Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the In-Tube Conversion Technician interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a In-Tube Conversion Technician so you can tailor your answers to impress potential employers.

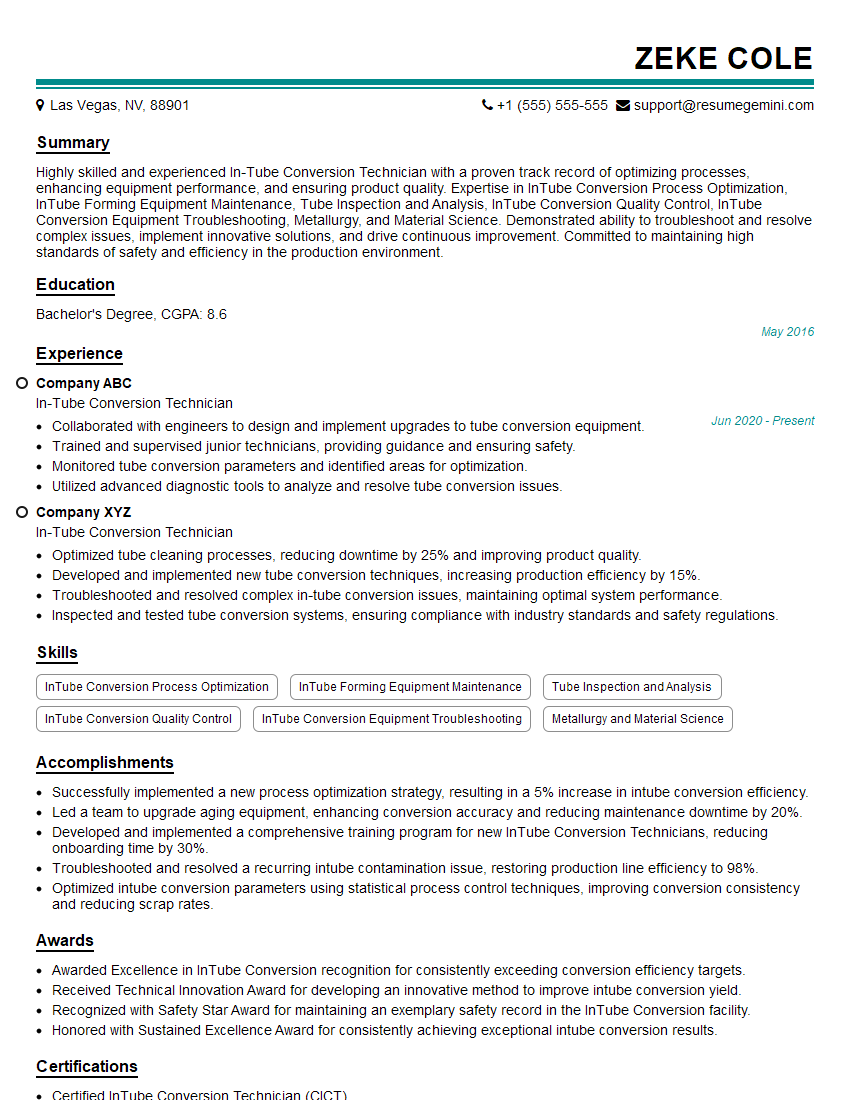

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For In-Tube Conversion Technician

1. Describe the process of In-Tube Conversion.

In-Tube Conversion (ITC) is a process that converts a plastic tube into a smaller tube or rod. This process is commonly used to reduce the diameter of a tube for various applications.

- The plastic tube is first fed into an extruder, which heats and melts the plastic.

- The molten plastic is then forced through a die, which shapes the plastic into a smaller tube or rod.

- The newly formed tube or rod is then cooled and cut to the desired length.

2. What are the different types of In-Tube Conversion machines?

Extrusion machines

- Used to melt and extrude the plastic tube through a die.

- Can be either single-screw or twin-screw extruders.

Die heads

- Shape the molten plastic into the desired tube or rod size.

- Can be made from various materials, such as steel or ceramic.

Cooling systems

- Cool the newly formed tube or rod to solidify it.

- Can use water, air, or a combination of both.

Cutters

- Cut the tube or rod to the desired length.

- Can be either manual or automatic.

3. What are the key parameters that need to be controlled during In-Tube Conversion?

- Temperature: The temperature of the molten plastic must be carefully controlled to ensure proper melting and extrusion.

- Pressure: The pressure applied to the molten plastic must be sufficient to force it through the die.

