Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Industrial Energy Engineer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

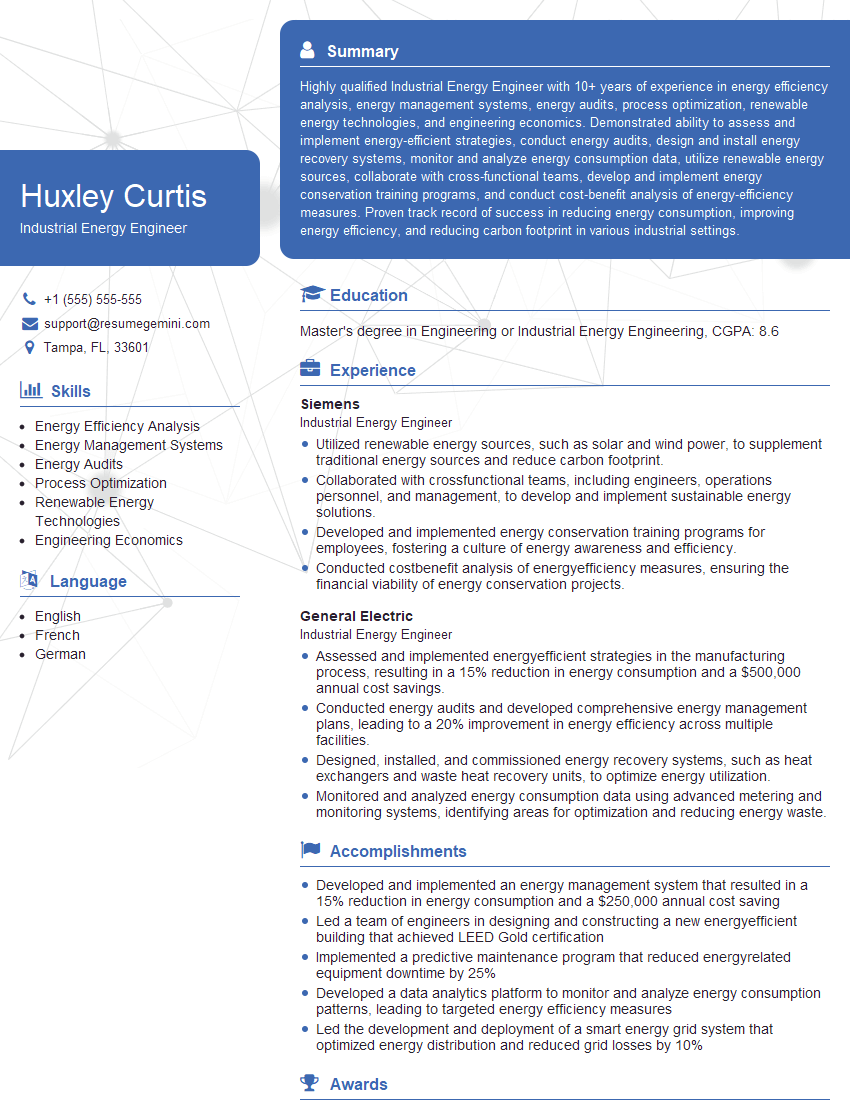

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Industrial Energy Engineer

1. what are the key aspects you consider when conducting an energy audit?

- Gather baseline data: collect historical energy consumption data, equipment inventory, and process information.

- Conduct site walk-through: physically inspect the facility to identify potential energy-saving opportunities.

- Analyze energy data: use statistical tools and energy accounting methods to identify patterns and trends in energy consumption.

- Identify energy conservation measures: evaluate energy-efficient technologies, process optimization techniques, and operational improvements.

- Develop recommendations and implementation plan: outline specific measures, cost estimates, and timelines for implementing energy-saving initiatives.

2. Describe a project where you implemented energy-saving measures in an industrial setting.

Energy efficiency upgrades

- Replaced inefficient lighting fixtures with LED lights.

- Installed variable frequency drives (VFDs) on pumps and fans.

- Implemented motion sensors and timers for lighting and equipment.

Process optimization

- Optimized boiler operations by adjusting combustion parameters.

- Reduced compressed air consumption through leak detection and optimization.

- Improved steam distribution system efficiency by reducing heat losses.

3. Explain the principles and applications of cogeneration systems.

Cogeneration, also known as combined heat and power (CHP), involves generating electricity and useful heat from a single fuel source.

- Principles: Cogeneration systems use a prime mover (e.g., gas turbine, engine) to generate electricity. The waste heat from the prime mover is then captured and used for heating or cooling applications.

- Applications: Cogeneration systems are typically used in industrial facilities, hospitals, and universities where there is a high demand for both electricity and thermal energy. They can significantly reduce energy costs and improve energy efficiency.

4. How do you approach energy modeling and simulation in your work?

- Software selection: Choose appropriate energy modeling software based on project requirements and capabilities.

- Model development: Create a detailed model of the energy system, including equipment characteristics, process flows, and operating conditions.

- Scenario analysis: Run simulations with different scenarios to evaluate energy consumption, costs, and environmental impacts.

- Optimization: Use optimization techniques to identify energy-saving opportunities and optimize system performance.

