Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Industrial Radiographer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Industrial Radiographer so you can tailor your answers to impress potential employers.

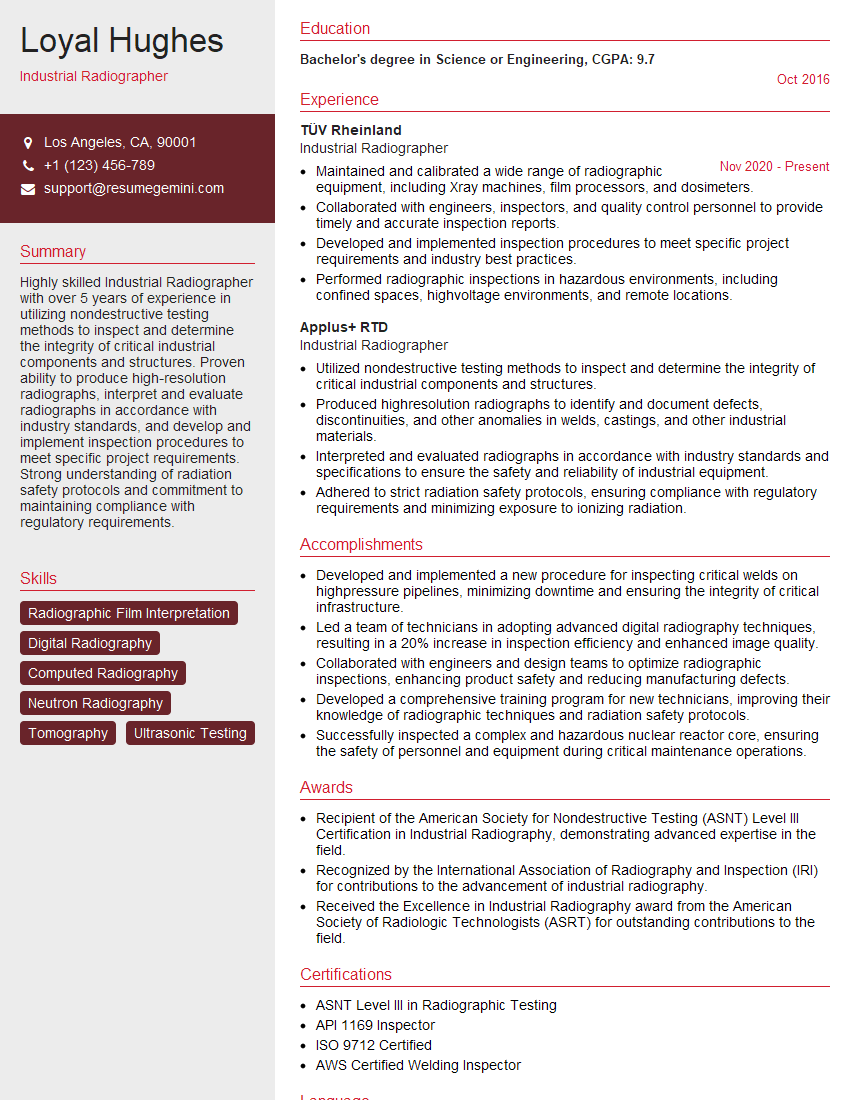

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Industrial Radiographer

1. What are the different types of radiographic techniques used in industrial radiography?

There are several radiographic techniques commonly used in industrial radiography:

- Contact Radiography: The X-ray source is placed directly on the object, providing the highest image resolution.

- Projection Radiography: The X-ray source is positioned at a distance from the object, creating a magnified image.

- Microradiography: Uses high-resolution X-rays to examine small or thin objects, enabling detailed analysis.

- Fluoroscopy: A dynamic technique that allows real-time observation of moving objects or processes.

- Computed Tomography (CT): A 3D imaging technique that provides cross-sectional views of the object.

2. Describe the process of film processing in industrial radiography.

Film Loading

- Load the film into a protective cassette or holder.

- Ensure proper alignment and orientation.

Exposure to Radiation

- Expose the film to X-rays or gamma rays from the radiographic source.

- Control the exposure time and intensity based on the object and inspection requirements.

Processing

- Develop the film using a series of chemical baths to convert the exposed silver halide crystals into black metallic silver.

- Rinse, fix, and wash the film to remove residual chemicals and stabilize the image.

3. What are the various factors that affect the quality of a radiographic image?

- X-ray Source: Energy, intensity, and focus

- Object Properties: Thickness, density, and atomic number

- Exposure Parameters: Time, distance, and angle

- Film Characteristics: Sensitivity, grain size, and contrast

- Processing Conditions: Temperature, time, and chemistry

4. How do you interpret radiographic images and identify defects?

Interpreting radiographic images involves analyzing the density, shape, and location of the shadows:

- Density: Dark areas indicate thicker or denser regions, while light areas indicate thinner or less dense regions.

- Shape: Defects may appear as cracks, voids, inclusions, or other anomalies in the material’s structure.

- Location: The position of the defect within the image provides information about its depth and severity.

5. What are the safety precautions that must be followed when working with X-rays and radioactive materials?

- Radiation Shielding: Use lead curtains, screens, or barriers to absorb radiation.

- Personal Protective Equipment (PPE): Wear appropriate clothing, gloves, and dosimeters to monitor exposure.

- Monitoring and Control: Follow established protocols for handling radioactive sources and disposing of contaminated materials.

- Training: Receive proper safety training and certification in radiation protection.

- Emergency Procedures: Know and follow procedures in case of accidents or emergencies.

6. Describe the different non-destructive testing (NDT) methods commonly used in industrial inspections, apart from radiography.

