Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Industrial Engineering Analyst position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

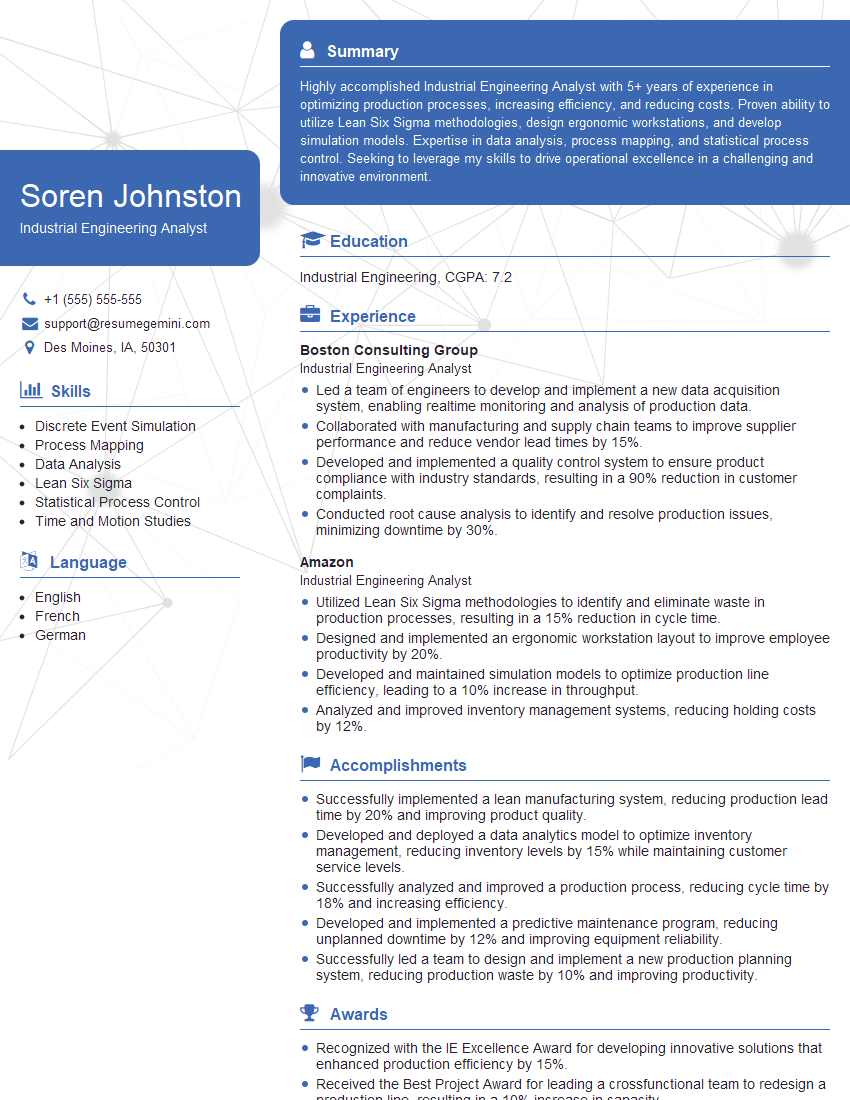

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Industrial Engineering Analyst

1. What are the key responsibilities of an Industrial Engineering Analyst?

As an Industrial Engineering Analyst, my main responsibilities include:

- Conducting time and motion studies to identify and analyze process inefficiencies

- Developing and implementing process improvement plans to streamline operations

- Analyzing production data to identify areas for cost reduction and efficiency gains

- Designing and optimizing production layouts and workflows to maximize efficiency

- Working closely with production teams to identify and resolve production bottlenecks

- Mentoring and training staff on best practices in industrial engineering techniques

2. Can you explain the difference between work measurement and time study?

Work Measurement

- A systematic method for determining the time required to complete a task or operation

- Involves analyzing work methods, estimating time standards, and setting performance targets

Time Study

- A specific method of work measurement that involves observing and recording the time required to complete a task

- Used to determine standard times and identify areas for improvement

3. Describe your experience with lean manufacturing techniques.

I have extensive experience with lean manufacturing techniques, including:

- Value stream mapping

- Kaizen events

- 5S implementation

- Just-in-time (JIT) production

- Single-minute exchange of die (SMED)

I have successfully applied these techniques in various manufacturing environments to reduce waste, improve efficiency, and enhance quality.

