Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Industrial Maintenance Repairer Helper position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

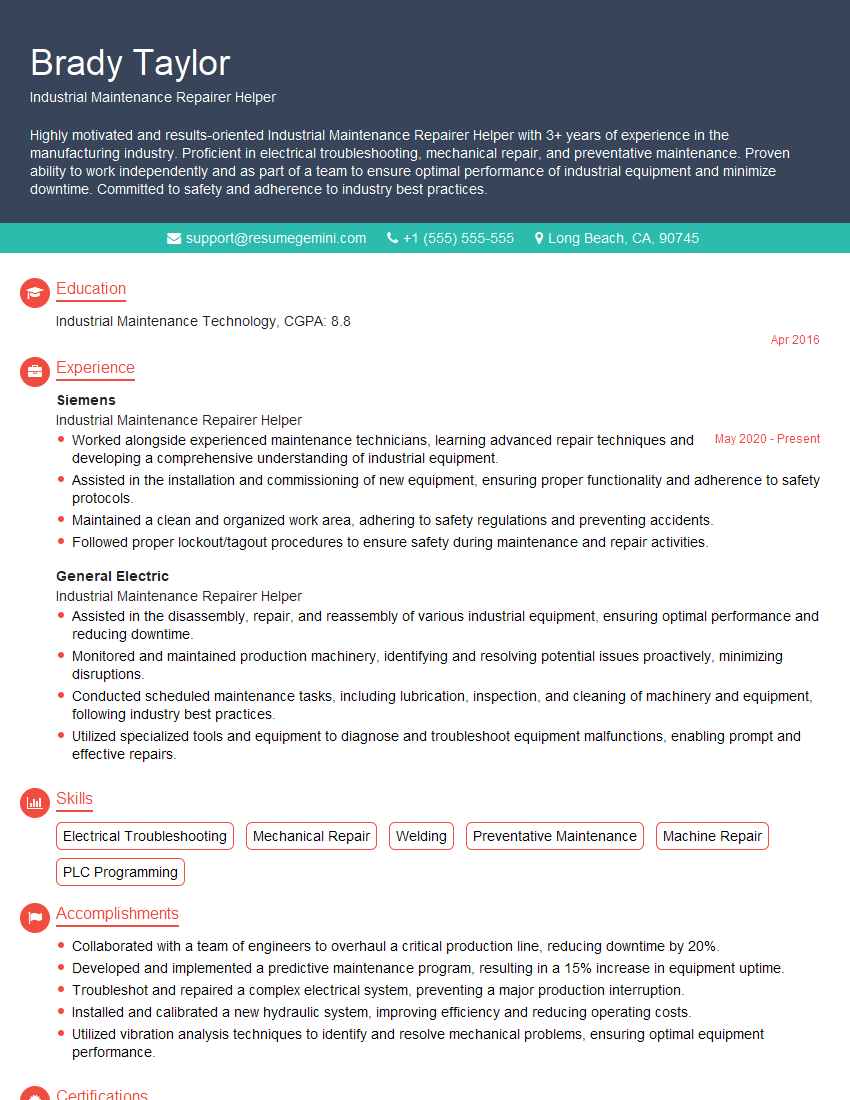

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Industrial Maintenance Repairer Helper

1. What are the essential tools and equipment commonly used by Industrial Maintenance Repairer Helpers?

As an Industrial Maintenance Repairer Helper, I am familiar with a wide range of tools and equipment essential for performing maintenance and repair tasks. These include:

- Hand tools: wrenches, pliers, screwdrivers, hammers, measuring tapes

- Power tools: drills, saws, grinders, sanders

- Specialized tools: torque wrenches, pressure gauges, vibration analyzers

- Safety equipment: hard hat, safety glasses, gloves, work boots

2. Explain the importance of following safety protocols in an industrial maintenance environment.

Adherence to Safety Regulations

- Prevents accidents and injuries

- Complies with legal requirements

Prevention of Equipment Damage

- Improper handling can lead to equipment malfunctions

- Safety measures protect equipment from damage

Maintenance of a Safe Work Environment

- Clear work areas and proper storage

- Minimizes hazards and promotes overall safety

3. Describe the process of troubleshooting and resolving electrical issues in industrial machinery.

Troubleshooting electrical issues involves a systematic approach:

- Identify the symptoms: Observe the malfunction and gather information

- Inspect visually: Check for loose connections, damaged wires, or visible faults

- Test and diagnose: Use multimeters and other diagnostic tools to isolate the issue

- Repair or replace: Fix the faulty components or replace them as necessary

- Verify and test: Ensure the repair has resolved the issue and conduct safety tests

4. What steps do you take to ensure the proper lubrication of industrial machinery?

Lubrication is crucial for machinery maintenance:

- Determine lubrication requirements: Refer to manufacturer’s recommendations

- Select the appropriate lubricant: Consider the type of machinery and operating conditions

- Apply lubricant correctly: Follow specified quantities and intervals

- Monitor lubrication levels: Regularly check oil levels and replenish as needed

- Inspect for leaks: Identify and address any lubrication leaks promptly

5. How do you prioritize maintenance tasks when multiple issues arise simultaneously?

Prioritizing maintenance tasks requires a structured approach:

