Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Induction Heat Treater position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

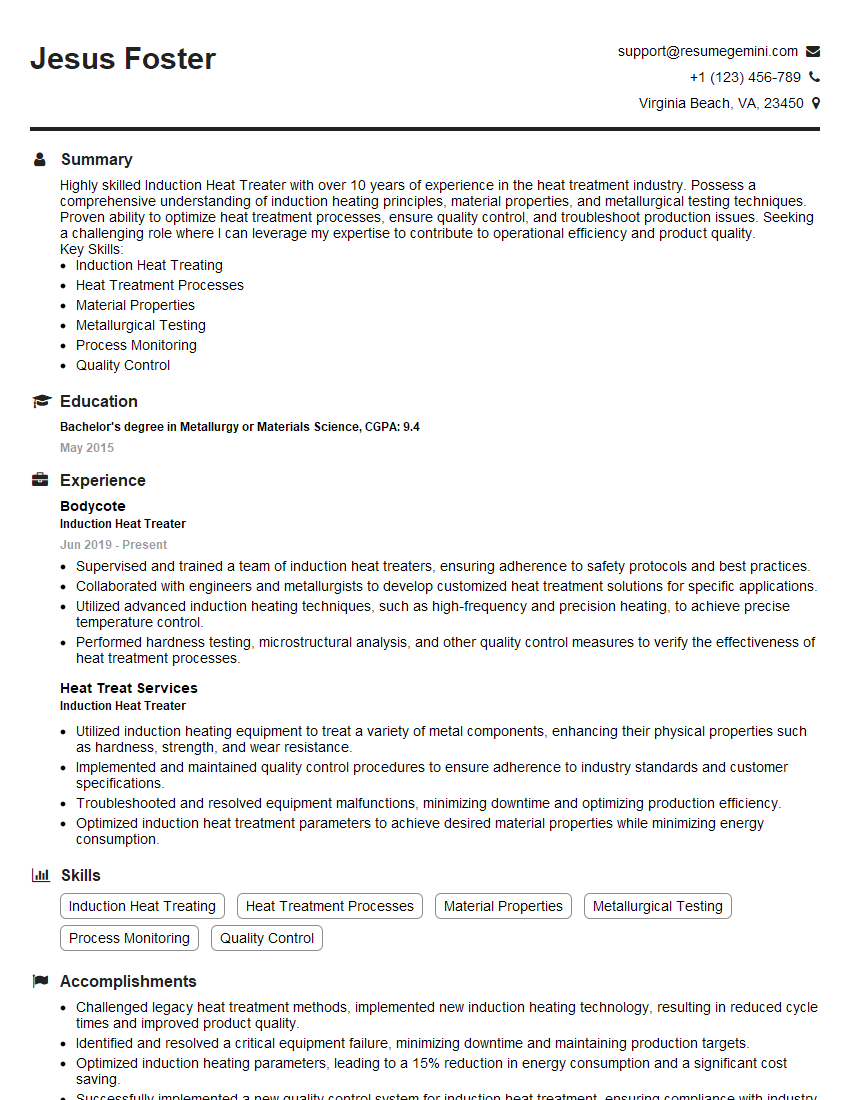

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Induction Heat Treater

1. Explain the principles of induction heat treating and how it differs from other heat treating methods?

Induction heat treating is a non-contact heating process that uses electromagnetic induction to generate heat within a metal workpiece. The workpiece is placed within an alternating current (AC) magnetic field, which induces eddy currents to flow within the metal. These eddy currents generate heat, which is used to heat the workpiece to the desired temperature. Induction heat treating is different from other heat treating methods, such as flame hardening or furnace heating, in that it provides precise, localized heating without the need for direct contact with the heat source.

2. Describe the types of equipment used in induction heat treating and their applications?

Induction Heating Coils

- Custom-designed to match the shape and size of the workpiece

- Made from copper tubing or solid copper

Induction Power Supplies

- Provide the AC current to the induction coil

- Range from low to high frequency depending on the application

Quenching Systems

- Used to rapidly cool the workpiece after heating

- Can be water, oil, or air-based

Temperature Monitoring and Control Systems

- Monitor the temperature of the workpiece during heating

- Ensure accurate and repeatable heating results

3. What are the advantages and disadvantages of using induction heat treating?

- Advantages:

- Precise and localized heating

- Non-contact process, minimizing distortion

- Rapid heating and cooling cycles

- Energy-efficient

- Environmentally friendly

- Disadvantages:

- Limited workpiece size and shape

- Can be expensive to implement

- Requires skilled operators

4. Discuss the factors that affect the induction heat treating process?

- Workpiece geometry and material properties

- Induction coil design and frequency

- Power density and heating time

- Quenching medium and cooling rate

- Temperature monitoring and control

5. Describe the different types of induction coils and their applications?

- Helical Coils: General-purpose coils, suitable for a wide range of shapes

- Pancake Coils: Flat, spiral-shaped coils, used for surface hardening

- Concentric Coils: Used to heat cylindrical workpieces, such as shafts and tubes

- Irregular Coils: Custom-designed coils, used for complex shapes

6. Explain the role of quenching in induction heat treating?

Quenching is a rapid cooling process used to achieve the desired hardness and microstructure in the treated workpiece. The quenching medium (water, oil, or air) is applied to the workpiece immediately after heating, cooling it rapidly to prevent the formation of softer phases. The selection of the quenching medium and cooling rate depends on the material and the desired properties.

7. Describe the methods used to monitor and control the temperature during induction heat treating?

- Infrared Pyrometers: Non-contact temperature measurement devices

- Thermocouples: Contact temperature measurement devices, placed directly on the workpiece

- Induction Heating Power Monitoring: Indirect temperature measurement, based on changes in power consumption

8. Discuss the safety precautions that must be taken when working with induction heat treating equipment?

- Wear appropriate personal protective equipment (PPE)

- Ensure proper grounding and electrical connections

- Handle workpieces carefully, using proper lifting techniques

- Avoid touching the induction coil or workpiece during operation

- Follow established safety protocols and procedures

9. Describe the quality control procedures used in induction heat treating?

- Hardness testing to verify the desired hardness levels

- Microstructure analysis to ensure proper grain structure

- Dimensional inspection to ensure the workpiece meets specifications

- Non-destructive testing methods, such as eddy current testing, to detect surface and subsurface defects

10. What are the emerging trends in induction heat treating technology?

- Use of advanced materials, such as ceramics and composites, for induction coils

- Development of high-frequency and medium-frequency power supplies

- Integration of induction heat treating with other processes, such as additive manufacturing

- Increased automation and process control through digitalization

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Induction Heat Treater.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Induction Heat Treater‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Induction Heat Treater is responsible for operating and maintaining induction heat treating equipment. This equipment is used to heat and harden metal parts. The heat treater must ensure that the parts are heated to the correct temperature and for the correct amount of time. They must also ensure that the parts are properly cooled after being heated. The key job responsibilities of an Induction Heat Treater include:- Operating and maintaining induction heat treating equipment

- Heating and hardening metal parts

- Ensuring that parts are heated to the correct temperature and for the correct amount of time

- Ensuring that parts are properly cooled after being heated

1. Technical Skills

- Expertise in induction heating principles, techniques, and equipment

- Proficient in operating and troubleshooting induction heating systems

- Understanding of part metallurgy and heat treatment processes

- Experience with quality control procedures and specifications

2. Communication and Interpersonal Skills

- Ability to clearly communicate technical information to colleagues, supervisors, and customers

- Excellent teamwork and collaboration skills

- Strong attention to detail and quality assurance

- Capacity to work independently and as part of a team

3. Safety and Compliance

- Thorough knowledge of safety regulations and procedures related to induction heat treating

- Meticulous adherence to safety protocols to ensure both personal and workplace safety

- Active participation in maintaining a clean and organized work environment

- Compliance with environmental regulations and standards

4. Continuous Improvement

- Commitment to ongoing learning and professional development in the field of induction heat treating

- Proactive exploration of new technologies and best practices to enhance efficiency and productivity

- Regular evaluation of processes and implementation of improvements for optimizing operations

- Contribution to the development of innovative solutions for complex heat treatment challenges

Interview Tips

Preparing for an interview for an Induction Heat Treater position requires a combination of technical knowledge, situational awareness, and effective communication skills. Here are some tips to help you ace the interview:1. Research the Company and Position

Thoroughly research the company’s background, industry standing, and specific requirements for the Induction Heat Treater role. This will demonstrate your interest in the position and the company, and allow you to tailor your answers accordingly.2. Highlight Relevant Experience and Skills

Emphasize your technical expertise in induction heating principles, equipment, and processes. Showcase your proficiency in operating and troubleshooting induction heating systems, as well as your understanding of part metallurgy and heat treatment techniques. Provide specific examples of your experience that align with the job responsibilities.3. Prepare for Technical Questions

Anticipate technical questions related to induction heating, such as: – Explain the process of induction hardening. – Describe the factors that affect the depth of hardening in induction heat treating. – How do you troubleshoot common problems encountered in induction heating systems? Prepare well-reasoned answers that demonstrate your understanding and problem-solving abilities.4. Showcase Safety and Compliance Knowledge

Understand the safety regulations and procedures associated with induction heat treating. Be prepared to discuss your commitment to adhering to safety protocols and maintaining a safe work environment. Highlight your knowledge of environmental regulations and standards relevant to the industry.5. Emphasize Continuous Improvement Mindset

Convey your enthusiasm for staying updated with the advancements in induction heat treating. Express your eagerness to learn new technologies and best practices, and contribute to the development of innovative solutions. Showcase your proactive approach to continuous improvement and optimizing operations.6. Prepare Questions for the Interviewer

Ask thoughtful questions during the interview to demonstrate your engagement and interest in the position. This could include inquiries about the company’s long-term goals, induction heating equipment used, or opportunities for professional development.7. Follow Up Professionally

After the interview, promptly follow up with the interviewer to express your gratitude for their time and reiterate your interest in the position. Reiterate your key qualifications and how you can contribute to the company’s success.Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Induction Heat Treater, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Induction Heat Treater positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.