Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Incoming Inspector interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Incoming Inspector so you can tailor your answers to impress potential employers.

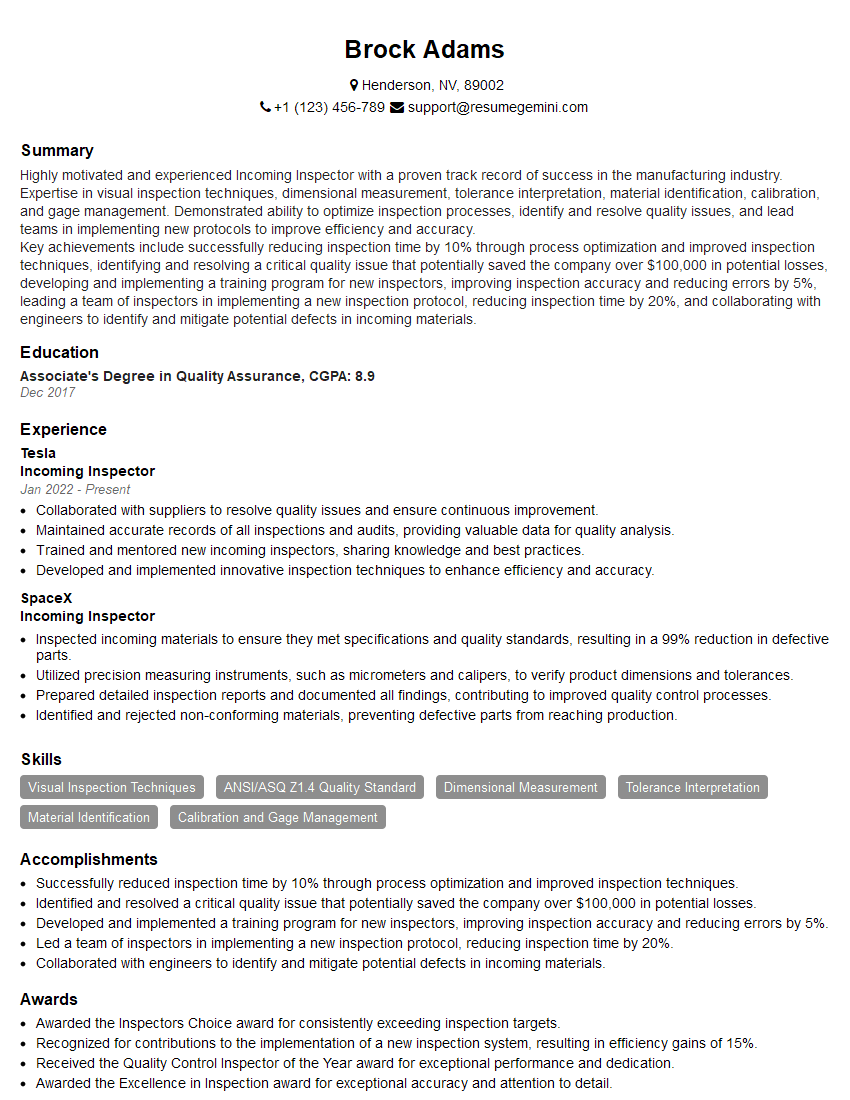

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Incoming Inspector

1. What are the key responsibilities of an Incoming Inspector?

- Inspect incoming raw materials and components to ensure they meet quality standards

- Verify if the received goods matches the purchase order and specifications

- Identify and document any defects or discrepancies

- Maintain accurate records of all inspections performed

- Work closely with suppliers to resolve quality issues

2. What are the qualities and skills required to be a successful Incoming Inspector?

Technical skills

- Strong understanding of quality control principles and practices

- Proficient in using inspection tools and equipment

- Familiarity with relevant industry standards and regulations

Soft skills

- Excellent attention to detail and accuracy

- Strong analytical and problem-solving abilities

- Effective communication and interpersonal skills

3. Describe the typical steps involved in the incoming inspection process.

- Receive and unpack incoming goods

- Verify the quantity and condition of the goods against the packing list or purchase order

- Inspect the goods for any defects or discrepancies, using appropriate inspection tools and techniques

- Document the inspection results, including any defects or discrepancies found

- Take appropriate action based on the inspection results, such as accepting the goods, rejecting them, or requesting further inspection

