Are you gearing up for an interview for a Industrial Equipment Wirer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Industrial Equipment Wirer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

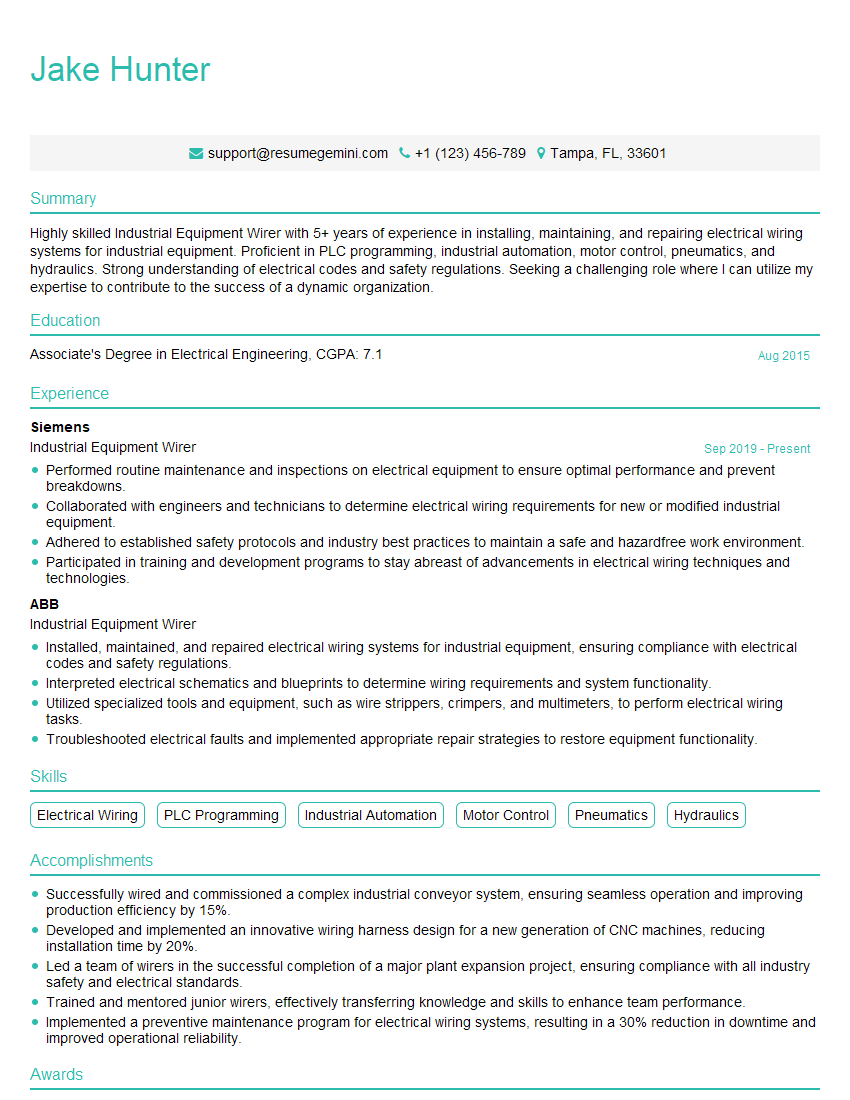

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Industrial Equipment Wirer

1. What are the common types of electrical wiring used in industrial equipment?

- Conductors: These are the wires that carry electricity. They can be made of copper, aluminum, or other materials.

- Insulation: This is the material that surrounds the conductors and prevents them from touching each other. It can be made of rubber, plastic, or other materials.

- Sheathing: This is the outermost layer of the wiring and protects it from damage. It can be made of metal, plastic, or other materials.

2. What are the different types of electrical connections used in industrial equipment?

Terminals

- Screw terminals: These are the most common type of terminal and are used to connect wires to electrical devices.

- Spring terminals: These are a type of terminal that uses a spring to hold the wire in place. They are often used in applications where the wire may need to be disconnected frequently.

- Crimp terminals: These are a type of terminal that is crimped onto the wire. They are often used in applications where the wire will not need to be disconnected.

Splices

- Soldered splices: These are a type of splice that is created by soldering the wires together. They are often used in applications where the splice will not need to be disconnected.

- Crimped splices: These are a type of splice that is created by crimping the wires together. They are often used in applications where the splice will need to be disconnected frequently.

3. What are the different types of electrical components used in industrial equipment?

- Resistors: These are components that resist the flow of electricity. They are used to control the amount of current that flows through a circuit.

- Capacitors: These are components that store electrical energy. They are used to smooth out the flow of electricity in a circuit.

- Inductors: These are components that store magnetic energy. They are used to protect circuits from voltage spikes.

- Transformers: These are components that change the voltage of electricity. They are used to power devices that require different voltages.

- Motors: These are components that convert electrical energy into mechanical energy. They are used to power machines and other devices.

4. What are the different types of electrical tools used in industrial equipment?

- Multimeters: These are devices that measure electrical properties such as voltage, current, and resistance.

- Oscilloscopes: These are devices that display electrical signals over time. They are used to troubleshoot electrical circuits.

- Clamp meters: These are devices that measure the current flowing through a wire without having to break the circuit.

- Insulation testers: These are devices that measure the resistance of insulation to ensure that it is not damaged.

- Ground testers: These are devices that measure the resistance of a ground connection to ensure that it is properly grounded.

