Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Induction Brazer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

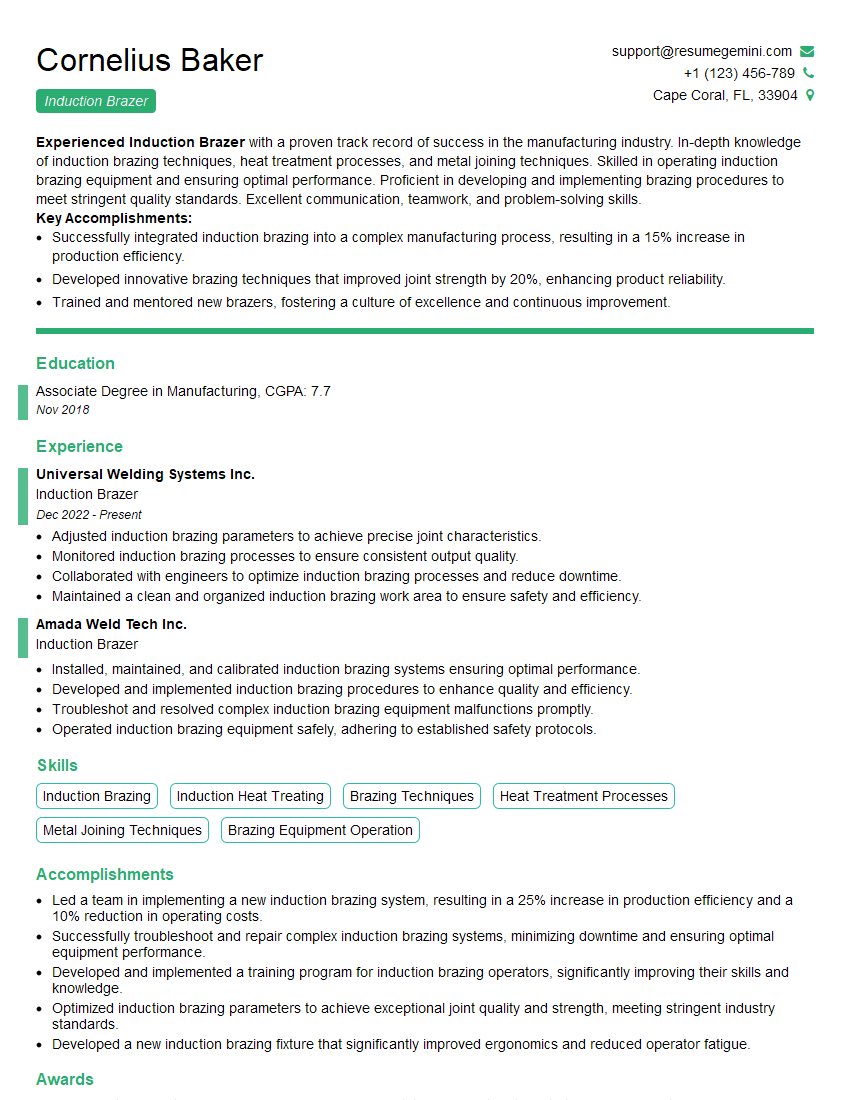

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Induction Brazer

1. Explain the fundamental principles of induction brazing?

Induction brazing is a versatile and efficient metal joining technique that utilizes high-frequency electromagnetic currents to generate controlled localized heat. The process works by passing an alternating current through an induction coil, creating a magnetic field. When a conductive material like metal is placed within this field, eddy currents are induced in the material. These eddy currents generate heat, which melts the filler metal and joins the two metal surfaces together.

- Non-Contact Heating: Induction brazing does not require direct contact with the metal, making it ideal for joining delicate or complex geometries without causing surface damage.

- Fast and Localized Heating: The high-frequency electromagnetic field rapidly heats a localized area, minimizing heat transfer to surrounding components.

- Controlled and Precise: The induction coil’s design and current parameters allow for precise control of the heating zone, resulting in consistent and repeatable joints.

2. Describe the different types of induction brazing equipment and their applications?

Static Induction Brazing Systems

- Stationary induction coils are used for high-volume production where precise heating is required.

- Suitable for complex parts, mass production, and automated processes.

Portable Induction Brazing Systems

- Lightweight and portable induction coils allow for flexibility and easy operation.

- Used for on-site brazing, maintenance, and repair applications.