4. What types of defects and discrepancies do you typically look for during incoming inspection?

- Physical defects, such as scratches, dents, or cracks

- Dimensional defects, such as incorrect size or shape

- Functional defects, such as components that do not work properly

- Missing or incorrect parts or components

- Documentation discrepancies, such as incorrect labels or missing paperwork

5. How do you handle situations where you identify defects or discrepancies during incoming inspection?

- Document the defects or discrepancies in detail, including photographs if necessary

- Notify the supplier immediately and provide them with the inspection results

- Work with the supplier to resolve the issue, such as arranging for a replacement or issuing a credit

- Escalate the issue to management if necessary

6. What is the importance of maintaining accurate inspection records?

- Provide evidence of the inspection process and results

- Help identify trends and patterns in quality issues

- Facilitate communication with suppliers and other stakeholders

- Support continuous improvement efforts

7. How do you stay up-to-date on the latest quality control methods and technologies?

- Attend industry conferences and workshops

- Read trade publications and technical journals

- Network with other quality professionals

- Participate in training and development programs

8. What is your experience with using statistical process control (SPC) techniques?

- I have experience in using SPC techniques such as control charts and capability studies

- I understand the principles of SPC and how to apply them to improve quality

- I have used SPC techniques to identify and reduce variation in manufacturing processes

9. How do you deal with conflicting priorities and deadlines?

- I prioritize tasks based on their importance and urgency

- I communicate my workload and deadlines to my supervisor and team members

- I delegate tasks when necessary

- I work overtime when necessary to meet deadlines

10. Tell me about a time when you had to make a difficult decision.

- I had to decide whether to accept or reject a large shipment of parts that had a minor defect

- I considered the potential risks and benefits of accepting or rejecting the shipment

- I consulted with my supervisor and other stakeholders

- I made a decision that I believe was in the best interests of the company

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Incoming Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Incoming Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Incoming Inspectors play a vital role in the quality assurance of any organization. They are responsible for ensuring that all incoming raw materials, components, and finished goods meet the required standards and specifications.

1. Receiving and Inspecting Goods

Incoming Inspectors are responsible for receiving and inspecting all incoming goods, including raw materials, components, and finished products. They must verify that the goods are complete, undamaged, and in compliance with the purchase order and technical specifications.

- Unpack and inspect incoming goods

- Verify quantity and condition of goods

- Check for damage, defects, or non-conformities

- Compare goods to purchase orders and specifications

2. Documentation and Record Keeping

Incoming Inspectors must maintain accurate and detailed records of all inspections. This includes noting any discrepancies or defects found, as well as the corrective actions taken.

- Record inspection results and findings

- Prepare inspection reports and documentation

- Maintain inspection records for future reference

3. Quality Control and Assurance

Incoming Inspectors play a critical role in ensuring the quality of all incoming goods. They must be able to identify and reject any non-conforming goods, as well as recommend corrective actions to prevent future defects.

- Identify and reject non-conforming goods

- Recommend corrective actions to prevent future defects

- Work with suppliers to improve quality

4. Communication and Teamwork

Incoming Inspectors must be able to communicate effectively with suppliers, production staff, and quality control personnel. They must also be able to work independently and as part of a team.

- Communicate with suppliers and production staff

- Work independently and as part of a team

- Resolve issues and make decisions

Interview Tips

Preparing for an interview for an Incoming Inspector position can help you increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Position

Before the interview, take some time to research the company and the specific Incoming Inspector position. This will help you understand the company’s culture, values, and what they are looking for in a candidate.

- Visit the company’s website

- Read the job description carefully

- Talk to people in your network who work for the company

2. Practice Your Answers

Once you have a good understanding of the company and the position, take some time to practice your answers to common interview questions. This will help you feel more confident and prepared during the interview.

- Common interview questions for Incoming Inspectors include:

- “Tell me about your experience in incoming inspection.”

- “What are the most important qualities of an Incoming Inspector?”

- “How do you handle non-conforming goods?”

3. Prepare Questions to Ask

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position. It also gives you an opportunity to learn more about the company and the position.

- Questions to ask the interviewer include:

- “What are the biggest challenges facing the Incoming Inspection department?”

- “What are the opportunities for growth and advancement within the company?”

- “What is the company’s culture like?”

4. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows the interviewer that you are respectful of their time and that you are serious about the position.

5. Be Confident and Enthusiastic

Confidence and enthusiasm are key during an interview. Believe in yourself and your abilities, and let the interviewer know that you are excited about the opportunity to work for their company.

Next Step:

Now that you’re armed with the knowledge of Incoming Inspector interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Incoming Inspector positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini