Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Industrial Chemist interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Industrial Chemist so you can tailor your answers to impress potential employers.

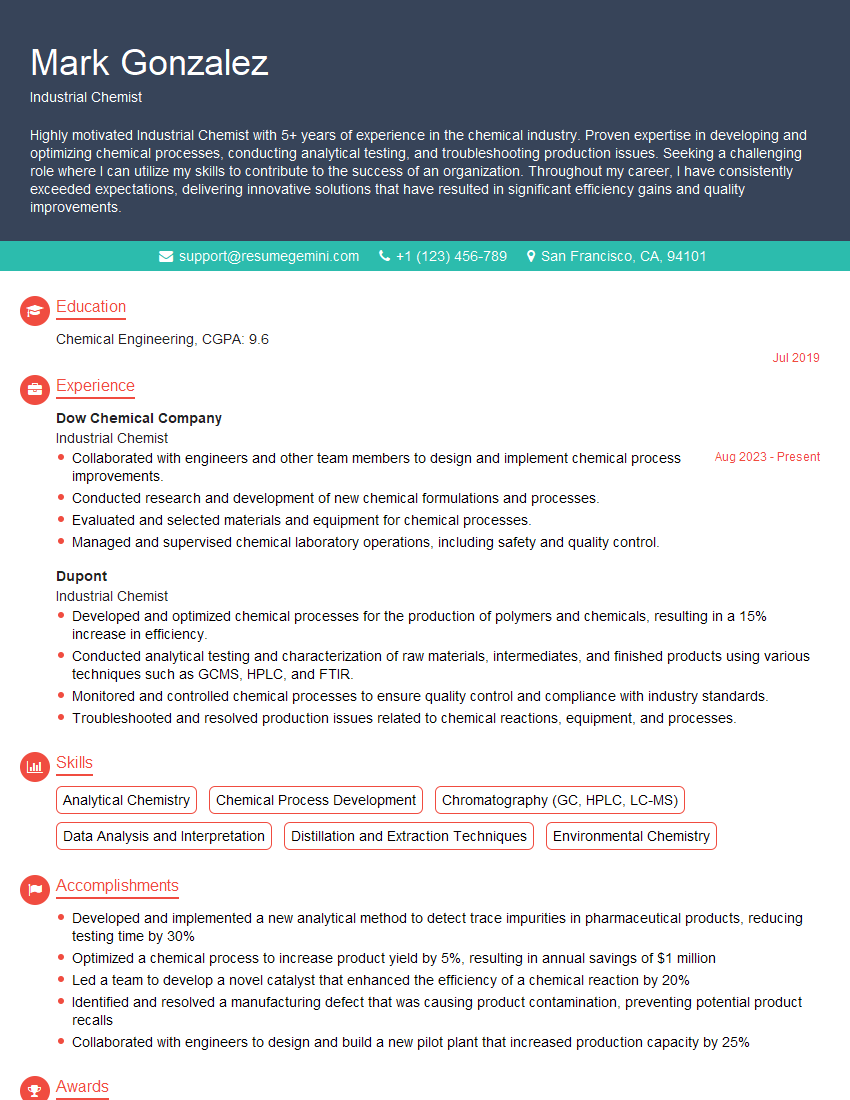

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Industrial Chemist

1. Describe the process of optimizing a chemical reaction for industrial production.

In optimizing a chemical reaction for industrial production, several key steps are involved:

- Define the reaction parameters: Determine the optimal temperature, pressure, and concentration of reactants to maximize yield and selectivity.

- Identify reaction intermediates: Study the reaction mechanism to identify key intermediates and their concentrations to optimize the process.

- Use kinetic modeling: Develop kinetic models to predict reaction rates and product distribution as a function of reaction conditions.

- Experimental validation: Conduct experiments under controlled conditions to validate models and identify any deviations.

- Scale-up optimization: Optimize reaction conditions and equipment design for industrial-scale production, considering factors such as heat transfer and mixing.

2. Explain how chromatography can be used to separate and analyze complex mixtures.

Gel filtration chromatography

- Separates molecules based on their size, with larger molecules eluting first.