Scanners and Robotic Induction Brazing Systems

- Advanced systems that use robots or scanners to move the induction coil over the joint area.

- Achieves consistent and precise heating for complex geometries and large-scale production.

3. How do you determine the optimal frequency for induction brazing a specific metal?

The optimal frequency for induction brazing depends on several factors, including the material thickness, shape, and thermal conductivity. Higher frequencies generate higher power densities, resulting in faster heating rates. However, using too high a frequency can lead to skin-effect, where the heat is concentrated on the surface rather than penetrating the material.

- Thicker Materials: Lower frequencies (less than 100 kHz) are suitable for joining thick metal sections, as they allow for deeper penetration of heat.

- Thinner Materials: Higher frequencies (above 100 kHz) are appropriate for brazing thin materials, as they minimize heat diffusion and provide localized heating.

- Thermal Conductivity: Metals with low thermal conductivity, such as copper and silver, require higher frequencies to achieve sufficient heating.

4. Explain the role of flux in induction brazing?

Flux plays a crucial role in induction brazing by removing oxides and impurities from the metal surfaces, promoting wetting and capillary action of the filler metal. It also protects the joint area from oxidation during the heating process.

- Oxidation Removal: Flux reacts with surface oxides, forming a molten slag that floats to the surface and is easily removed.

- Wetting and Capillary Action: Flux reduces surface tension, allowing the molten filler metal to spread evenly and flow into the joint gap.

- Protection from Oxidation: Flux creates a protective layer that prevents oxygen from reaching the joint area, minimizing oxidation and ensuring a clean and strong bond.

5. How do you prevent distortion or damage to the metal during induction brazing?

- Proper Heating: Control the heating rate and duration to minimize thermal stresses and distortion.

- Cooling Jigs and Fixtures: Use fixtures or cooling methods to control the cooling rate and prevent warping.

- Material Selection: Consider the thermal expansion and contraction characteristics of the metals being joined to minimize distortion.

- Induction Coil Design: Optimize the coil design to create a uniform heating pattern and avoid localized overheating.

- Post-Brazing Inspection: Inspect the brazed joint for any distortion or damage using non-destructive testing methods.

6. How do you troubleshoot common induction brazing problems?

- Poor Joint Strength: Inspect for proper flux application, surface preparation, and heating parameters.

- Excessive Heat: Check the power output, coil design, and cooling methods to avoid overheating and distortion.

- Underheating: Verify the frequency selection, power level, and heating duration to ensure sufficient heat penetration.

- Flux Contamination: Ensure the flux is clean and applied correctly to avoid joint contamination.

- Coil Failure: Inspect the coil for damage, corrosion, or overheating, and repair or replace if necessary.

7. What safety precautions are essential when working with induction brazing equipment?

- Electrical Safety: Ensure proper grounding and insulation, and follow electrical safety protocols.

- Eye Protection: Wear appropriate safety glasses or goggles to protect from radiant heat, sparks, and flying debris.

- Heat-Resistant Clothing: Wear protective clothing, gloves, and a face shield to minimize exposure to heat and molten metal.

- Fume Extraction: Use adequate ventilation or fume extraction systems to remove harmful gases and particulates generated during brazing.

- Fire Safety: Have fire extinguishers readily available and follow proper fire safety procedures.

8. Describe the different types of filler metals used in induction brazing and their applications?

- Silver Brazing Alloys: Used for high-strength and high-temperature applications, such as joining stainless steel, copper, and brass.

- Copper-Based Alloys: Suitable for joining copper and copper alloys, providing good electrical conductivity and corrosion resistance.

- Nickel-Based Alloys: Used for demanding applications requiring high strength, corrosion resistance, and oxidation resistance.

- Aluminum-Based Alloys: Used for joining aluminum and aluminum alloys, providing good strength and corrosion resistance.

- Gold Brazing Alloys: Used for specialized applications requiring high temperature resistance and corrosion resistance, such as in jewelry and dental prosthetics.

9. How do you ensure the quality of induction brazed joints?

- Visual Inspection: Inspect the joint for any surface defects, such as voids, cracks, or misalignment.

- Non-Destructive Testing: Use techniques like dye penetrant testing or ultrasonic testing to detect internal defects.

- Mechanical Testing: Perform tensile or shear tests to assess the joint’s strength and integrity.

- Metallurgical Analysis: Examine the joint microstructure to verify proper bonding and absence of defects.

