Are you gearing up for a career in Industrial Machine System Technician? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Industrial Machine System Technician and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

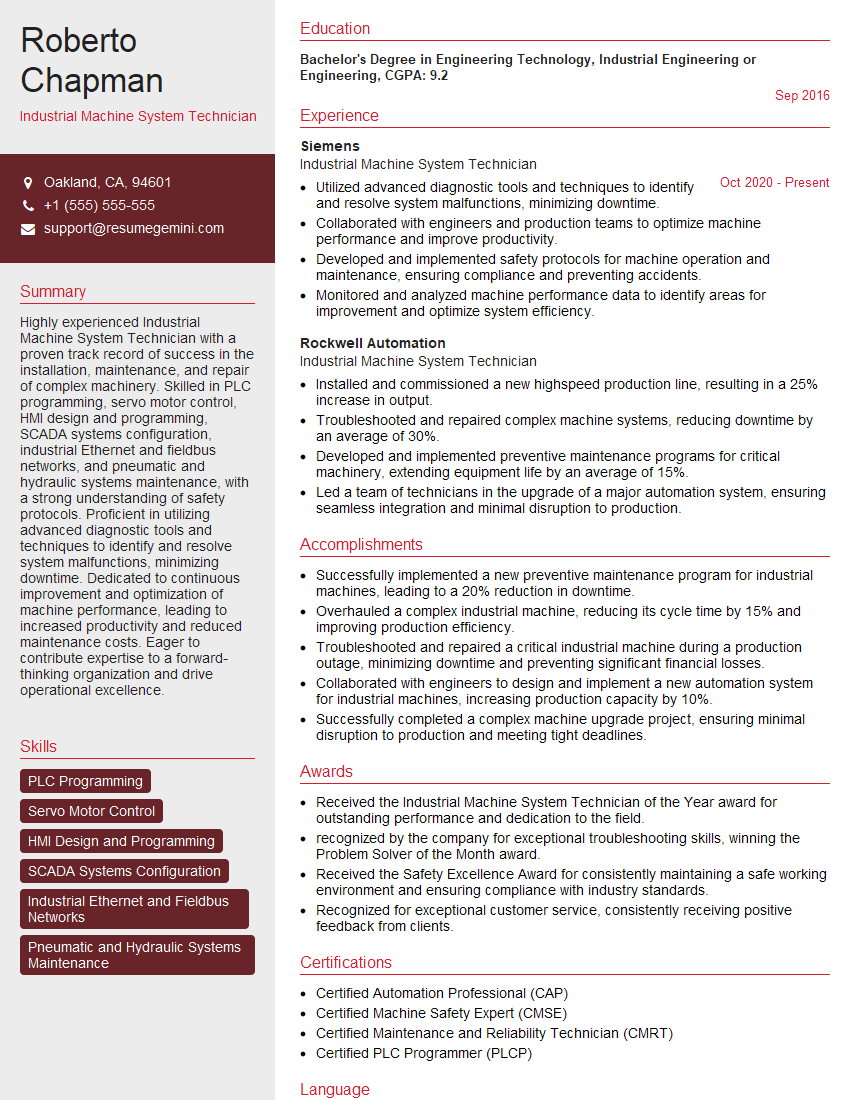

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Industrial Machine System Technician

1. Describe the process of troubleshooting a malfunctioning industrial machine.

To troubleshoot a malfunctioning industrial machine, I follow these steps:

- Identify the problem by observing the machine’s symptoms and gathering data from sensors or error messages.

- Analyze the data and determine the potential causes of the malfunction.

- Inspect the machine’s components, including electrical connections, mechanical parts, and hydraulic systems, to identify the source of the problem.

- Repair or replace the faulty components to resolve the malfunction.

- Test the machine to ensure it is functioning properly and make any necessary adjustments.

- Document the troubleshooting process and findings for future reference.

2. How do you ensure that an industrial machine is operating at optimal efficiency?

Preventive Maintenance

- Conduct regular inspections and maintenance tasks to ensure proper lubrication, alignment, and component integrity.

- Monitor machine performance data and identify any deviations from normal operating parameters.

Performance Monitoring

- Use sensors and data loggers to collect and analyze operating data, such as cycle times, energy consumption, and temperature.

- Identify bottlenecks and areas for improvement.

- Implement process optimization techniques to enhance efficiency.

3. What techniques do you use to identify potential hazards and mitigate risks in an industrial machine system?

- Conduct a thorough risk assessment to identify potential hazards associated with the machine.

- Implement safety measures, such as guarding, lockout/tagout procedures, and training for operators.

- Monitor machine performance and environmental conditions to detect any changes that could indicate potential risks.