4. How do you approach a new process improvement project?

When embarking on a new process improvement project, I follow a structured approach that involves the following steps:

- Define the problem and set clear goals

- Gather data and analyze the current process

- Develop and evaluate potential solutions

- Implement the best solution and monitor its impact

- Make adjustments as needed to ensure continuous improvement

5. What is your experience with statistical process control (SPC)?

I have a strong understanding of SPC and have applied it in various manufacturing settings to:

- Monitor and control production processes

- Identify and reduce process variability

- Improve product quality and consistency

I am proficient in using SPC tools such as control charts, histograms, and Pareto charts.

6. Can you describe a situation where you successfully improved a production process?

In my previous role, I was responsible for improving the efficiency of a production line that was experiencing excessive downtime. I conducted a time study and identified that the main bottleneck was in the assembly process. I redesigned the assembly process, implemented a new workflow, and trained the operators on improved methods. As a result, the line’s production rate increased by 15%, and downtime was reduced by 30%.

7. How do you stay up-to-date with the latest trends in industrial engineering?

I stay up-to-date with the latest trends in industrial engineering through various methods:

- Attending industry conferences and workshops

- Reading technical journals and publications

- Participating in online forums and discussion groups

- Pursuing continuing education courses

8. What are your strengths and weaknesses as an Industrial Engineering Analyst?

Strengths

- Excellent analytical and problem-solving skills

- Strong understanding of lean manufacturing techniques

- Proficient in using SPC tools and techniques

- Experience in developing and implementing process improvement plans

- Excellent communication and interpersonal skills

Weaknesses

- Limited experience in the automotive industry

- Working on projects with tight deadlines can sometimes be stressful

9. What are your salary expectations?

My salary expectations are in line with the industry average for similar roles. I am open to discussing compensation based on the specific responsibilities and scope of the position.

10. Do you have any questions for me?

I would like to ask about the company’s commitment to continuous improvement. I am particularly interested in learning about any specific initiatives or programs that are in place to foster innovation and efficiency.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Industrial Engineering Analyst.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Industrial Engineering Analyst‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Industrial Engineering Analysts play a pivotal role in optimizing processes and improving efficiency within organizations. Their responsibilities encompass a wide range of tasks:

1. Process Analysis and Improvement

They analyze existing processes, identify bottlenecks and inefficiencies, and develop solutions to enhance productivity.

- Conduct time and motion studies to determine process efficiency.

- Implement lean manufacturing principles to reduce waste and improve flow.

2. Data Collection and Analysis

Analysts gather and analyze data from various sources, including production records, equipment performance metrics, and customer feedback, to identify trends and areas for optimization.

- Develop and implement data collection systems to track process performance.

- Use statistical techniques to analyze data and identify patterns and correlations.

3. System Design and Implementation

Based on their analysis, they design and implement new or improved systems, including production lines, inventory management systems, and quality control procedures.

- Create workflow diagrams and process maps to visualize and optimize processes.

- Collaborate with cross-functional teams to implement new systems and monitor their performance.

4. Training and Development

Analysts provide training to employees on new processes and systems to ensure their effective implementation.

- Develop and deliver training materials on process improvement techniques.

- Mentor employees and provide guidance on process optimization.

Interview Tips

To ace the Industrial Engineering Analyst interview, candidates should:

1. Showcase Strong Analytical Skills

Highlight your ability to analyze data, identify patterns, and develop data-driven solutions.

- Provide examples of projects where you successfully used analytical techniques to solve problems.

- Discuss your understanding of statistical methods and how you apply them in your work.

2. Demonstrate Process Improvement Expertise

Emphasize your experience in process analysis, optimization, and implementation.

- Describe specific instances where you improved processes and achieved tangible results.

- Explain your knowledge of lean manufacturing principles and how you have applied them to enhance efficiency.

3. Prepare for Technical Questions

Be prepared to answer questions about industrial engineering principles, data analysis tools, and process modeling techniques.

- Review your engineering coursework and brush up on key concepts.

- Practice using industry-standard software for data analysis and process simulation.

4. Highlight Communication and Teamwork Skills

Industrial Engineering Analysts work closely with cross-functional teams. Showcase your ability to communicate effectively and collaborate with others.

- Provide examples of projects where you successfully collaborated with colleagues from different departments.

- Demonstrate your ability to present complex technical information in a clear and concise manner.

5. Research the Company and Industry

Familiarize yourself with the company’s products, services, and industry trends. This will enable you to ask informed questions and show that you are genuinely interested in the role.

- Review the company’s website, annual reports, and news articles.

- Study industry publications and reports to stay up-to-date on the latest advancements in industrial engineering.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Industrial Engineering Analyst interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!