Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Industrial Insulator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Industrial Insulator so you can tailor your answers to impress potential employers.

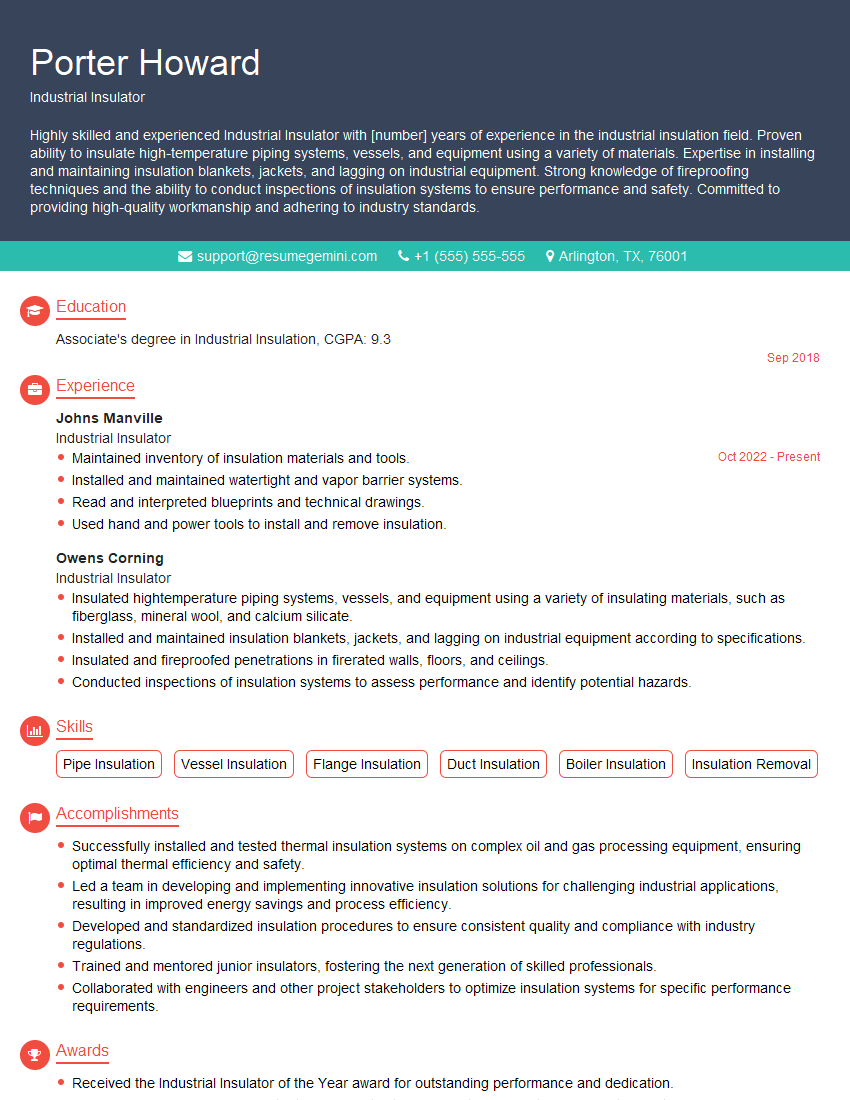

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Industrial Insulator

1. Explain the different types of insulating materials used in industrial applications?

Industrial insulators are materials used to prevent the flow of electricity between two conductors or between a conductor and the ground. The most common types of insulating materials used in industrial applications include:

- Polymers: These are organic materials that are made up of long chains of repeating units. They are typically used as electrical insulators because they have high dielectric strength and are resistant to heat and chemicals.

- Ceramics: These are inorganic materials that are made from clay, sand, and other minerals. They are typically used as electrical insulators because they have high dielectric strength and are resistant to heat and chemicals.

- Glass: This is an inorganic material that is made from sand, soda ash, and other minerals. It is typically used as an electrical insulator because it has high dielectric strength and is resistant to heat and chemicals.

- Composite materials: These are materials that are made from a combination of two or more different materials. They are often used as electrical insulators because they have the properties of both materials.

2. What are the factors to consider when selecting an insulating material for an industrial application?

Factors to consider when selecting an insulating material for an industrial application include:

- Dielectric strength: This is the ability of the material to resist the flow of electricity. The higher the dielectric strength, the better the material is at preventing electrical breakdown.

- Resistivity: This is the ability of the material to resist the flow of current. The higher the resistivity, the better the material is at preventing electrical leakage.

- Thermal conductivity: This is the ability of the material to conduct heat. The lower the thermal conductivity, the better the material is at preventing heat transfer.

- Chemical resistance: This is the ability of the material to resist the effects of chemicals. The better the chemical resistance, the longer the material will last in a harsh environment.

- Mechanical strength: This is the ability of the material to withstand physical stress. The higher the mechanical strength, the better the material is at resisting damage.

- Cost: The cost of the material is also an important factor to consider.

In addition to these factors, the following should also be considered:

- The operating temperature of the application

- The voltage of the application

- The frequency of the application

- The environmental conditions of the application

3. What are the different methods of applying insulation to industrial equipment?

There are a variety of methods used to apply insulation to industrial equipment. The most common methods include:

- Spraying: This method involves spraying a liquid or powder insulation material onto the equipment. The insulation material is then allowed to dry and cure.

- Pouring: This method involves pouring a liquid insulation material into the equipment. The insulation material is then allowed to dry and cure.

