Are you gearing up for a career in Industrial Gas Fitter? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Industrial Gas Fitter and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

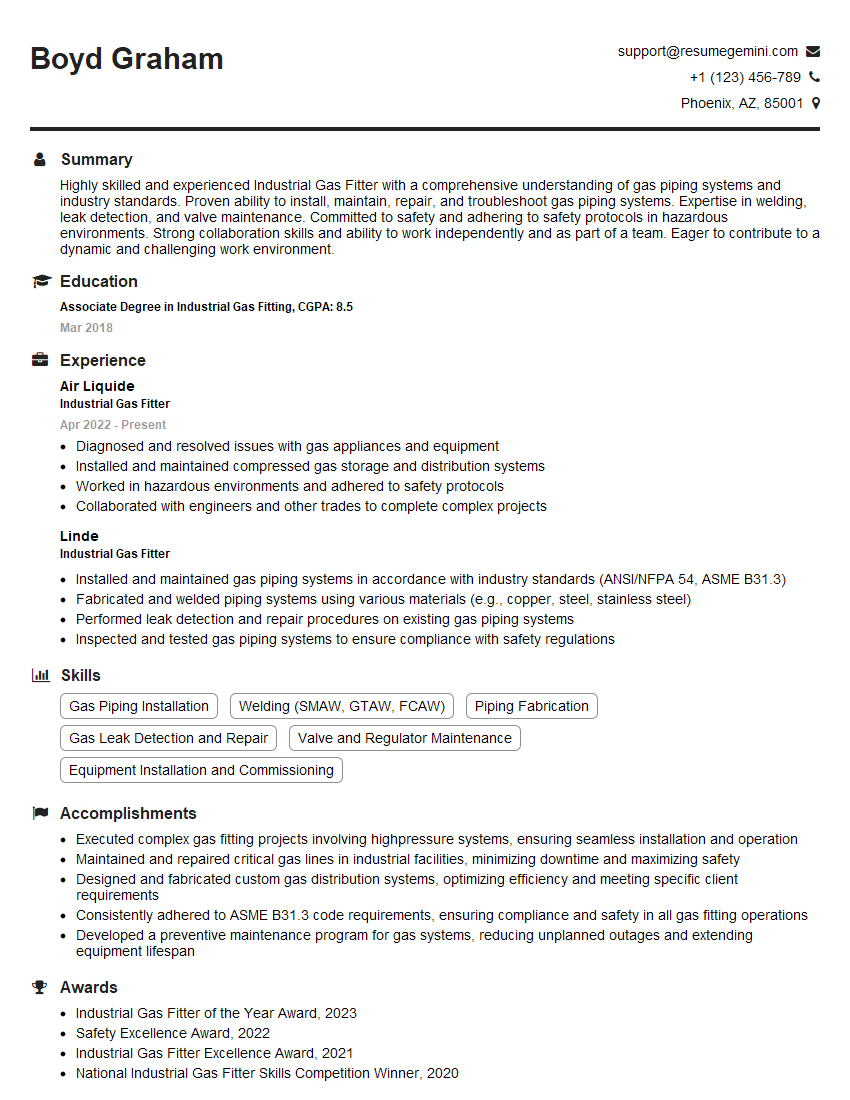

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Industrial Gas Fitter

1. What are the different types of gas fitting materials used in industrial applications?

Industrial gas fitters use a variety of materials to ensure the safe and efficient transmission of gases. These materials include:

- Copper: Copper is widely used in gas piping due to its excellent corrosion resistance, malleability, and durability. It is typically used in smaller diameter pipes for low-pressure applications.

- Stainless steel: Stainless steel is another common material for gas fitting, particularly in high-pressure and corrosive environments. It offers superior strength and resistance to rust and chemicals.

- Polyethylene (PE): PE is a flexible and lightweight material used for underground gas distribution. It is resistant to corrosion and cracking, making it suitable for long-term use.

- Polyvinyl chloride (PVC): PVC is another type of plastic material used in gas fitting. It is lightweight, cost-effective, and resistant to moisture and chemicals.

2. Describe the steps involved in installing a gas piping system.

Pre-installation

- Plan the system layout and obtain necessary permits.

- Gather materials and tools.

Installation

- Cut and thread pipes to the required lengths.

- Assemble valves, fittings, and piping using appropriate techniques.

- Secure pipes using clamps, supports, and hangers.

Testing and Commissioning

- Pressure test the system for leaks.

- Confirm proper flow rates and system operation.

3. What are the safety precautions to consider when working with industrial gases?

- Proper ventilation: Ensure adequate ventilation to prevent the accumulation of hazardous gases.

- Leak detection: Regularly check for gas leaks using appropriate detectors.

- Personal protective equipment (PPE): Wear appropriate PPE, including respiratory protection, gloves, and eye protection.

- Safe handling: Handle gas cylinders properly and securely, ensuring they are upright and not subjected to excessive heat or vibration.

- Emergency response: Be aware of emergency procedures and have emergency contacts readily available.

4. What are the key regulations and codes that govern industrial gas fitting?

- National Fuel Gas Code (NFPA 54): This code establishes minimum safety standards for the installation, maintenance, and operation of gas piping systems.

- Building codes: Local and regional building codes may have specific requirements for gas piping systems.

- Manufacturer’s guidelines: Gas appliances and equipment manufacturers provide specific instructions and safety guidelines that must be followed during installation.

- American Society of Mechanical Engineers (ASME) codes: ASME codes are widely used in the design, construction, and maintenance of boilers and pressure vessels used in gas systems.

5. What are the common troubleshooting techniques used to identify and resolve issues in gas piping systems?

- Pressure testing: Use a pressure gauge to identify leaks or blockages in the system.