- Quality Control Procedures: Implement quality control measures, such as standardized procedures and documentation, to ensure consistency and reliability.

10. What are the advantages and disadvantages of induction brazing compared to other joining methods?

Advantages:

- Precise and Localized Heating: Controlled heating minimizes heat transfer and distortion.

- Non-Contact Process: No direct contact with the metal prevents surface damage.

- Fast Heating: High-frequency currents enable rapid heating rates.

- High Joint Strength: Induction brazing creates strong and reliable joints.

Disadvantages:

- Higher Initial Investment: Induction brazing equipment requires a significant initial investment.

- Limited Joint Thickness: Induction heating is less effective for joining very thick sections.

- Electrical Hazards: Working with high-voltage currents requires proper safety precautions.

- Skill Requirement: Operating induction brazing equipment requires specialized training and expertise.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Induction Brazer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Induction Brazer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Induction Brazing is a reliable and efficient method of joining metals. The process uses an induction coil to generate a magnetic field around the joint, which then induces an electric current in the metal. This current then heats the metal and melts it, creating a strong bond between the two pieces.

Working as an Induction Brazer comes with various duties and responsibilities. Let’s explore some of these key job responsibilities that are commonly expected:

1. Coil Handling and Maintenance

- Preparing induction coils based on the specific requirements of each brazing job

- Ensuring proper alignment and positioning of coils to optimize heating efficiency

- Regularly inspecting, cleaning, and maintaining induction coils to ensure reliable operation

2. Equipment Operation and Monitoring

- Setting up and operating induction brazing machines according to prescribed procedures

- Monitoring equipment parameters, such as temperature, power, and cycle time, to ensure optimal brazing quality

- Troubleshooting and resolving any technical issues that may arise during the brazing process

3. Joint Preparation and Brazing Process

- Preparing metal surfaces for brazing by cleaning, degreasing, and, if necessary, applying flux

- Positioning and securing workpieces in proper alignment for brazing

- Performing brazing operations, including selecting appropriate brazing alloys and heating cycles

4. Quality Control and Inspection

- Conducting visual inspections and non-destructive testing to verify the quality of brazed joints

- Maintaining accurate records and documentation related to brazing processes and outcomes

- Identifying and addressing any quality issues promptly to maintain high standards

5. Workplace Safety and Compliance

- Adhering to established safety protocols and regulations related to induction brazing operations

- Properly handling and storing hazardous materials, such as brazing alloys and fluxes

- Maintaining a clean and organized work environment to minimize risks and ensure efficiency

In addition to these core responsibilities, Induction Braziers may also be involved in:

- Assisting in the development and improvement of brazing processes

- Training and mentoring new induction brazing operators

- Coordinating with other departments, such as design and production, to ensure seamless integration of brazing operations

Interview Tips

Preparing for an induction brazing interview can be a daunting task, but with the right strategy and by following these tips, you can increase your chances of making a great impression and landing the job.

1. Research the Company and the Job

- Take the time to learn about the company’s history, products or services, and industry standing.

- Review the job description thoroughly to identify the key responsibilities and qualifications required for the role.

- Research industry trends and advancements related to induction brazing to demonstrate your knowledge and enthusiasm.

2. Practice Your Answers

- Anticipate common interview questions and prepare thoughtful responses that highlight your skills and experience.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples.

- Practice your answers out loud to gain confidence and improve your delivery.

3. Dress Professionally and Arrive Punctually

- First impressions matter, so make sure to dress appropriately for the interview, typically business casual or formal attire.

- Plan your route in advance and give yourself ample time to arrive at the interview location without being late.

4. Be Enthusiastic and Confident

- Demonstrate your passion for induction brazing and highlight how your skills align with the company’s needs.

- Maintain eye contact, smile, and actively listen to the interviewer’s questions.

- Be confident in your abilities and articulate your value proposition clearly.

5. Ask Questions

- At the end of the interview, take the opportunity to ask questions about the company, the role, and the induction brazing process.

- This shows your engagement and interest in the position and allows you to gain additional insights.

- Prepare a few thoughtful questions that demonstrate your curiosity and eagerness to learn.

6. Follow Up

- After the interview, send a thank-you note to the interviewer, expressing your appreciation for their time.

- Reiterate your interest in the position and highlight any specific points that you would like to emphasize.

- Inquire about the next steps in the hiring process and follow up if you don’t hear back within a reasonable time.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Induction Brazer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Induction Brazer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.