5. What are the different types of electrical safety precautions that must be taken when working on industrial equipment?

- Lock out/tag out: This is a procedure that is used to ensure that equipment is not energized while it is being worked on.

- Grounding: This is a procedure that is used to protect workers from electrical shock by connecting the equipment to a ground.

- Insulation: This is a material that is used to protect workers from electrical shock by preventing them from coming into contact with live wires.

- Personal protective equipment (PPE): This is equipment that is worn by workers to protect them from electrical shock, arc flash, and other hazards.

6. What are the different types of troubleshooting techniques that can be used to identify and repair electrical problems in industrial equipment?

- Visual inspection: This is a technique that involves looking for any obvious signs of damage, such as loose wires, damaged insulation, or burnt components.

- Electrical testing: This is a technique that involves using electrical test equipment to measure electrical properties such as voltage, current, and resistance.

- Schematic reading: This is a technique that involves using a schematic diagram to trace the flow of electricity through a circuit and identify potential problems.

- Signal tracing: This is a technique that involves using an oscilloscope to trace the flow of electrical signals through a circuit and identify potential problems.

- Component replacement: This is a technique that involves replacing damaged or faulty components with new ones.

7. What are the different types of maintenance procedures that can be performed on industrial equipment to prevent electrical problems?

- Preventive maintenance: This is a type of maintenance that is performed on a regular schedule to prevent electrical problems from occurring.

- Predictive maintenance: This is a type of maintenance that is performed based on the condition of the equipment, as determined by monitoring its performance.

- Corrective maintenance: This is a type of maintenance that is performed to repair electrical problems after they have occurred.

8. What are the different types of electrical codes and standards that apply to industrial equipment?

- National Electrical Code (NEC): This is a code that sets the minimum requirements for the installation and maintenance of electrical systems in the United States.

- International Electrotechnical Commission (IEC) standards: These are standards that set the requirements for the design, construction, and testing of electrical equipment.

- Occupational Safety and Health Administration (OSHA) regulations: These are regulations that set the requirements for the safety of workers who work with electrical equipment.

9. What are the different types of certifications that are available for industrial equipment wirers?

- Journeyman electrician: This is a certification that is required for electricians who work on industrial equipment.

- Master electrician: This is a certification that is required for electricians who supervise other electricians.

- Certified Electrical Maintenance Technician (CEMT): This is a certification that is offered by the National Institute for Certification in Engineering Technologies (NICET).

10. What are the different types of career opportunities that are available for industrial equipment wirers?

- Industrial electrician: This is a position that involves working on the electrical systems of industrial equipment.

- Maintenance electrician: This is a position that involves maintaining the electrical systems of industrial equipment.

- Construction electrician: This is a position that involves working on the electrical systems of industrial buildings.

- Project manager: This is a position that involves overseeing the installation and maintenance of electrical systems in industrial facilities.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Industrial Equipment Wirer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Industrial Equipment Wirer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Industrial Equipment Wirers are responsible for the installation, maintenance, and repair of electrical wiring and equipment in industrial settings. They work in a variety of industries, including manufacturing, construction, and transportation.

1. Electrical Wiring Installation

Industrial Equipment Wirers install electrical wiring and equipment according to blueprints and specifications. They must be familiar with the National Electrical Code (NEC) and other applicable codes and regulations.

- Read and interpret blueprints and schematics

- Install electrical conduit and wiring

- Connect electrical components, such as motors, switches, and transformers

2. Electrical Equipment Maintenance

Industrial Equipment Wirers perform regular maintenance on electrical equipment to ensure that it is operating safely and efficiently. They may also troubleshoot and repair electrical problems.

- Inspect electrical equipment for signs of wear or damage

- Clean and lubricate electrical components

- Test electrical equipment to ensure that it is operating properly

3. Electrical Equipment Repair

Industrial Equipment Wirers repair electrical equipment that has malfunctioned. They may replace damaged components, such as fuses, circuit breakers, and motors.

- Troubleshoot electrical problems

- Replace damaged electrical components

- Repair electrical equipment to manufacturer’s specifications

4. Safety

Industrial Equipment Wirers must follow all safety procedures when working on electrical equipment. They must wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and hard hats.

- Follow all safety procedures when working on electrical equipment

- Wear appropriate personal protective equipment (PPE)

- Be aware of potential hazards, such as electrical shock and arc flash

Interview Tips

To ace your interview for an Industrial Equipment Wirer position, it is important to be prepared. Here are a few tips to help you succeed:

1. Research the company and the position

Before your interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture and values, as well as the specific skills and experience they are looking for in a candidate.

- Visit the company’s website

- Read articles about the company in industry publications

- Talk to people in your network who work for the company

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Use the STAR method to answer behavioral interview questions

- Be specific and provide examples

- Tailor your answers to the specific position you are applying for

3. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally for your interview. You should also arrive on time, or even a few minutes early. This shows that you are respectful of the interviewer’s time and that you are serious about the position.

- Wear a suit or business casual attire

- Make sure your clothes are clean and pressed

- Arrive on time, or even a few minutes early

4. Be prepared to ask questions

At the end of the interview, the interviewer will likely ask you if you have any questions. This is your opportunity to learn more about the position and the company. It is also a chance for you to show that you are interested and engaged.

- Ask questions about the company culture

- Ask questions about the specific position

- Ask questions about the interviewer’s experience

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Industrial Equipment Wirer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!