- Flow testing: Measure gas flow rates to ensure proper system performance.

- Visual inspection: Examine pipes, fittings, and valves for signs of corrosion, damage, or improper installation.

- Gas leak detection: Use gas detectors to identify leaks in the system.

6. How do you ensure the quality of your work as an industrial gas fitter?

- Adherence to codes and standards: Follow established codes and safety regulations to ensure compliance and quality.

- Attention to detail: Pay meticulous attention to every aspect of the installation, including proper pipe sizing, layout, and fittings.

- Testing and inspection: Thoroughly test and inspect all systems before commissioning to identify and rectify any potential issues.

- Continuous learning: Stay updated on industry best practices, new technologies, and safety procedures to enhance your skills.

7. Describe your experience with different types of gas piping materials and their applications.

Throughout my career, I have worked with various gas piping materials, each with its unique properties and applications. Here are some examples:

- Copper: I have extensive experience installing and maintaining copper piping systems in residential, commercial, and industrial settings. I understand its corrosion resistance, malleability, and suitability for low-pressure applications.

- Stainless steel: I have worked on projects involving high-pressure gas systems and corrosive environments, where stainless steel is preferred for its strength and resistance to rust and chemicals.

- PE: I have installed PE gas piping for underground distribution networks. I am familiar with its flexibility, durability, and resistance to cracking, making it ideal for long-term use.

8. What is the importance of proper ventilation in gas piping systems?

- Safety: Proper ventilation prevents the accumulation of hazardous gases in enclosed spaces, ensuring the safety of workers and occupants.

- Performance: Adequate ventilation allows for the efficient combustion of gases in appliances and equipment, optimizing system performance and minimizing the risk of incomplete combustion.

- Code compliance: Building codes and safety regulations require proper ventilation to meet safety standards and prevent gas-related accidents.

9. Explain the process of pressure testing a gas piping system.

- Isolating the system: Close all valves and isolate the system from any gas sources.

- Connecting a pressure gauge: Attach a pressure gauge to a test point on the system.

- Applying pressure: Using a hand pump or other means, gradually increase the pressure in the system.

- Monitoring the pressure: Observe the pressure gauge for any drops or fluctuations that indicate a leak.

- Releasing pressure: Slowly release the pressure after the test is complete.

10. What are some common challenges you have faced as an industrial gas fitter and how did you overcome them?

One common challenge I have faced is working in confined spaces. In such situations, I carefully plan my work to minimize the time spent in the confined area. I use appropriate ventilation equipment and take regular breaks to ensure my safety and well-being.

Another challenge is handling high-pressure gas systems. I always follow established safety protocols, wear appropriate PPE, and work in a controlled environment to mitigate risks.

In the event of unforeseen circumstances, I remain calm and quickly assess the situation. I communicate effectively with my team and take prompt action to resolve the issue safely and efficiently.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Industrial Gas Fitter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Industrial Gas Fitter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Industrial gas fitters play a crucial role in the gas industry by ensuring the safe and efficient operation of industrial gas systems. Their responsibilities span across various aspects of gas fitting, including:

1. Installation and Maintenance

Installing, repairing, and maintaining industrial gas piping systems, valves, and equipment, ensuring adherence to safety regulations and industry standards.

- Inspecting and testing gas lines for leaks and potential hazards.

- Installing and configuring gas meters, regulators, and other control devices.

2. Troubleshooting and Repair

Diagnosing and resolving problems in industrial gas systems, ensuring efficient operation and minimizing downtime.

- Responding to emergency calls, isolating leaks, and taking appropriate corrective actions.

- Troubleshooting and repairing faulty components, such as valves, regulators, and piping.

3. Compliance and Safety

Ensuring compliance with all applicable regulations and safety standards related to industrial gas fitting.

- Conducting regular inspections and testing to ensure system integrity and adherence to safety protocols.

- Providing training and guidance to other personnel on gas safety procedures.

4. Documentation and Reporting

Maintaining accurate records of all work performed, including installation, maintenance, and repairs.

- Preparing technical reports, schematics, and drawings to document system modifications and repairs.

- Working closely with engineers and other professionals to ensure project completion and compliance.

Interview Tips

To ace an interview for an Industrial Gas Fitter position, candidates should focus on preparing thoroughly and presenting their skills and experience in a way that aligns with the job requirements. Here are some tips and hacks to help them succeed:

1. Research the Company and Industry

Research the company you’re applying to, their industry, and recent news or developments. This will help you tailor your answers to the specific context and demonstrate your interest in the company.

2. Highlight Relevant Skills and Experience

Carefully review the job description and identify the key skills and qualifications required for the role. Highlight your relevant skills, experience, and certifications in your resume and during the interview.

3. Prepare for Technical Questions

Be prepared to answer technical questions about industrial gas fitting, including installation, maintenance, troubleshooting, and safety protocols. Practice explaining your knowledge and provide specific examples of your work.

4. Emphasize Safety and Compliance

Safety is paramount in industrial gas fitting. Emphasize your commitment to safety and your knowledge of industry regulations and standards. Highlight your experience in conducting inspections, testing, and adhering to safety protocols.

5. Showcase Problem-Solving Abilities

Industrial gas fitters often encounter problems and challenges in their work. Provide examples of how you have successfully diagnosed and resolved issues in the past. This demonstrates your problem-solving abilities and practical experience.

6. Ask Informed Questions

At the end of the interview, ask informed questions that show your engagement and interest in the position and the company. This could include questions about growth opportunities, future projects, or the company’s commitment to training and development.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Industrial Gas Fitter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!