Are you gearing up for an interview for a Industrial Equipment Assembler and Wirer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Industrial Equipment Assembler and Wirer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

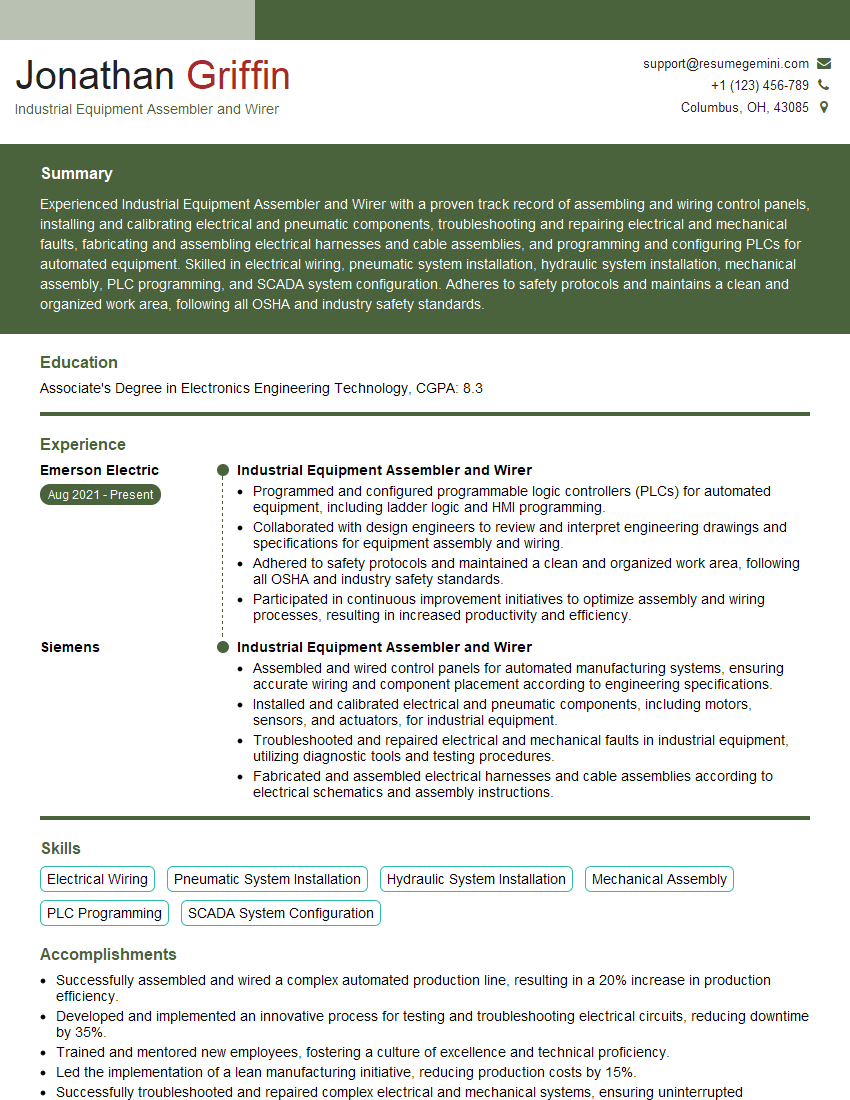

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Industrial Equipment Assembler and Wirer

1. What are the electrical components that you are familiar with?

I have hands-on experience with various electrical components such as resistors, capacitors, inductors, transistors, diodes, and integrated circuits.

2. Describe the process of assembling an industrial motor

Wire connection

- Identify the motor terminals and connect the wires according to the wiring diagram.

- Ensure proper insulation and strain relief for the wire connections.

Bearing installation

- Fit the bearings into the motor housing, ensuring correct alignment and lubrication.

- Secure the bearings with retaining rings or other appropriate methods.

Rotor and stator assembly

- Insert the rotor into the stator, aligning the components accurately.

- Secure the rotor using retaining rings or screws.

End caps and shaft installation

- Install the end caps on both sides of the motor, ensuring proper alignment and seals.

- Insert the shaft into the motor housing and secure it with the appropriate hardware.

Final assembly and testing

- Complete the assembly by securing all components and checking for proper operation.

- Run the motor to verify its functionality and performance.

3. How do you ensure the accuracy of your wiring work?

I adhere to the following steps to ensure the accuracy of my wiring work:

1. I carefully study the wiring diagrams to understand the intended circuit.

2. I meticulously double-check the wire connections against the diagrams.

3. I use precision tools and techniques to ensure proper connections and insulation.

4. I conduct thorough testing and troubleshooting to verify the functionality of the wiring.

4. What are the safety precautions you take when working with high-voltage equipment?

When working with high-voltage equipment, I prioritize the following safety precautions:

1. I wear appropriate personal protective equipment (PPE), including insulated gloves, sleeves, and headgear.

2. I ensure the work area is well-ventilated and free from flammable materials.

3. I use insulated tools and equipment to minimize the risk of electrical shock.

4. I establish a clear work zone and restrict access to unauthorized personnel.

5. How do you troubleshoot electrical faults in industrial equipment?

To troubleshoot electrical faults in industrial equipment, I follow a systematic approach:

1. Visual Inspection – I examine the equipment for any visible damage or loose connections.

2. Electrical Testing – I use multimeters and other diagnostic tools to test for continuity, voltage, and current.

3. Circuit Analysis – I analyze the circuit diagrams to identify potential fault points.

4. Component Inspection – I remove and inspect individual components, such as resistors, capacitors, and transistors, for damage or defects.

