Are you gearing up for a career in Industrial Gas Fitter Helper? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Industrial Gas Fitter Helper and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

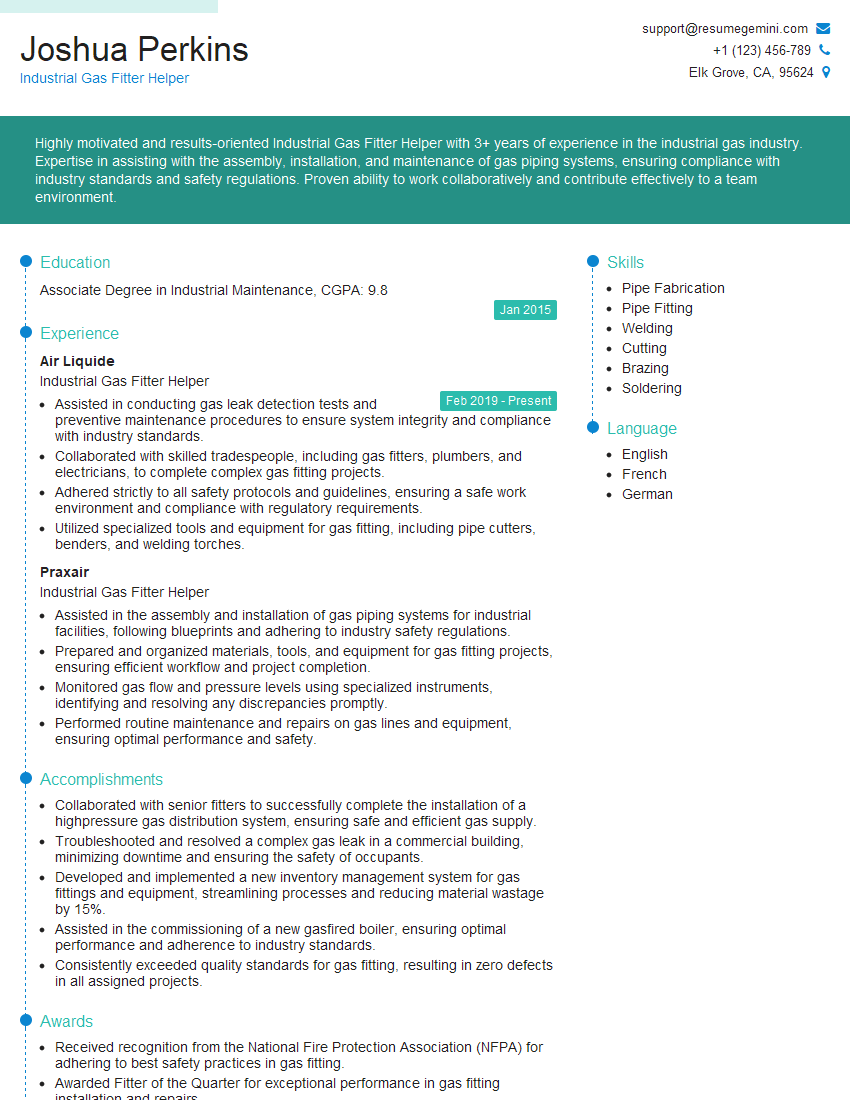

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Industrial Gas Fitter Helper

1. Explain the different types of gas piping systems used in industrial settings?

There are various types of gas piping systems used in industrial settings, including:

- High-pressure systems: These systems operate at pressures above 15 psi (1 bar) and are typically used for distribution of natural gas, propane, or other fuel gases.

- Medium-pressure systems: These systems operate at pressures between 5 and 15 psi (0.3-1 bar) and are used for distribution of industrial gases, such as oxygen, nitrogen, and argon.

- Low-pressure systems: These systems operate at pressures below 5 psi (0.3 bar) and are used for distribution of fuel gases to appliances and equipment.

2. What are the key safety considerations when working with industrial gas piping systems?

General Safety Precautions

- Always wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and hearing protection.

- Never smoke or use open flames near gas piping systems.

- Be aware of the potential for leaks and take appropriate precautions to prevent gas buildup.

- Regularly inspect gas piping systems for any signs of leaks or damage.

Specific Safety Considerations for High-Pressure Gas Systems

- Only qualified personnel should work on high-pressure gas piping systems.

- High-pressure gas piping systems should be regularly inspected and tested for leaks.

- Pressure relief devices should be installed on high-pressure gas piping systems to prevent over-pressurization.

3. Describe the process of installing a new gas piping system in an industrial facility.

The process of installing a new gas piping system in an industrial facility typically involves the following steps:

- Planning: The first step is to plan the layout of the gas piping system, including the location of pipes, fittings, and valves.