- Stay up-to-date on industry best practices and regulations for safety.

4. Describe your experience with programming and operating industrial automation systems.

- Proficient in programming languages such as Ladder Logic, PLC, and HMI.

- Experience in designing, implementing, and troubleshooting automation systems for various industrial applications.

- Familiar with industry-standard communication protocols, such as Ethernet/IP, Modbus, and Profibus.

- Ability to integrate automation systems with sensors, actuators, and other industrial equipment.

5. How do you handle complex technical issues and collaborate with cross-functional teams?

- Approach complex issues with a systematic and analytical mindset.

- Consult with experts, research technical documentation, and explore multiple solutions.

- Effectively communicate technical concepts and findings to colleagues and team members.

- Collaborate with engineers, operators, and maintenance personnel to identify root causes and implement solutions.

- Document troubleshooting and repair processes for future reference and knowledge sharing.

6. What methods do you use to analyze and interpret diagnostic data from industrial machines?

- Use data analysis tools to extract meaningful insights from diagnostic data.

- Correlate data from multiple sources, including sensors, HMIs, and control systems.

- Identify trends, patterns, and anomalies in data to pinpoint potential issues.

- Apply statistical analysis and machine learning techniques to predict and prevent failures.

7. Describe your experience with predictive maintenance and condition monitoring techniques.

- Familiar with predictive maintenance principles and technologies.

- Experience in implementing condition monitoring systems, such as vibration analysis, thermography, and oil analysis.

- Ability to interpret data from condition monitoring systems to identify potential failures.

- Develop and implement maintenance strategies to minimize downtime and extend equipment lifespan.

8. What is your understanding of the latest advancements in industrial machine system technology?

- Stay informed about emerging technologies in the field, such as IoT, AI, and edge computing.

- Explore and evaluate new technologies for potential applications in industrial machine systems.

- Attend industry conferences and workshops to learn about best practices and innovations.

- Research and experiment with new technologies to enhance my skills and knowledge.

9. How do you ensure that your technical knowledge and skills remain up-to-date?

- Participate in ongoing training and professional development programs.

- Stay informed about industry trends and advancements through technical literature and online resources.

- Attend industry events, workshops, and conferences to network with experts and learn about best practices.

- Collaborate with colleagues and seek guidance from experienced professionals.

10. What motivates you to excel in the role of an Industrial Machine System Technician?

- Passion for solving technical challenges and optimizing industrial processes.

- Commitment to ensuring the reliability, safety, and efficiency of critical machine systems.

- Desire to contribute to the continuous improvement and innovation of industrial operations.

- Ability to work independently and as part of a team to achieve common goals.

- Drive to stay up-to-date with the latest advancements in the field.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Industrial Machine System Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Industrial Machine System Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of an Industrial Machine System Technician

As an Industrial Machine System Technician, you will:1. Install, Maintain, and Repair Industrial Machinery

This involves:

- Installing and commissioning new equipment

- Conducting regular maintenance and inspections

- Diagnosing and repairing malfunctions

2. Troubleshoot and Resolve Machine System Issues

You will:

- Analyze system data and identify potential issues

- Troubleshoot and resolve hardware and software problems

- Implement corrective actions to minimize downtime

3. Perform Preventive Maintenance and Calibration

To ensure optimal machine performance, you will:

- Conduct regular preventive maintenance

- Calibrate and adjust equipment to maintain precision

- Maintain maintenance records and documentation

4. Collaborate with Other Departments and Vendors

You will work closely with:

- Production and engineering teams

- External vendors and service providers

- Share knowledge and collaborate to resolve issues

Interview Preparation Tips for Industrial Machine System Technicians

1. Review the Job Description and Company Website

Before the interview, carefully analyze the job description and company website. This will give you insights into:

- Specific job requirements and responsibilities

- Company’s culture, values, and industry experience

2. Research Common Technical Interview Questions

Prepare for common technical questions related to:

- Industrial maintenance practices

- Machine system troubleshooting and repair techniques

- Calibration and preventive maintenance procedures

3. Practice STAR Method for Answer Formulation

The STAR method helps you provide concise and impactful answers:

- Situation: Describe the context or situation

- Task: Explain the specific task you were responsible for

- Action: Outline the steps you took to address the situation

- Result: Quantify the outcome and highlight your contribution

4. Highlight Relevant Experience and Skills

Emphasize your experience in:

- Industrial equipment installation, maintenance, and repair

- Diagnosing and resolving machine system issues

- Implementing preventive maintenance programs

5. Prepare Questions for the Interviewers

Asking well-thought-out questions demonstrates your interest and engagement. Prepare questions about:

- Company’s current and future projects

- Opportunities for professional development

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Industrial Machine System Technician role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.