5. Repair and Replacement – Once the fault is identified, I repair or replace the faulty components and reassemble the equipment.

6. What is the importance of grounding in electrical systems?

Grounding in electrical systems serves several crucial purposes:

1. Safety – Grounding provides a low-resistance path for fault currents to flow, protecting personnel from electrical shock.

2. Electrical Stability – Grounding ensures a stable voltage reference, preventing voltage fluctuations and equipment damage.

3. Noise Reduction – Grounding helps to dissipate electrical noise and interference, improving the performance and reliability of electronic devices.

4. Lightning Protection – Proper grounding provides a safe path for lightning surges to dissipate into the earth, minimizing damage to equipment and buildings.

7. What is your experience with using electrical design software?

I am proficient in using electrical design software such as AutoCAD Electrical, EPLAN, and SolidWorks Electrical. I have utilized these tools to create schematics, panel layouts, and wire lists for industrial equipment. My experience with these software enables me to efficiently design and document electrical systems.

8. How do you stay up-to-date with the latest electrical codes and standards?

To stay abreast of the latest electrical codes and standards, I regularly engage in the following practices:

1. Reading Industry Publications – I subscribe to industry magazines and journals to keep informed about new regulations and best practices.

2. Attending Conferences and Workshops – I participate in industry events to learn from experts and network with professionals in the field.

3. Online Resources – I utilize online resources such as the National Electrical Code website and professional organization websites for up-to-date information.

4. Continuing Education – I pursue ongoing education courses and certifications to enhance my knowledge and skills in accordance with evolving codes and standards.

9. Can you explain the concept of power factor and its significance?

Power factor is a measure of the efficiency of power transmission in an AC circuit. It represents the ratio of real power (measured in watts) to apparent power (measured in volt-amperes). A power factor of 1 indicates that all the power is being used for productive work, while a lower power factor signifies that some of the power is being consumed as reactive power. Improving power factor reduces energy losses, increases equipment efficiency, and can lead to cost savings.

10. What are the different types of wire insulation materials commonly used in industrial wiring?

Industrial wiring employs various types of insulation materials to protect conductors and ensure safe operation. Some common insulation materials include:

1. PVC (Polyvinyl Chloride) – Provides good electrical insulation, flame resistance, and flexibility.

2. XLPE (Cross-Linked Polyethylene) – Offers excellent electrical properties, high temperature resistance, and moisture resistance.

3. EPR (Ethylene Propylene Rubber) – Exhibits good flexibility, ozone resistance, and resistance to chemicals and oils.

4. Silicone Rubber – Known for its high-temperature tolerance, flexibility, and resistance to harsh environments.

5. FEP (Fluorinated Ethylene Propylene) – Provides exceptional chemical resistance, low friction, and high temperature stability.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Industrial Equipment Assembler and Wirer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Industrial Equipment Assembler and Wirer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Industrial Equipment Assemblers and Wirers play a crucial role in the manufacturing industry, ensuring the safe and efficient assembly and wiring of various types of industrial equipment. Their responsibilities encompass a wide range of tasks, including:

1. Equipment Assembly

Assembling components and subassemblies of industrial equipment such as machinery, robots, conveyor systems, and electrical panels.

- Interpreting blueprints, schematics, and work orders to determine assembly specifications.

- Using hand tools, power tools, and welding equipment to join and assemble components.

2. Wiring and Electrical Installation

Installing and connecting electrical components, wires, and cables within industrial equipment.

- Reading and interpreting electrical diagrams to identify wiring requirements.

- Installing electrical components such as transformers, circuit breakers, and motors.

- Routing and connecting wires and cables to ensure proper electrical functionality.

3. Equipment Testing and Troubleshooting

Testing assembled equipment to verify functionality and identify potential issues.

- Using test equipment and diagnostic tools to evaluate electrical and mechanical performance.

- Identifying and troubleshooting electrical and mechanical problems, and making necessary adjustments or repairs.

4. Quality Assurance and Documentation

Ensuring the quality of assembled equipment and maintaining accurate documentation.

- Inspecting assembled equipment for defects and adherence to specifications.

- Maintaining assembly records, work orders, and other relevant documentation.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some tips to help you ace your interview for an Industrial Equipment Assembler and Wirer position:

1. Research the Company and Position

Familiarize yourself with the company’s background, products, and services. Research the specific role you are applying for and its responsibilities. This knowledge will help you answer questions intelligently and demonstrate your interest in the position.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills in equipment assembly, wiring, electrical installation, and troubleshooting. Quantify your experience by providing specific examples of projects you have worked on and the outcomes you achieved. Use action verbs and highlight your proficiency in using relevant tools and equipment.

3. Demonstrate Problem-Solving Abilities

Interviewers will be interested in your ability to solve problems and make decisions. Prepare examples of situations where you identified and resolved electrical or mechanical issues in previous roles. Explain your thought process and the steps you took to find solutions.

4. Show Teamwork and Communication Skills

Industrial Equipment Assemblers and Wirers often work in teams. Highlight your ability to collaborate effectively with colleagues and communicate clearly with supervisors and clients. Provide examples of projects where you successfully worked as part of a team and contributed to the team’s success.

5. Prepare for Common Interview Questions

Anticipate common interview questions such as “Tell me about yourself,” “Why are you interested in this position?” and “What are your strengths and weaknesses?” Practice your answers to these questions in advance to deliver clear and concise responses.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Industrial Equipment Assembler and Wirer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.