- Molding: This method involves molding a solid insulation material around the equipment. The insulation material is then allowed to cure.

- Wrapping: This method involves wrapping the equipment with a sheet of insulation material. The insulation material is then secured in place with tape or glue.

4. How do you test the insulation resistance of an industrial component?

The insulation resistance of an industrial component can be tested using a megohmmeter. A megohmmeter is a device that measures the resistance of an electrical component. To test the insulation resistance of a component, the megohmmeter is connected to the component and the resistance is measured. The resistance should be greater than the minimum insulation resistance specified by the manufacturer of the component.

5. What is the purpose of a dielectric test?

A dielectric test is a test that is performed to determine the ability of an insulating material to withstand electrical breakdown. The test is performed by applying a high voltage to the material and measuring the current that flows through the material. If the current is too high, the material will fail and the test will be considered a failure.

6. What are the different types of dielectric tests?

There are a variety of different dielectric tests that can be performed. The most common types of dielectric tests include:

- AC dielectric test: This test is performed by applying an AC voltage to the material and measuring the current that flows through the material.

- DC dielectric test: This test is performed by applying a DC voltage to the material and measuring the current that flows through the material.

- Impulse dielectric test: This test is performed by applying a high-voltage impulse to the material and measuring the current that flows through the material.

7. What are the different applications of industrial insulators?

Industrial insulators are used in a wide variety of applications. Some of the most common applications include:

- Electrical power distribution: Insulators are used to support and insulate electrical conductors in power distribution systems.

- Electrical equipment: Insulators are used to insulate electrical components in electrical equipment.

- Heat insulation: Insulators are used to insulate thermal equipment and processes.

- Sound insulation: Insulators are used to reduce noise levels in industrial environments.

8. What are the benefits of using industrial insulators?

There are a number of benefits to using industrial insulators. Some of the most common benefits include:

- Improved safety: Insulators help to prevent electrical shocks and fires.

- Increased efficiency: Insulators can help to improve the efficiency of electrical equipment by reducing energy losses.

- Extended lifespan: Insulators can help to extend the lifespan of electrical equipment by protecting it from damage.

- Reduced noise levels: Insulators can help to reduce noise levels in industrial environments.

9. What are the challenges of working with industrial insulators?

There are a number of challenges associated with working with industrial insulators. Some of the most common challenges include:

- Proper installation: Insulators must be properly installed in order to be effective. Improper installation can lead to electrical failures.

- Maintenance: Insulators must be properly maintained in order to ensure their continued effectiveness. Proper maintenance includes regular cleaning and testing.

- Environmental factors: Insulators can be affected by environmental factors such as temperature, humidity, and chemicals. These factors can degrade the performance of the insulators and lead to failure.

10. What is the future of industrial insulators?

The future of industrial insulators is bright. As the demand for electricity continues to grow, the need for insulators will also continue to grow. New materials and technologies are being developed that will make insulators more efficient, reliable, and cost-effective. This will lead to increased use of insulators in a variety of applications.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Industrial Insulator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Industrial Insulator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Industrial insulators play a crucial role in various industries, ensuring the safe and efficient operation of equipment and systems. Their responsibilities encompass a wide range of tasks, including:

1. Insulation Installation and Repair

Installing and repairing insulation materials on pipes, tanks, vessels, and other industrial equipment to prevent heat loss, condensation, and corrosion.

- Cutting, shaping, and fitting insulation materials to conform to equipment surfaces.

- Using adhesives, sealants, and other materials to secure insulation in place.

2. Inspection and Maintenance

Inspecting insulation systems regularly to identify any damage or deterioration and recommending necessary repairs.

- Performing routine maintenance tasks such as cleaning, tightening fasteners, and replacing damaged materials.

- Maintaining records of inspections and repairs.

3. Safety and Compliance

Ensuring compliance with safety regulations and industry standards related to insulation materials and installation practices.

- Wearing appropriate personal protective equipment (PPE).

- Following established work procedures and guidelines.

4. Troubleshooting and Problem-Solving

Diagnosing and resolving insulation-related problems that affect equipment performance or efficiency.

- Identifying the source of insulation failures or inefficiencies.

- Developing and implementing solutions to improve insulation performance.

Interview Tips

To ace an interview for an Industrial Insulator position, consider the following tips:

1. Research the Company and Position

Before the interview, thoroughly research the company and the specific job you’re applying for. This will help you understand their industry, products/services, and the role’s requirements.

- Visit the company’s website and social media pages.

- Read industry publications and articles about the company.

2. Highlight Relevant Skills and Experience

During the interview, emphasize your skills and experience that are directly relevant to the job responsibilities. Quantify your accomplishments whenever possible.

- For example, instead of saying “I installed insulation,” you could say “I installed insulation on over 100 pipes, resulting in a 15% reduction in heat loss.”

3. Prepare for Technical Questions

Be prepared to answer technical questions related to insulation materials, installation methods, and industry standards. These questions may include:

- What are the different types of insulation materials used in industry?

- How do you choose the right insulation material for a specific application?

4. Showcase Safety Awareness

Emphasize your commitment to safety and your knowledge of industry regulations. Highlight any safety training or certifications you possess.

- For example, mention that you have completed OSHA’s Hazard Communication Standard training.

5. Seek Information About the Company

At the end of the interview, ask questions about the company and the position to demonstrate your interest and engagement.

- Ask about the company’s growth plans or recent projects.

- Inquire about opportunities for professional development within the organization.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Industrial Insulator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.