- Speed: The speed at which the molten plastic is extruded must be controlled to ensure proper shaping and cooling.

4. What are the common defects that can occur during In-Tube Conversion?

- Dimensional errors: The tube or rod may not meet the desired specifications.

- Surface defects: The tube or rod may have scratches, dents, or other surface imperfections.

- Mechanical defects: The tube or rod may not have the desired strength, stiffness, or other mechanical properties.

5. What are the safety precautions that need to be taken when operating an In-Tube Conversion machine?

- Wear appropriate personal protective equipment, such as gloves, safety glasses, and earplugs.

- Keep hands and other body parts away from moving machinery.

- Follow all operating instructions and safety procedures.

6. How do you troubleshoot common problems that can occur during In-Tube Conversion?

- Dimensional errors: Adjust the extrusion speed, pressure, or die temperature.

- Surface defects: Clean the die or extruder head, or adjust the cooling system.

- Mechanical defects: Check the raw material quality, or adjust the extrusion parameters.

7. What are the latest advancements in In-Tube Conversion technology?

- Laser-assisted ITC: Uses a laser to melt and shape the plastic, resulting in higher precision and less waste.

- Multi-layer ITC: Produces tubes or rods with multiple layers of different materials, providing enhanced properties.

- Automated ITC: Integrates sensors and control systems to automate the ITC process, reducing labor costs and increasing efficiency.

8. What are the applications of In-Tube Conversion?

- Medical devices: Catheters, stents, and other implantable devices.

- Automotive: Fuel lines, brake lines, and other fluid carrying components.

- Consumer products: Pens, straws, and other plastic items.

9. What are the advantages of In-Tube Conversion over other tube manufacturing methods?

- High precision: ITC produces tubes with tight tolerances and smooth surfaces.

- Efficient: ITC is a continuous process that can produce long lengths of tubing quickly.

- Versatile: ITC can be used to produce tubes from a wide range of materials, including plastics, metals, and ceramics.

10. What are your strengths and weaknesses as an In-Tube Conversion Technician?

Strengths:

- Thorough understanding of ITC principles and techniques.

- Experience in operating and troubleshooting ITC equipment.

- Strong attention to detail and quality control.

Weaknesses:

- Limited experience with laser-assisted ITC.

- Need to improve communication skills.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for In-Tube Conversion Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the In-Tube Conversion Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An In-Tube Conversion Technician is responsible for the operation, maintenance, and repair of In-Tube Conversion (ITC) systems. ITC systems are used to convert natural gas into hydrogen and carbon dioxide. The technician must have a strong understanding of ITC technology and be able to troubleshoot and repair the systems quickly and efficiently.

1. Operate ITC Systems

The technician must be able to operate ITC systems safely and efficiently. This includes starting and stopping the system, monitoring the system’s performance, and making adjustments as needed.

2. Maintain ITC Systems

The technician must be able to maintain ITC systems in good working order. This includes cleaning the system, replacing filters, and lubricating moving parts.

3. Repair ITC Systems

The technician must be able to troubleshoot and repair ITC systems. This includes identifying the source of the problem, repairing or replacing the damaged parts, and testing the system to ensure that it is working properly.

4. Other Duties

The technician may also be responsible for other duties, such as:

- Training new employees on ITC systems

- Developing and implementing maintenance procedures

- Ordering and inventorying parts

Interview Tips

Preparing for an interview for an In-Tube Conversion Technician position can be daunting, but there are a few things you can do to increase your chances of success.

1. Research the Company

Before your interview, take some time to research the company. This will help you understand the company’s culture, values, and goals. You can also learn more about the specific position you are applying for.

2. Practice Your Answers

Once you have a good understanding of the company and the position, you can start practicing your answers to common interview questions. This will help you feel more confident and prepared during the interview.

3. Be Yourself

The most important thing is to be yourself during the interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Just relax, be honest, and let your personality shine through.

4. Ask Questions

At the end of the interview, be sure to ask the interviewer questions. This shows that you are interested in the position and the company. It also gives you an opportunity to learn more about the company and the position.

Example Outline

Here is an example outline of how you can answer the question “What are your strengths and weaknesses?”

- Strength: I am a highly motivated and results-oriented individual. I am always willing to go the extra mile to get the job done.

- Weakness: I am sometimes too detail-oriented and can get bogged down in the details. I am working on improving this by delegating more tasks and focusing on the big picture.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the In-Tube Conversion Technician interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.