- Assess urgency: Determine which issues pose the greatest risk or downtime impact

- Consider consequences: Evaluate the potential damage or production loss if issues are not addressed

- Analyze dependencies: Identify any tasks that must be completed before others can commence

- Communicate effectively: Inform supervisors or maintenance teams about the prioritization

- Monitor and adjust: Regularly review the situation and make adjustments to the prioritization as needed

6. How do you stay updated on the latest maintenance techniques and technologies?

Continuously improving my knowledge is essential for staying up to date:

- Attend training sessions: Participate in workshops and conferences

- Read industry publications: Stay informed through trade journals and online resources

- Network with professionals: Connect with colleagues and attend industry events

- Utilize online learning platforms: Take advantage of e-learning courses and webinars

7. Describe your experience in working with computerized maintenance management systems (CMMS).

I have experience using CMMS systems to:

- Track maintenance requests and work orders

- Manage inventory and spare parts

- Schedule maintenance activities

- Generate reports and analyze maintenance data

8. How do you ensure that repaired equipment meets safety and quality standards?

To ensure safety and quality, I follow these steps:

- Adhere to manufacturer’s specifications

- Use calibrated tools and equipment

- Conduct thorough inspections and testing

- Document all repairs and maintenance activities

- Obtain approval from authorized personnel before releasing equipment

9. How do you handle working in a team environment with other maintenance personnel?

Working in a team requires effective communication and collaboration:

- Respect different perspectives and expertise

- Share information and knowledge openly

- Support colleagues and assist with tasks

- Contribute to decision-making processes

- Maintain a positive and supportive work environment

10. What motivates you to work as an Industrial Maintenance Repairer Helper?

I am motivated by the opportunity to:

- Contribute to the smooth operation of industrial facilities

- Apply my technical skills and knowledge to solve problems

- Learn and grow within the maintenance field

- Make a positive impact on the organization’s productivity and efficiency

- Work in a challenging and rewarding environment

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Industrial Maintenance Repairer Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Industrial Maintenance Repairer Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Industrial Maintenance Repairer Helpers provide assistance to Industrial Maintenance Repairers in the maintenance and repair of machinery and equipment in various industrial settings.

1. Assist Industrial Maintenance Repairers

Assist Industrial Maintenance Repairers with troubleshooting, servicing, repairing, and maintaining plant equipment and machinery

- Collect tools, equipment, and materials needed for repair tasks

- Assist with the disassembly and assembly of machinery and equipment for repairs

2. Conduct Inspection and Monitoring

Inspect and monitor equipment to identify potential problems and ensure proper operation

- Take routine readings to monitor equipment performance

- Report any abnormalities or potential issues to Industrial Maintenance Repairers

3. Assist with Preventive Maintenance

Assist in the implementation and execution of preventive maintenance programs to prevent breakdowns and ensure equipment longevity

- Perform routine maintenance tasks, such as lubrication, cleaning, and minor adjustments

- Keep records of maintenance activities and repairs

4. Follow Safety Protocols

Maintain a safe work environment by following established safety protocols and procedures

- Adhere to personal protective equipment requirements

- Identify and report potential hazards

Interview Tips

Preparation is key to acing an interview. Here are some tips to help you make a great impression and land the job:

1. Research the Company and Position

Research the company’s website, LinkedIn page, and industry news to gain insights into their culture, values, and recent developments. Understand the specific requirements of the Industrial Maintenance Repairer Helper role and how your skills and experience align with them.

- Tailor your answers to demonstrate how you meet the qualifications and can contribute to the company’s goals.

- Example Outline:

- Q: Tell me about your experience in assisting with industrial maintenance and repair tasks.

- A: In my previous role, I assisted an Industrial Maintenance Repairer with the disassembly and reassembly of machinery for repairs. I was responsible for collecting and organizing tools, equipment, and materials needed for the task. I also assisted with the troubleshooting and repair of various plant equipment.

2. Practice Your Answers

Prepare for common interview questions by practicing your answers aloud. This will help you articulate your thoughts clearly and confidently. Consider using the STAR method (Situation, Task, Action, Result) to structure your responses and provide specific examples of your skills and accomplishments.

- Example Outline:

- Q: Describe a time when you identified a potential issue during an inspection.

- A: During a routine inspection, I noticed abnormal vibrations coming from a particular machine. I immediately reported this to my supervisor, who then scheduled a more thorough inspection and maintenance.

3. Highlight Relevant Skills and Experience

Emphasize your technical skills, such as familiarity with industrial tools, equipment, and machinery. Highlight your ability to follow safety protocols and work effectively in a team environment. If you have experience with preventive maintenance programs or certifications in relevant areas, be sure to mention them.

- Example Outline:

- Q: What are your strengths as an Industrial Maintenance Repairer Helper?

- A: My strengths include my attention to detail, strong work ethic, and ability to work independently. I am also proficient in using various tools and equipment and have a good understanding of preventive maintenance practices.

4. Be Enthusiastic and Professional

Throughout the interview, maintain a positive and enthusiastic attitude. Show that you are genuinely interested in the opportunity and the company. Be respectful and professional in your interactions, and ask thoughtful questions to demonstrate your engagement and interest in the role.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Industrial Maintenance Repairer Helper interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.