- Communication: Present simulation results effectively to stakeholders and decision-makers.

5. Describe the role of renewable energy in industrial energy management.

- Emissions reduction: Renewable energy sources, such as solar and wind power, can reduce greenhouse gas emissions and contribute to sustainability goals.

- Energy cost savings: Renewable energy can provide cost-effective electricity and thermal energy, especially in areas with high energy prices.

- Grid resilience: Integrating renewable energy into industrial operations can enhance grid resilience and reduce reliance on fossil fuels.

6. How do you stay up-to-date on emerging technologies and best practices in industrial energy efficiency?

- Attend conferences and industry events.

- Read technical journals and publications.

- Network with other professionals in the field.

- Participate in online webinars and training programs.

- Stay informed about government incentives and regulations related to energy efficiency.

7. Discuss the challenges you have faced in implementing energy-saving projects.

- Technical complexity: Integrating new technologies and systems can be challenging, especially in existing facilities.

- Budget constraints: Energy-saving projects often require significant capital investments, which can be difficult to secure.

- Lack of stakeholder buy-in: It can be challenging to gain support and commitment from all stakeholders involved in energy projects.

8. How do you measure and verify the effectiveness of energy-saving initiatives?

- Monitoring and data collection: Establish a system to monitor energy consumption and other relevant metrics.

- Baseline comparison: Compare energy performance before and after implementing energy-saving measures.

- Statistical analysis: Use statistical methods to determine the significance of energy savings.

- Reporting and communication: Regularly report energy performance data and the results of energy-saving initiatives to stakeholders.

9. Discuss the importance of energy management systems (EMS) in industrial energy efficiency.

- Centralized control: EMS provide a central platform to monitor and control energy consumption across multiple facilities and systems.

- Data analysis: EMS can collect and analyze energy data to identify inefficiencies and opportunities for improvement.

- Automated optimization: EMS can implement automated control strategies to optimize energy consumption based on real-time conditions.

- Reporting and compliance: EMS can generate reports and provide data for compliance with energy regulations and industry standards.

10. How do you prioritize energy-saving opportunities based on their financial and environmental benefits?

- Establish criteria: Define clear criteria for evaluating energy-saving opportunities, including payback period, energy savings, and environmental impact.

- Cost-benefit analysis: Conduct a cost-benefit analysis to determine the financial viability of each opportunity.

- Life cycle assessment: Consider the environmental impacts of energy-saving measures over their entire life cycle.

- Rank and prioritize: Rank energy-saving opportunities based on their financial and environmental benefits, and prioritize those with the highest return on investment and lowest environmental impact.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Industrial Energy Engineer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Industrial Energy Engineer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Industrial Energy Engineers play a critical role in improving energy efficiency, reducing costs, and promoting sustainability within industrial organizations. Their key job responsibilities include:1. Energy Audits and Assessments

Conduct comprehensive energy audits and assessments to identify areas of energy consumption and loss.

- Analyze energy usage data, identify inefficiencies, and develop recommendations for improvement.

- Estimate potential energy savings and cost reductions through various energy conservation measures.

2. Energy Conservation and Optimization

Design and implement energy conservation strategies to reduce energy usage and minimize operating costs.

- Develop and evaluate energy-efficient technologies, processes, and systems.

- Optimize energy distribution systems, including heating, cooling, and lighting, to improve efficiency.

3. Energy Management and Reporting

Develop and implement energy management plans to track energy consumption, monitor performance, and ensure compliance.

- Establish energy performance targets and monitor progress towards those targets.

- Prepare reports and presentations to communicate energy consumption data and improvement initiatives.

4. Sustainability and Environmental Compliance

Integrate energy efficiency initiatives with sustainability and environmental compliance goals.

- Advise on energy-related policies and regulations, ensuring compliance with environmental standards.

- Develop renewable energy and energy storage solutions to reduce reliance on fossil fuels.

Interview Tips

To ace an interview for an Industrial Energy Engineer position, candidates should:1. Research the Company and Industry

Thoroughly research the hiring organization and the energy industry to demonstrate knowledge and interest.

- Review the company’s website, recent news articles, and sustainability reports.

- Stay up-to-date on industry trends and advancements in energy efficiency technologies.

2. Highlight Relevant Skills and Experience

Emphasize transferable skills such as analytical thinking, problem-solving, and data analysis.

- Quantify your accomplishments by providing specific examples of energy audits, projects, or initiatives you’ve led.

- Discuss your understanding of energy codes, standards, and best practices.

3. Prepare for Technical Questions

Be prepared to answer technical questions related to energy systems, energy conservation measures, and energy management tools.

- Review basic energy concepts, such as thermodynamics, heat transfer, and electrical systems.

- Familiarize yourself with energy modeling software and simulation tools commonly used in the industry.

4. Demonstrate Your Passion for Sustainability

Showcase your passion for environmental sustainability and energy efficiency.

- Share examples of your personal or volunteer experiences related to energy conservation or renewable energy.

- Discuss how your values and goals align with the company’s commitment to sustainability.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Industrial Energy Engineer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Industrial Energy Engineer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.