- Used for protein purification, DNA/RNA analysis, and size characterization of polymers.

Ion exchange chromatography

- Separates molecules based on their charge, with positively/negatively charged molecules binding/eluting at different salt concentrations.

- Used for protein purification, ion analysis, and desalting.

High-performance liquid chromatography (HPLC)

- Separates molecules based on their interaction with a stationary phase, using different solvents to control elution.

- Used for analyzing small molecules, drugs, and complex mixtures.

3. Describe the principles and applications of spectroscopy in chemical analysis.

Spectroscopy techniques exploit the interaction of electromagnetic radiation with molecules, allowing for the identification and characterization of chemical compounds:

- UV-Vis spectroscopy: Measures the absorption of electromagnetic radiation in the ultraviolet and visible regions, used for identifying functional groups and quantifying compounds.

- Infrared (IR) spectroscopy: Measures the absorption of IR radiation, used for identifying molecular bonds and functional groups.

- Nuclear magnetic resonance (NMR) spectroscopy: Measures the different magnetic environments of atoms, used for structural elucidation and identifying molecular interactions.

- Mass spectrometry: Measures the mass-to-charge ratio of ions, used for identifying and characterizing compounds.

4. Discuss the role of thermodynamics in chemical process design.

Thermodynamics plays a crucial role in chemical process design by providing insights into:

- Reaction feasibility: Predicting the spontaneity and extent of chemical reactions based on entropy and enthalpy changes.

- Process optimization: Identifying the optimal operating conditions to minimize energy consumption and maximize efficiency.

- Equipment design: Selecting appropriate materials and designing heat exchangers, reactors, and other equipment based on thermodynamic properties.

- Safety considerations: Assessing the potential for explosions, fires, and other hazards based on thermodynamic principles.

5. Explain the principles of electrochemistry and its applications in industrial processes.

Electrochemistry involves the study of chemical reactions that occur when an electrical potential is applied:

- Electrolysis: Uses electricity to drive chemical reactions, such as producing chlorine and sodium from brine.

- Electroplating: Uses electricity to deposit a metal coating on a surface, enhancing corrosion resistance and other properties.

- Fuel cells: Generate electricity through electrochemical reactions, offering a clean and efficient energy source.

- Batteries: Store chemical energy electrochemically and release it as electricity, powering electronic devices and electric vehicles.

6. Describe the different types of reactors used in chemical processes and their advantages and disadvantages.

- Batch reactors: Suitable for small-scale production and reactions with high exothermic or endothermic effects.

- Continuous flow reactors: Efficient for large-scale production and reactions with long residence times.

- Plug flow reactors: Provide uniform residence time for all reactants, useful for gas-phase reactions.

- Stirred tank reactors: Create a well-mixed environment, suitable for liquid-phase reactions.

- Bubble column reactors: Used for gas-liquid reactions, where mass transfer is enhanced by bubbles.

7. Discuss the importance of process safety in the chemical industry.

Process safety is paramount in the chemical industry to prevent accidents and ensure the well-being of personnel, the environment, and the community:

- Hazard identification: Identifying potential hazards associated with chemicals and processes.

- Risk assessment: Evaluating the likelihood and consequences of hazards.

- Hazard control: Implementing measures to mitigate risks, such as engineering controls, administrative controls, and personal protective equipment.

- Emergency preparedness: Establishing plans and procedures for responding to emergencies.

- Training: Ensuring employees are aware of process safety hazards and emergency protocols.

8. Explain the principles and applications of chemical kinetics.

Chemical kinetics involves the study of reaction rates and the factors that influence them:

- Reaction rates: Measuring the change in concentration of reactants or products over time.

- Rate laws: Determining the relationship between reaction rate and the concentrations of reactants.

- Activation energy: Understanding the energy barrier that must be overcome for a reaction to occur.

- Catalysis: Exploring the use of catalysts to increase reaction rates.

- Applications: Optimizing chemical processes, designing reactors, and predicting the behavior of chemical systems.