- Materials procurement: The next step is to procure the necessary materials, including pipes, fittings, valves, and other components.

- Installation: The pipes and fittings are then installed according to the plan, using appropriate tools and techniques.

- Testing: Once the gas piping system is installed, it must be tested for leaks and proper operation.

- Commissioning: The final step is to commission the gas piping system and put it into operation.

4. What are the different types of gas fittings used in industrial gas piping systems?

There are various types of gas fittings used in industrial gas piping systems, including:

- Elbows: Used to change the direction of a pipe.

- Tees: Used to connect three pipes together.

- Reducers: Used to connect pipes of different diameters.

- Caps: Used to close off the end of a pipe.

- Unions: Used to connect two pipes together in a way that allows for easy disassembly.

5. Describe the different types of valves used in industrial gas piping systems.

There are various types of valves used in industrial gas piping systems, including:

- Gate valves: Used to completely shut off the flow of gas.

- Globe valves: Used to regulate the flow of gas.

- Check valves: Used to prevent the backflow of gas.

- Pressure relief valves: Used to protect the gas piping system from over-pressurization.

6. What are the different types of gas regulators used in industrial gas piping systems?

There are various types of gas regulators used in industrial gas piping systems, including:

- Pressure regulators: Used to reduce the pressure of gas.

- Flow regulators: Used to control the flow of gas.

- Back pressure regulators: Used to maintain a constant pressure on the downstream side of the regulator.

7. What are the different types of gas meters used in industrial gas piping systems?

There are various types of gas meters used in industrial gas piping systems, including:

- Positive displacement meters: Used to measure the volume of gas that passes through them.

- Turbine meters: Used to measure the flow rate of gas.

- Ultrasonic meters: Used to measure the flow rate and velocity of gas.

8. What are the different types of gas sensors used in industrial gas piping systems?

There are various types of gas sensors used in industrial gas piping systems, including:

- Combustible gas sensors: Used to detect the presence of combustible gases, such as natural gas, propane, and butane.

- Toxic gas sensors: Used to detect the presence of toxic gases, such as carbon monoxide, hydrogen sulfide, and ammonia.

- Oxygen sensors: Used to measure the concentration of oxygen in the air.

9. What are the different types of gas leak detection systems used in industrial gas piping systems?

There are various types of gas leak detection systems used in industrial gas piping systems, including:

- Fixed gas detectors: Used to continuously monitor the air for the presence of gas leaks.

- Portable gas detectors: Used to manually check for gas leaks.

- Infrared cameras: Used to visually detect gas leaks.

10. What are the different types of gas safety systems used in industrial gas piping systems?

There are various types of gas safety systems used in industrial gas piping systems, including:

- Emergency shut-off valves: Used to automatically shut off the flow of gas in the event of a leak or other emergency.

- Pressure relief devices: Used to protect the gas piping system from over-pressurization.

- Gas detection and alarm systems: Used to detect the presence of gas leaks and sound an alarm.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Industrial Gas Fitter Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Industrial Gas Fitter Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Industrial Gas Fitter Helper is responsible for assisting Industrial Gas Fitters in the installation, maintenance, and repair of industrial gas systems. Key job responsibilities include:1. Assisting with Installation and Maintenance

Assisting with the installation, maintenance, and repair of industrial gas piping systems, including gas lines, valves, and fittings.

2. Material Handling

Loading, unloading, and transporting materials, tools, and equipment.

3. System Inspection

Conducting visual inspections of gas systems to identify potential leaks or damage.

4. Troubleshooting and Repairs

Assisting with troubleshooting and repairing gas leaks, malfunctions, and other system issues.

5. Safety Compliance

Following all safety protocols and regulations related to the handling and use of industrial gases.

Interview Tips

To prepare for an Industrial Gas Fitter Helper interview, consider the following tips:1. Research the Company and Position

Gather information about the company’s industry, size, and products or services.

2. Practice Common Interview Questions

Prepare answers to questions related to your experience, skills, and motivations.

3. Highlight Relevant Experience and Skills

Emphasize your previous experience in the industrial gas industry or related fields, such as plumbing or welding.

4. Demonstrate Strong Work Ethic and Safety Awareness

Highlight your ability to work hard, follow instructions, and prioritize safety.

5. Prepare Questions for the Interviewer

Asking thoughtful questions shows interest and engagement in the position and the company.

6. Dress Professionally and Arrive on Time

Professional attire and punctuality convey respect for the interviewer and the opportunity.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Industrial Gas Fitter Helper interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!