in the conversation. It also gives you an opportunity to learn more about the company and the position.

- What are the biggest challenges facing the company right now

- What are the opportunities for advancement within the company

- What is the company culture like

4. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows the interviewer that you are serious about the position and that you respect their time.

- Wear a suit or business casual attire

- Arrive 10-15 minutes early for your interview

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Impregnator Helper, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Impregnator Helper positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.