9. Describe the role of an industrial chemist in the development and production of new products.

Industrial chemists play a vital role in the development and production of new products:

- Research and development: Conducting research to identify new chemical compounds and processes, developing prototypes, and testing their feasibility.

- Process optimization: Working with engineers to optimize production processes, improve efficiency, and minimize costs.

- Quality control: Ensuring the consistency and quality of products, testing raw materials and finished products, and implementing quality control procedures.

- Collaboration: Collaborating with scientists, engineers, marketers, and other stakeholders to bring new products to market.

10. How do you stay up-to-date on advancements in the field of industrial chemistry?

To stay up-to-date on advancements in the field of industrial chemistry:

- Attend conferences and workshops: Participating in industry events to learn about new technologies and connect with experts.

- Read scientific journals and publications: Reviewing research papers and articles to stay informed about the latest developments.

- Join professional organizations: Becoming a member of organizations like the American Chemical Society or the Institute of Chemical Engineers provides access to resources and networking opportunities.

- Continuing education courses: Enrolling in courses or workshops to enhance knowledge and skills.

- Online resources: Utilizing websites, online databases, and social media platforms to access information and connect with the scientific community.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Industrial Chemist.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Industrial Chemist‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Industrial Chemists are responsible for a wide range of tasks in the chemical industry. Their primary goal is to develop, test, and improve chemical products and processes.

1. Research and Development

Industrial Chemists conduct research to develop new products and processes. They also work to improve existing products and processes to make them more efficient, cost-effective, and environmentally friendly.

- Design and conduct experiments to test new materials and processes.

- Analyze data to determine the feasibility of new products and processes.

- Develop and improve existing products and processes to enhance their performance and efficiency.

2. Production

Industrial Chemists work in production facilities to ensure that chemical products are manufactured according to specifications. They also monitor the quality of raw materials and finished products.

- Monitor and control chemical reactions to ensure that products are produced according to specifications.

- Troubleshoot production problems and implement corrective actions.

- Ensure that products meet quality standards and regulatory requirements.

3. Quality Control

Industrial Chemists conduct quality control tests to ensure that chemical products meet specifications. They also work to identify and correct any defects in products.

- Develop and implement quality control procedures.

- Conduct tests to ensure that products meet specifications.

- Identify and correct any defects in products.

4. Environmental Compliance

Industrial Chemists must ensure that their work complies with environmental regulations. They work to minimize the environmental impact of chemical production and disposal.

- Develop and implement environmental management plans.

- Monitor and control emissions and waste to minimize environmental impact.

- Ensure that chemical products are disposed of safely and in accordance with regulations.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some tips to help you ace the interview for an Industrial Chemist position:

1. Research the Company

Before the interview, take the time to research the company and the specific position you are applying for. This will help you better understand the company’s culture and goals, as well as the responsibilities of the role.

- Visit the company’s website to learn about its history, mission, and products/services.

- Read industry news and articles to stay up-to-date on the company’s latest developments.

- Connect with current or former employees on LinkedIn to gain insights into the company culture and work environment.

2. Practice Your Answers

Take some time to practice answering common interview questions, such as “Tell me about yourself” and “Why are you interested in this position?” This will help you feel more confident and prepared during the interview.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples of your skills and experiences.

- Focus on highlighting your technical skills and knowledge, as well as your ability to work independently and as part of a team.

- Be prepared to discuss your research experience and how it has prepared you for this role.

3. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing a suit or business casual attire.

- Choose clothing that is clean, pressed, and fits well.

- Avoid wearing clothing that is too revealing or casual.

- Make sure your shoes are clean and polished.

4. Be on Time

Punctuality is important in any professional setting. Be sure to arrive for your interview on time, or even a few minutes early.

- Plan your route in advance and allow for extra time in case of traffic or other delays.

- If you are running late, call the interviewer to let them know.

5. Follow Up

After the interview, be sure to send a thank-you note to the interviewer. This is a great way to reiterate your interest in the position and thank them for their time.

- Send the thank-you note within 24 hours of the interview.

- Keep the note brief and professional.

- Reiterate your interest in the position and thank the interviewer for their time.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Industrial Chemist, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Industrial Chemist positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.