- Ultrasonic Testing (UT): Uses sound waves to detect defects and measure thickness.

- Magnetic Particle Testing (MT): Detects surface-breaking cracks using magnetic fields and ferromagnetic particles.

- Eddy Current Testing (ET): Examines conductive materials for surface and subsurface defects using electromagnetic fields.

- Acoustic Emission Testing (AE): Monitors sound emissions to identify and locate active defects during structural testing.

- Dye Penetrant Testing (PT): Reveals surface-breaking cracks or defects using a fluorescent or visible dye.

7. Can you explain the principles behind computed tomography (CT) and its advantages in industrial radiography?

Computed tomography (CT) combines multiple radiographic images taken at different angles to create cross-sectional views:

- Principles: X-rays are passed through the object at various angles, and the resulting data is processed using computer algorithms.

- Advantages:

- 3D visualization of internal structures

- Improved defect detection and characterization

- Non-destructive analysis of complex geometries

8. How do you maintain and calibrate equipment used in industrial radiography?

- X-ray Sources: Regular voltage and current checks, leakage tests, and maintenance of cooling systems.

- Radiographic Cameras: Calibration of geometric parameters, such as source-to-film distance and alignment.

- Film Processors: Temperature and chemical bath monitoring, replenishment, and regular cleaning.

- Dosimeters: Calibration to ensure accurate radiation exposure measurements.

- Follow Established Protocols: Adhere to manufacturer’s recommendations and industry standards for maintenance and calibration.

9. What are the latest advancements in industrial radiography technology?

- Digital Radiography (DR): Uses digital detectors to capture and process images, providing enhanced image quality and real-time analysis.

- Computed Tomography (CT) Scanning: Advanced algorithms and high-resolution CT scanners enable detailed 3D visualization.

- Artificial Intelligence (AI): AI-based algorithms support image interpretation, defect classification, and automated reporting.

- Remote Radiography: Enables remote monitoring and analysis of radiographic data.

- Miniaturized X-ray Sources: Portable and compact X-ray sources for inspections in confined spaces and field applications.

10. Can you explain the role of industrial radiography in ensuring the safety and reliability of critical infrastructure, such as bridges and pipelines?

Industrial radiography plays a vital role in maintaining the safety and integrity of critical infrastructure:

- Bridge Inspections: Detects cracks, corrosion, and other defects in bridge components, ensuring structural integrity.

- Pipeline Inspections: Identifies corrosion, leaks, and blockages in pipelines, preventing potential accidents and environmental hazards.

- Welding Verification: Assesses the quality of welds in pressure vessels and other safety-critical components.

- Materials Inspection: Determines the composition, structure, and integrity of materials used in construction and manufacturing.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Industrial Radiographer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Industrial Radiographer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Industrial Radiographers hold a crucial role in the identification and rectification of flaws in critical industrial components and structures, ensuring their safety and reliability.

1. Non-Destructive Testing (NDT) Inspection

Conduct non-destructive testing (NDT) inspections using radiographic techniques, mainly X-rays and gamma rays, to detect and assess internal flaws, cracks, or defects.

- Prepare and calibrate NDT equipment, including X-ray tubes, gamma sources, and detectors.

- Develop and execute inspection plans based on project specifications and safety standards.

2. Radiation Safety Protocols

Prioritize and adhere to strict radiation safety protocols to ensure the protection of the environment, personnel, and general public.

- Maintain a safe working environment by monitoring radiation levels, imposing appropriate access restrictions, and following radiation safety guidelines.

- Wear personal protective equipment (PPE) consistently.

3. Image Analysis and Reporting

Process and interpret radiographic images to identify and document defects or anomalies in target materials.

- Generate comprehensive inspection reports, including images, measurements, and defect analysis summaries.

- Provide technical recommendations for corrective actions or further investigations when necessary.

4. Collaboration and Communication

Collaborate with engineers, technicians, and other stakeholders to communicate inspection findings, provide technical support, and ensure project efficiency.

- Attend project meetings and present inspection results.

- Participate in training and educational programs to stay abreast of new technologies and industry best practices.

Interview Tips

Preparing thoroughly for your interview can significantly increase your chances of success. Here are some essential tips to help you ace your interview as an Industrial Radiographer:

1. Research the Company and Position

Take the time to research the company’s background, values, and current projects. Understanding their industry, clientele, and specific needs will allow you to tailor your responses and demonstrate your suitability for the role.

- Visit the company’s website and social media pages to gather relevant information.

- Read industry-specific articles and news to familiarize yourself with the latest trends and challenges.

2. Practice Your Technical Skills

Practice explaining technical concepts and methodologies related to radiographic testing. Be prepared to discuss your expertise in image acquisition, interpretation, and reporting.

- Review the principles of radiography, radiation safety protocols, and different NDT methods.

- Prepare examples of successful projects where you applied your technical abilities to solve complex problems.

3. Highlight Your Safety Consciousness

Emphasize your commitment to radiation safety and your understanding of the regulations and protocols involved in handling radioactive materials.

- Describe your experience in following radiation safety procedures and maintaining a safe working environment.

- Mention any certifications or training programs you have completed in radiation safety.

4. Showcase Your Communication and Collaboration Skills

Industrial Radiographers often work in collaborative environments. Demonstrate your ability to communicate effectively, both verbally and in writing, and highlight your experience in working with engineers, technicians, and other stakeholders.

- Provide examples of how you have successfully collaborated with team members to complete projects efficiently.

- Discuss your approach to presenting technical information to non-technical audiences.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Industrial Radiographer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.